|

| Figure 1. Diesel liquid-cooled aircraft engine |

In a liquid-cooled engine, around the cylinder are water jackets, in which liquid coolant is circulated and the coolant takes away the excess heat. The excess heat is then dissipated by a heat exchanger or radiator using air flow. Turbine engines use secondary airflow to cool the inside components and many of the exterior components.

Reciprocating Engine Cooling Systems

An internal-combustion engine is a heat machine that converts chemical energy in the fuel into mechanical energy at the crankshaft. It does not do this without some loss of energy, however, and even the most efficient aircraft engines may waste 60 to 70 percent of the original energy in the fuel. Unless most of this waste heat is rapidly removed, the cylinders may become hot enough to cause complete engine failure. Excessive heat is undesirable in any internal-combustion engine for three principal reasons:

[ad-long]

[ad-longer]

[ad-longest]

- It affects the behavior of the combustion of the fuel/ air charge.

- It weakens and shortens the life of engine parts.

- It impairs lubrication.

If the temperature inside the engine cylinder is too great, the fuel-air mixture is preheated, and combustion occurs before the desired time. Since premature combustion causes detonation, knocking, and other undesirable conditions, there must be a way to eliminate heat before it causes damage.

One gallon of aviation gasoline has enough heat value to boil 75 gallons of water; thus, it is easy to see that an engine that burns 4 gallons of fuel per minute releases a tremendous amount of heat. About one-fourth of the heat released is changed into useful power. The remainder of the heat must be dissipated so that it is not destructive to the engine. In a typical aircraft powerplant, half of the heat goes out with the exhaust and the other is absorbed by the engine. Circulating oil picks up part of this soaked-in heat and transfers it to the airstream through the oil cooler. The engine cooling system takes care of the rest. Cooling is a matter of transferring the excess heat from the cylinders to the air, but there is more to such a job than just placing the cylinders in the airstream. A cylinder on a large engine is roughly the size of a gallon jug. Its outer surface, however, is increased by the use of cooling fins so that it presents a barrel-sized exterior to the cooling air. Such an arrangement increases the heat transfer by radiation. If too much of the cooling fin area is broken off, the cylinder cannot cool properly, and a hotspot develops. Therefore, cylinders are normally replaced if a specified number of square inches of fins are missing.

Cowling and baffles are designed to force air over the cylinder cooling fins. [Figure 2] The baffles direct the air close around the cylinders and prevent it from forming hot pools of stagnant air while the main streams rush by unused. Blast tubes are built into the baffles to direct jets of cooling air onto the rear spark plug elbows of each cylinder to prevent overheating of ignition leads.

|

| Figure 2. Cylinder baffle and deflector system |

An engine can have an operating temperature that is too low. For the same reasons that an engine is warmed up before takeoff, it is kept warm during flight. Fuel evaporation and distribution and oil circulation depend on an engine being kept at its optimum operating temperature. The aircraft engine has temperature controls that regulate air circulation over the engine. Unless some controls are provided, the engine could overheat on takeoff and get too cold in high altitude, high-speed and low-power letdowns.

[ad-mid]

The most common means of controlling cooling is the use of cowl flaps. [Figure 3] These flaps are opened and closed by electric motor-driven jackscrews, by hydraulic actuators, or manually in some light aircraft. When extended for increased cooling, the cowl flaps produce drag and sacrifice streamlining for the added cooling. On takeoff, the cowl flaps are opened only enough to keep the engine below the red-line temperature. Heating above the normal range is allowed so that drag is as low as possible. During ground operations, the cowl flaps should be opened wide since drag does not matter and cooling needs to be set at maximum. Cowl flaps are used mostly with older aircraft and radial engine installations.

|

| Figure 3. Regulating the cooling airflow |

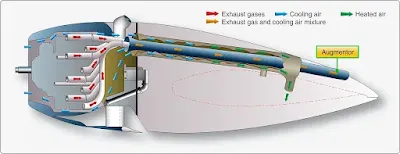

Some aircraft use augmentors to provide additional cooling airflow. [Figure 4] Each nacelle has two pairs of tubes running from the engine compartment to the rear of the nacelle. The exhaust collectors feed exhaust gas into the inner augmentor tubes. The exhaust gas mixes with air that has passed over the engine and heats it to form a high-temperature, low-pressure, jet-like exhaust. This low-pressure area in the augmentors draws additional cooling air over the engine. Air entering the outer shells of the augmentors is heated through contact with the augmentor tubes but is not contaminated with exhaust gases. The heated air from the shell goes to the cabin heating, defrosting, and anti-icing system.

|

| Figure 4. Augmentor |

Augmentors use exhaust gas velocity to cause airflow over the engine so that cooling is not entirely dependent on the prop wash. Vanes installed in the augmentors control the volume of air. These vanes are usually left in the trail position to permit maximum flow. They can be closed to increase the heat for cabin or anti-icing use or to prevent the engine from cooling too much during descent from altitude. In addition to augmentors, some aircraft have residual heat doors or nacelle flaps that are used mainly to let the retained heat escape after engine shutdown. The nacelle flaps can be opened for more cooling than that provided by the augmentors. A modified form of the previously described augmentor cooling system is used on some light aircraft. [Figure 5] Augmentor systems are not used much on modern aircraft.

