There are several forces acting on the propeller as it turns; a major one is centrifugal force. This force at high rpm tends to pull the blades out of the hub, so blade weight is very important to the design of a propeller. Excessive blade tip speed (rotating the propeller too fast) may result not only in poor blade efficiency, but also in fluttering and vibration. Since the propeller speed is limited, the aircraft speed of a propeller driven aircraft is also limited—to approximately 400 miles per hour (mph). As aircraft speeds increased, turbofan engines were used for higher speed aircraft. Propeller-driven aircraft have several advantages and are widely used for applications in turboprops and reciprocating engine installations. Takeoff and landing can be shorter and less expensive. New blade materials and manufacturing techniques have increased the efficiency of propellers. Many smaller aircraft will continue to use propellers well into the future.

|

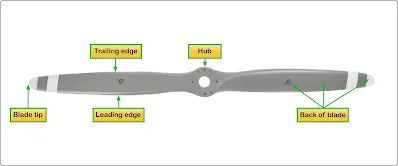

| Figure 1. Basic nomenclature of propellers |

|

| Figure 2. Cross-sectional area of a propeller blade airfoil |

The basic nomenclature of the parts of a propeller is shown in Figure 1 for a simple fixed-pitch, two-bladed wood propeller. The aerodynamic cross-section of a blade in Figure 2 includes terminology to describe certain areas shown.

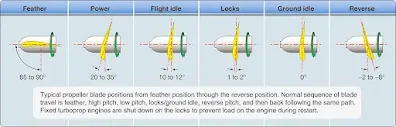

The many different types of propeller systems have been developed for specific aircraft installation, speed, and mission. Propeller development has encouraged many propellers were fabric-covered sticks made to force air in a rearward direction. Propellers started as simple two bladed wood propellers and have advanced to the complex propulsion systems of turboprop aircraft that involve more than just the propeller. As an outgrowth of operating large, more complex propellers, a variable-pitch, constant-speed feathering and reversing propeller system was developed. This system allows the engine rpm to be varied only slightly during different flight conditions and, therefore, increases flying efficiency. A basic constant-speed system consists of a flyweight-equipped governor unit that controls the pitch angle of the blades so that the engine speed remains constant. The governor can be regulated by controls in the cockpit so that any desired blade angle setting and engine operating speed can be obtained. A low-pitch, high-rpm setting, for example, can be utilized for takeoff. Then, after the aircraft is airborne, a higher pitch and lower rpm setting can be used. Figure 3 shows normal propeller movement with the positions of low pitch, high pitch, feather (used if the engine quits to reduce drag), and zero pitch into negative pitch, or reverse pitch.

|

| Figure 3. Propeller range positions |

Basic Propeller Principles

The aircraft propeller consists of two or more blades and a central hub to which the blades are attached. Each blade of an aircraft propeller is essentially a rotating wing. As a result of their construction, the propeller blades produce forces that create thrust to pull or push the airplane through the air. The power needed to rotate the propeller blades is furnished by the engine. The propeller is mounted on a shaft, which may be an extension of the crankshaft on low-horsepower engines; on high-horsepower engines, it is mounted on a propeller shaft that is geared to the engine crankshaft. In either case, the engine rotates the airfoils of the blades through the air at high speeds, and the propeller transforms the rotary power of the engine into thrust.