The burning process in a gas turbine engine is continuous, and nearly all of the cooling air must be passed through the inside of the engine. If only enough air were admitted to the engine to provide an ideal air/fuel ratio of 15:1, internal temperatures would increase to more than 4,000 °F. In practice, a large amount of air in excess of the ideal ratio is admitted to the engine. The large surplus of air cools the hot sections of the engine to acceptable temperatures ranging from 1,500° to 2,100 °F. Because of the effect of cooling, the temperatures of the outside of the case are considerably less than those encountered within the engine. The hottest area occurs in and around the turbines. Although the gases have begun to cool a little at this point, the conductivity of the metal in the case carries the heat directly to the outside skin.

The secondary air passing through the engine cools the combustion-chamber liners. The liners are constructed to induce a thin, fast-moving film of air over both the inner and outer surfaces of the liner. Can-annular-type burners frequently are provided with a center tube to lead cooling air into the center of the burner to promote high combustion-efficiency and rapid dilution of the hot combustion gases while minimizing pressure losses. In all types of gas turbines, large amounts of relatively cool air join and mix with the burned gases aft of the burners to cool the hot gases just before they enter the turbines.

Cooling-air inlets are frequently provided around the exterior of the engine to permit the entrance of air to cool the turbine case, the bearings, and the turbine nozzle. Internal air is bled from the engine compressor section and is vented to the bearings and other parts of the engine. Air vented into or from the engine is ejected into the exhaust stream. When located on the side of the engine, the case is cooled by outside air flowing around it. The engine exterior and the engine nacelle are cooled by passing fan air around the engine and the nacelle. The engine compartment frequently is divided into two sections. The forward section is referred to as the cold section and the aft section (turbine) is referred to as the hot section. Case drains drain almost potential leaks overboard to prevent fluids from building up in the nacelle.

Accessory Zone Cooling

Turbine powerplants can be divided into primary zones that are isolated from each other by fireproof bulkheads and seals. The zones are the fan case compartment, intermediate compressor case compartment, and the core engine compartment. [Figure 1] Calibrated airflows are supplied to the zones to keep the temperatures around the engine at levels that are acceptable. The airflow provides for proper ventilation to prevent a buildup of any harmful vapors. Zone 1, for example, is around the fan case that contains the accessory case and the electronic engine control (EEC). This area is vented by using ram air through an inlet in the nose cowl and is exhausted through a louvered vent in the right fan cowling. |

| Figure 1. Accessory zone cooling |

If the pressure exceeds a certain limit, a pressure relief door opens and relieves the pressure. Zone 2 is cooled by fan air from the upper part of the fan duct and is exhausted at the lower end back into the fan air stream. This area has both fuel and oil lines, so removing any unwanted vapors would be important.

Zone 3 is the area around the high-pressure compressor to the turbine cases. This zone also contains fuel and oil lines and other accessories. Air enters from the exhaust of the precooler and other areas and is exhausted from the zone through the aft edge of the thrust reverser inner wall and the turbine exhaust sleeve.

Zone 3 is the area around the high-pressure compressor to the turbine cases. This zone also contains fuel and oil lines and other accessories. Air enters from the exhaust of the precooler and other areas and is exhausted from the zone through the aft edge of the thrust reverser inner wall and the turbine exhaust sleeve.

Turbine Engine Insulation Blankets

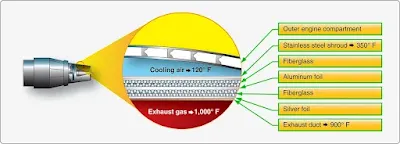

To reduce the temperature of the structure in the vicinity of the exhaust duct or thrust augmentor (afterburner) and to eliminate the possibility of fuel or oil coming in contact with the hot parts of the engine, it is sometimes necessary to provide insulation on the exhaust duct of gas turbine engines. The exhaust duct surface temperature runs quite high. A typical insulation blanket and the temperatures obtained at various locations are shown in Figure 2. This blanket contains fiberglass as the low conductance material and aluminum foil as the radiation shield. The blanket is suitably covered so that it does not become oil soaked. Insulation blankets have been used rather extensively on many installations in which long exhaust is needed. Some auxiliary power units (APU) mounted in the tail cone of transport aircraft have air that surrounds the exhaust tail pipe that provides cooling and protects the surrounding structure. |

| Figure 2. Typical engine insulation blanket |