When the engine output power is increased, the power turbines tend to increase speed. The flyweights in the CSU sense this acceleration and the flyweights go into an overspeed condition because of the increase centrifugal force. This force causes the control valve to move up and restrict oil flow to the propeller dome. [Figure 2] The feathering spring increases the propeller pitch to maintain the selected speed. Reducing power causes an under-speed of the flyweights, downward movement of the control valve, more oil in propeller dome, resulting in a lower pitch to control propeller speed. The propeller governor houses an electro-magnetic coil, which is used to match the rpm of both propellers during cruise. An aircraft supplied synchrophaser unit controls this function.

As the blades move to reverse, the dome pulls the slip ring forward and moves the beta valve outward, restricting the oil flow. This stops the blade movement toward reverse. To obtain more reverse thrust, move the power lever back more to reset the beta valve inward, and repeat the process. Move the reset arm on the CSU rearward by the interconnecting rod at the same time the blade angle moves toward reverse. This causes the reset lever and reset post to move down in the CSU, bringing the reset lever closer to the speeder spring cup. As propeller speed increases due to the increase in engine power, the governor flyweights begin to move outwards. Since the reset lever is closer to the speeder spring cup, the cup contacts the reset lever before the flyweights would normally reach the on-speed position (95 percent propeller speed instead of 100 percent). As the reset lever is pushed up by the flyweights/ speeder spring cup, the Py air bleeds from the fuel control unit (FCU) which lowers the fuel flow, engine power, and thus propeller speed. In reverse, propeller speed remains 5 percent below the selected propeller speed so that the control valve remains fully open, and only the beta valve controls the oil flow to the propeller dome.

[ad-mid]

At low power, the propeller and governor flyweights do not turn fast enough to compress the speeder spring. [Figure 3] In this condition, the control valve moves down and high pressure oil pushes the dome forward moving the blades towards low pitch. Any further movement pulls the beta rod and slip ring forward. The forward motion of the slip ring is transmitted to the beta valve via the beta lever and the carbon block. Forward movement of the beta valve stops the oil supply to the propeller. This prevents the blade angles from going any lower. This is the primary blade angle (PBA) and is the minimum blade angle allowed for flight operation. From this point, the propeller is in the beta mode. If the engine power is reduced when the propeller is at the primary blade angle, the propeller speed decreases since the blade angle does not change.

The lock-pitch solenoid valve prevents the propeller from going into reverse or below the primary blade angle in the event of a beta system malfunction in flight. The solenoid is energized by a switch (airframe supplied) mechanically connected to the propeller slip-ring linkage via a second carbon block. As oil pressure leaks off around the propeller shaft oil transfer sleeve, the blade angle slowly drifts back toward high pitch. This deactivates the low pitch solenoid valve and restores the oil supply to the propeller servo. The low pitch solenoid valve cycles (close/open) as backup to the beta valve function. Moving the power lever backwards causes the reversing cam and cable to move the beta valve backward, allowing more oil to flow into the propeller dome, and causing the blades to go towards reverse pitch. [Figure 4]

In this mode, the propeller speed is no longer controlled by changing the blade angle. It is now controlled by limiting engine power. Bringing the propeller lever to the feather position causes the speed selection lever on the CSU to push the feathering valve plunger and allows propeller servo oil to dump into the reduction gearbox sump. The pressure loss in the propeller hub causes the feathering spring and the propeller counterweights to feather the propeller. In the event of a propeller overspeed not controlled by the propeller overspeed governor (oil governor), the flyweights in the propeller governor move outward until the speeder spring cup contacts the reset lever. [Figure 5] The movement of the reset lever around its pivot point opens the Py air passage. Py bleeds into the reduction gearbox limiting the fuel supply to the engine. This prevents the propeller/power turbines from accelerating beyond 106 percent rpm.

RELATED POSTS

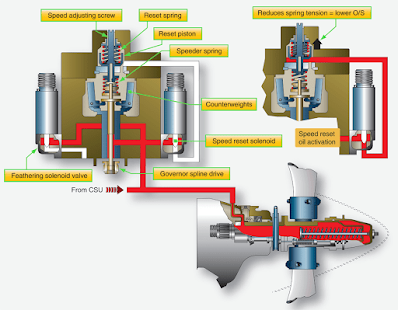

The oil overspeed governor houses a set of flyweights connected to a control valve that is driven by a beveled gear mounted on the propeller shaft. [Figure 6] The flyweight’s centrifugal force is acting against two springs: a speeder spring and a reset spring. When the propeller speed reaches a specified limit (4 percent over maximum propeller speed), the governor flyweights lift the control valve and bleed off propeller servo oil into the reduction gearbox sump, causing the blade angle to increase. An increase in blade pitch puts more load on the engine and slows down the propeller. To test the unit, the speed reset solenoid is activated and servo oil pressure pushes against the reset piston to cancel the effect of the reset spring. With less spring tension acting on the flyweights, the overspeed governor can be tested at speeds lower than maximum.

On twin installation, a second solenoid valve is mounted on the overspeed governor and is used in conjunction with the aircraft autofeather system. The system is switched on for takeoff and, in the event of an engine malfunction, energizes the solenoid valve to dump propeller servo oil into the reduction gearbox sump. The feathering spring and propeller counterweights move the blade quickly to feather.