|

| Figure 5. Engine cooling and exhaust system |

As shown in Figure 5, the engine is pressure cooled by air taken in through two openings in the nose cowling, one on each side of the propeller spinner. A pressure chamber is sealed off on the top side of the engine with baffles properly directing the flow of cooling air to all parts of the engine compartment. Warm air is drawn from the lower part of the engine compartment by the pumping action of the exhaust gases through the exhaust ejectors. This type of cooling system eliminates the use of controllable cowl flaps and assures adequate engine cooling at all operating speeds.

[ad-long]

Reciprocating Engine Cooling System Maintenance

The engine cooling system of most reciprocating engines usually consists of the engine cowling, cylinder baffles, cylinder fins, and some use a type of cowl flaps. In addition to these major units, there are also some temperature-indicating systems, such as cylinder head temperature, oil temperature, and exhaust gas temperature.

The cowling performs two functions:

- It streamlines the bulky engine to reduce drag.

- It forms an envelope around the engine that forces air to pass around and between the cylinders, absorbing the heat dissipated by the cylinder fins.

The cylinder bases are metal shields, designed and arranged to direct the flow of air evenly around all cylinders. This even distribution of air aids in preventing one or more cylinders from being excessively hotter than the others. The cylinder fins radiate heat from the cylinder walls and heads. As the air passes over the fins, it absorbs this heat, carries it away from the cylinder, and is exhausted overboard through the bottom rear of the cowl.

The controllable cowl flaps provide a means of decreasing or increasing the exit area at the rear of the engine cowling. [Figure 6]

|

| Figure 6. Small aircraft cowl flaps |

Closing the cowl flaps decreases the exit area, which effectively decreases the amount of air that can circulate over the cylinder fins. The decreased airflow cannot carry away as much heat; therefore, there is a tendency engine temperature tends to increase. Opening the cowl flaps makes the exit area larger. The flow of cooling air over the cylinders increases, absorbing more heat and the engine temperature tends to decrease. Good inspection and maintenance in the care of the engine cooling system aids in overall efficient and economical engine operation.

Maintenance of Engine Cowling

Of the total ram airflow approaching the airborne engine nacelle, only about 15 to 30 percent enters the cowling to provide engine cooling. The remaining air flows over the outside of the cowling. Therefore, the external shape of the cowl must be faired in a manner that permits the air to flow smoothly over the cowl with a minimum loss of energy.

The engine cowling discussed in this section is typical of that used on many radial or horizontally opposed engines. All cooling systems function in the same manner, with minor engineering changes designed for specific installations.

The cowl is manufactured in removable sections, the number varies with the aircraft make and model. The installation shown in Figure 7 contains two sections that are locked together when installed.

|

| Figure 7. Differential air cooling |

The cowl panels, made from sheet aluminum or composite material, have a smooth external surface to permit undisturbed airflow over the cowl. The internal construction is designed to give strength to the panel and, in addition, to provide receptacles for the toggle latches, cowl support, and engine air seal.

An air seal is constructed of rubber material, bolted to a metal rib riveted to the cowl panel. [Figure 7] This seal, as the name implies, seals the air in the engine section, preventing the air from escaping along the inner surface of the panel without circulating around the cylinders. The engine air seal must be used on engines that have a complete cylinder baffling system that covers the cylinder heads. Its purpose is to force the air to circulate around and through the baffle system. Inspect the cowl panels during each regular engine and aircraft inspection. Removing the cowling for maintenance provides an opportunity for more frequent inspection of the cowling.

Inspect the cowling panels for scratches, dents, and tears in the panels. This type of damage causes weakness of the panel structure, increases drag by disrupting airflow, and contributes to the starting of corrosion. The cowling panel latches should be inspected for pulled rivets and loose or damaged handles. The internal construction of the panel should be examined to see that the reinforcing ribs are not cracked and that the air seal is not damaged. The cowl flap hinges, if equipped, and cowl flap hinge bondings should be checked for security of mounting and for breaks or cracks. These inspections are visual checks and should be performed frequently to ensure that the cowling is serviceable and is contributing to efficient engine cooling.

[ad-longer]

Engine Cylinder Cooling Fin Inspection

The cooling fins are of the utmost importance to the cooling system, since they provide a means of transferring the cylinder heat to the air. Their condition can mean the difference between adequate or inadequate cylinder cooling. The fins are inspected at each regular inspection. Fin area is the total area (both sides of the fin) exposed to the air. During the inspection, the fins should be examined for cracks and breaks. [Figure 8] Small cracks are not a reason for cylinder removal. These cracks can be filled or even sometimes stop-drilled to prevent any further cracking. Rough or sharp corners on fins can be smoothed out by filing, and this action eliminates a possible source of new cracks. However, before reprofiling cylinder cooling fins, consult the manufacturer’s service or overhaul manual for the allowable limits.

|

| Figure 8. A cylinder head and fins |

The definition of fin area becomes important in the examination of fins for broken areas. It is a determining factor for cylinder acceptance or removal. For example, on a certain engine, if more than 12 inches in length of any one fin, as measured at its base, is completely broken off, or if the total fins broken on any one cylinder head exceed 83 square inches of area, the cylinder is removed and replaced. The reason for removal in this case is that an area of that size would cause a hot spot on the cylinder; since very little heat transfer could occur.

