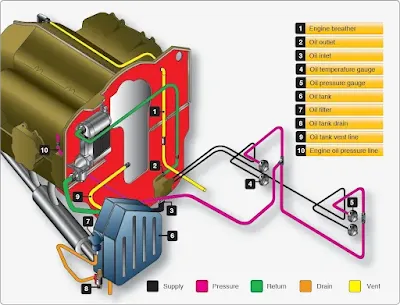

Oil Tank

The oil tank, constructed of welded aluminum, is serviced (filled) through a filler neck located on the tank and equipped with a spring-loaded locking cap. Inside the tank, a weighted, flexible rubber oil hose is mounted so that it is repositioned automatically to ensure oil pickup during all maneuvers. A dipstick guard is welded inside the tank for the protection of the flexible oil hose assembly. During normal flight, the oil tank is vented to the engine crankcase by a flexible line at the top of the tank. The location of the oil system components in relation to each other and to the engine is shown in Figure 1.

|

| Figure 1. Oil system perspective |

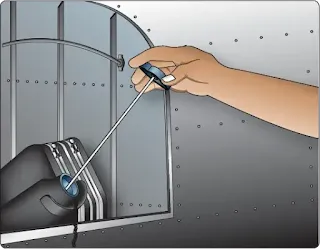

Repair of an oil tank usually requires that the tank be removed. The removal and installation procedures normally remain the same regardless of whether the engine is removed or not. First, the oil must be drained. Most light aircraft provide an oil drain similar to that shown in Figure 2.

|

| Figure 2. Oil tank drain |

On some aircraft, the normal ground attitude of the aircraft may prevent the oil tank from draining completely. If the amount of undrained oil is excessive, the aft portion of the tank can be raised slightly after the tank straps have been loosened to complete the drainage.

After disconnecting the oil inlet and vent lines, the scupper drain hose and bonding wire can be removed. [Figure 3] The securing straps fitted around the tank can now be removed. [Figure 4] Any safety wire securing the clamp must be removed before the clamp can be loosened and the strap disconnected. The tank can now be lifted out of the aircraft. The tank is reinstalled by reversing the sequence used in the tank removal. After installation, the oil tank should be filled to capacity. [Figure 5]

|

| Figure 3. Disconnect oil lines |

|

| Figure 4. Removal of securing straps |

|

| Figure 5. Filling an oil tank |

After the oil tank has been filled, the engine should be run for at least two minutes. Then, the oil level should be checked and, if necessary, sufficient oil should be added to bring the oil up to the proper level on the dipstick. [Figure 6]

|

| Figure 6. Checking oil level with dipstick |

Oil Cooler

The oil cooler used with this aircraft’s opposed-type engine is the honeycomb type. [Figure 7] With the engine operating and an oil temperature below 65 °C (150 °F), oil cooler bypass valve opens allowing oil to bypass the core. This valve begins to close when the oil temperature reaches approximately 65 °C (150 °F). When the oil temperature reaches 85 °C (185 °F), ±2 °C, the valve is closed completely, diverting all oil flow through the cooler core.

|

| Figure 7. Oil cooler |

Oil Temperature Bulbs

Most oil temperature bulbs are mounted in the pressure oil screen housing. They relay an indication of engine oil inlet temperature to the oil temperature indicators mounted on the instrument panel. Temperature bulbs can be replaced by removing the safety wire and disconnecting the wire leads from the temperature bulbs, then removing the temperature bulbs using the proper wrench. [Figure 8]

|

| Figure 8. Removing oil temperature bulb |

Pressure and Scavenge Oil Screens

Sludge accumulates on the pressure and scavenges oil screens during engine operation. [Figure 9] These screens must be removed, inspected, and cleaned at the intervals specified by the manufacturer.

|

| Figure 9. Oil pressure screen (A) and scavenge oil screen assembly (B) |

Typical removal procedures include removing the safety devices and loosening the oil screen housing or cover plate. A suitable container should be provided to collect the oil that drains from the filter housing or cavity. The container must be clean so that the oil collected in it can be examined for foreign particles. Any contamination already present in the container gives a false indication of the engine condition. This could result in a premature engine removal.

After the screens are removed, they should be inspected for contamination and for the presence of metal particles that may indicate possible engine internal wear, damage, or in extreme cases, engine failure. The screen must be cleaned prior to reinstalling in the engine. In some cases, it is necessary to disassemble the filter for inspection and cleaning. The manufacturer’s procedures should be followed when disassembling and reassembling an oil screen assembly. When reinstalling a filter or screen, use new O-rings and gaskets and tighten the filter housing or cover retaining nuts to the torque value specified in the applicable maintenance manual. Filters should be safetied as required.

[ad-mid]

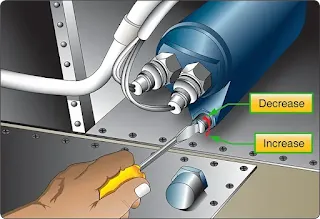

Oil Pressure Relief Valve

An oil pressure regulating (relief) valve limits oil pressure to the value specified by the engine manufacturer. Oil pressure settings can vary from around 35 psi minimum to around 90 psi maximum, depending on the installation. The oil pressure must be high enough to ensure adequate lubrication of the engine and accessories at high speeds and power settings. On the other hand, the pressure must not be too high, since leakage and damage to the oil system may result. Before any attempt is made to adjust the oil pressure, the engine must be at the correct operating temperature and a check should be made to assure that the correct viscosity oil is being used in the engine. One example of adjusting the oil pressure is done by removing a cover nut, loosening a locknut, and turning the adjusting screw. [Figure 10] Turn the adjusting screw clockwise to increase the pressure, or counterclockwise to decrease the pressure. Make the pressure adjustments while the engine is idling and tighten the adjustment screw lock-nut after each adjustment. Check the oil pressure reading while the engine is running at the rpm specified in the manufacturer’s maintenance manual. This may be from around 1,900 rpm to 2,300 rpm. The oil pressure reading should be between the limits prescribed by the manufacturer at all throttle settings.

|

| Figure 10. Oil pressure relief valve adjustment |

RELATED POSTS