Bonding is the electrical connecting of two or more conducting objects not otherwise connected adequately. Grounding is the electrical connecting of a conducting object to the primary structure for return of current. Primary structure is the main frame, fuselage, or wing structure of the aircraft. Bonding and grounding connections are made in aircraft electrical systems to:

- Protect aircraft and personnel against hazards from lightning discharge,

- Provide current return paths,

- Prevent development of radio-frequency potentials,

- Protect personnel from shock hazard,

- Provide stability of radio transmission and reception, and

- Prevent accumulation of static charge.

General Bonding and Grounding Procedures

The following general procedures and precautions are recommended when making bonding or grounding connections.

- Bond or ground parts to the primary aircraft structure, where practicable.

- Make bonding or grounding connections in such a manner that no part of the aircraft structure is weakened.

- Bond parts individually, if possible.

- Install bonding or grounding connections against smooth, clean surfaces.

- Install bonding or grounding connections so that vibration, expansion or contraction, or relative movement in normal service does not break or loosen the connection.

- Install bonding and grounding connections in protected areas whenever possible.

Bonding jumpers should be kept as short as practicable, and installed so that the resistance of each connection does not exceed 0.003 ohm. The jumper should not interfere with the operation of movable aircraft elements, such as surface controls; normal movement of these elements should not result in damage to the bonding jumper.

To be sure a low resistance connection has been made, nonconducting finishes, such as paint and anodizing films, should be removed from the surface to be contacted by the bonding terminal.

Electrolytic action can rapidly corrode a bonding connection if suitable precautions are not observed. Aluminum alloy jumpers are recommended for most cases; however, copper jumpers can be used to bond together parts made of stainless steel, cadmium-plated steel, copper, brass, or bronze. Where contact between dissimilar metals cannot be avoided, the choice of jumper and hardware should be such that corrosion is minimized, and the part most likely to corrode is the jumper or associated hardware. Parts A and B of Figure 1 illustrate some proper hardware combinations for making bonding connections. At locations where finishes are removed, a protective finish should be applied to the completed connection to prevent corrosion.

|

| Figure 1. Hardware combinations used in making bonding connections |

The use of solder to attach bonding jumpers should be avoided. Tubular members should be bonded by means of clamps to which the jumper is attached. The proper choice of clamp material minimizes the probability of corrosion. When bonding jumpers carry a substantial amount of ground return current, the current rating of the jumper should be adequate, and it should be determined that a negligible voltage drop is produced.

Bonding and grounding connections are normally made to flat surfaces by means of through-bolts or screws where there is easy access for installation. The general types of bolted connections are:

- In making a stud connection, a bolt or screw is locked securely to the structure becoming a stud. [Figure 2] Grounding or bonding jumpers can be removed or added to the shank of the stud without removing the stud from the structure.

|

| Figure 2. Stud bonding or grounding to a flat surface |

- Nutplates are used where access to the nut for repairs is difficult. Nutplates are riveted or welded to a clean area of the structure. [Figure 3]

|

| Figure 3. Nut plate bonding or grounding to flat surface |

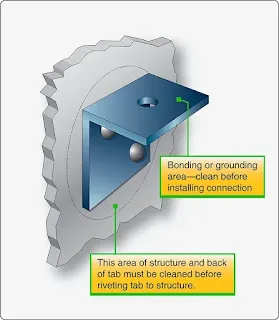

Bonding and grounding connections are also made to a tab riveted to a structure. [Figure 4] In such cases, it is important to clean the bonding or grounding surface and make the connection as though the connection were being made to the structure. If it is necessary to remove the tab for any reason, the rivets should be replaced with rivets one size larger, and the mating surfaces of the structure and the tab should be clean and free of anodic film.

|

| Figure 4. Bonding or grounding tab riveted to structure |

Bonding or grounding connections can be made to aluminum alloy, magnesium, or corrosion-resistant steel tubular structure. Figure 5 shows the arrangement of hardware for bonding with an aluminum jumper. Because of the ease with which aluminum is deformed, it is necessary to distribute screw and nut pressure by means of plain washers.

|

| Figure 5. Bonding or grounding connections to a cylindrical structure |

Hardware used to make bonding or grounding connections should be selected on the basis of mechanical strength, current to be carried, and ease of installation. If connection is made by aluminum or copper jumpers to the structure of a dissimilar material, a washer of suitable material should be installed between the dissimilar metals so that any corrosion occurs on the washer.

Hardware material and finish should be selected on the basis of the material of the structure to which attachment is made and on the material of the jumper and terminal specified for the bonding or grounding connection. Either a screw or bolt of the proper size for the specified jumper terminal should be used. When repairing or replacing existing bonding or grounding connections, the same type of hardware used in the original connection should always be used.