Where adjacent fins are broken in the same area, the total length of breakage permissible is six inches on any two adjacent fins, four inches on any three adjacent fins, two inches on any four adjacent fins, and one inch on any five adjacent fins. If the breakage length in adjacent fins exceeds this prescribed amount, the cylinder should be removed and replaced. These breakage specifications are applicable only to the engine used in this discussion as a typical example. In each specific case, applicable manufacturer’s instructions should be consulted.

Cylinder Baffle and Deflector System Inspection

Reciprocating engines use some type of intercylinder and cylinder head baffles to force the cooling air into close contact with all parts of the cylinders. Figure 2 shows a baffle and deflector system around a cylinder. The air baffle blocks the flow of air and forces it to circulate between the cylinder and the deflectors. Figure 9 illustrates a baffle and deflector arrangement designed to cool the cylinder head. The air baffle prevents the air from passing away from the cylinder head and forces it to go between the head and deflector. Although the resistance offered by baffles to the passage of the cooling air demands that an appreciable pressure differential be maintained across the engine to obtain the necessary airflow, the volume of cooling air required is greatly reduced by employing properly designed and located cylinder deflectors.

|

| Figure 9. Cylinder head baffle and deflector system |

As shown in Figure 7, the airflow approaches the nacelle and piles up at the top of the engine, creating a high pressure in the top of the cylinders. This piling up of the air reduces the air velocity. The outlet at the bottom rear of the cowling produces a low-pressure area. As the air nears the cowl exit, it is speeded up again and merges smoothly with the airstream. The pressure differential between the top and the bottom of the engine forces the air past the cylinders through the passages formed by the deflectors. The baffles and deflectors normally are inspected during the regular engine inspection, but they should be checked whenever the cowling is removed for any purpose. Checks should be made for cracks, dents, or loose hold down studs. Cracks or dents, if severe enough, would necessitate repair or removal and replacement of these units. However, a crack that has just started can be stop-drilled, and dents can be straightened, permitting further service from these baffles and deflectors.

[ad-longest]

Cylinder Temperature Indicating Systems

This system usually consists of an indicator, electrical wiring, and a thermocouple. The wiring is between the instrument and the nacelle firewall. At the firewall, one end of the thermocouple leads connects to the electrical wiring, and the other end of the thermocouple leads connects to the cylinder. The thermocouple consists of two dissimilar metals, generally constantan and iron, connected by wiring to an indicating system. If the temperature of the junction is different from the temperature where the dissimilar metals are connected to wires, a voltage is produced. This voltage sends a current through wires to the indicator, a current-measuring instrument graduated in degrees.

The thermocouple end that connects to the cylinder is either the bayonet or gasket type. To install the bayonet type, the knurled nut is pushed down and turned clockwise until it is snug. [Figure 10]

|

| Figure 10. Bayonet type CHT probe |

In removing this type, the nut is pushed down and turned counterclockwise until released. The gasket type fits under the spark plug and replaces the normal spark plug gasket. [Figure 11]

|

| Figure 11. Gasket type CHT probe |

When installing a thermocouple lead, remember not to cut off the lead because it is too long, but coil and tie up the excess length. The thermocouple is designed to produce a given amount of resistance. If the length of the lead is reduced, an incorrect temperature reading results. The bayonet or gasket of the thermocouple is inserted or installed on the hottest cylinder of the engine, as determined in the block test. When the thermocouple is installed and the wiring connected to the instrument, the indicated reading is the cylinder temperature. Prior to operating the engine, provided it is at ambient temperature, the cylinder head temperature indicator indicates the free outside air temperature; that is one test for determining that the instrument is working correctly. The cover glass of the cylinder head temperature indicator should be checked regularly to see that it has not slipped or cracked. The cover glass should be checked for indications of missing or damaged decals that indicate temperature limitations. If the thermocouple leads were excessive in length and had to be coiled and tied down, the tie should be inspected for security or chafing of the wire. The bayonet or gasket should be inspected for cleanness and security of mounting. When operating the engine, all of the electrical connections should be checked if the cylinder head temperature pointer fluctuates.

Exhaust Gas Temperature Indicating Systems

The exhaust gas temperature indicator consists of a thermocouple placed in the exhaust stream just after the cylinder port. [Figure 12] It is then connected to the instrument in the instrument panel. This allows for the adjustment of the mixture, which has a large effect on engine temperature. By using this instrument to set the mixture, the engine temperature can be controlled and monitored.

|

| Figure 12. EGT probe in exhaust stack |