Splicing with Solder and Potting Compound

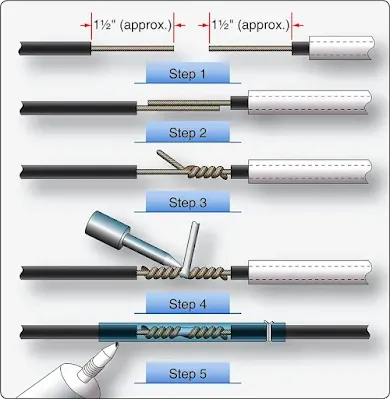

When neither a permanent splice nor a terminal lug is available, a broken wire can be repaired as follows [Figure]:

- Install a piece of plastic sleeving about 3 inches long and of the proper diameter to fit loosely over the insulation on one piece of the broken wire.

- Strip approximately 1½ inches from each broken end of the wire.

- Lay the stripped ends side by side and twist one wire around the other with approximately four turns.

- Twist the free end of the second wire around the first wire with approximately four turns. Solder the wire turns together using 60/40 tin-lead resin-core solder.

- When solder is cool, draw the sleeve over the soldered wires and tie at one end. If potting compound is available, fill the sleeve with potting material and tie securely.

- Allow the potting compound to set without touching for 4 hours. Full cure and electrical characteristics are achieved in 24 hours.

|

| Repairing broken wire by soldering and potting |