Work = Thrust × Distance

The power expended by thrust is equal to the thrust times the velocity at which it moves the airplane.

Power = Thrust × Velocity

If the power is measured in horsepower units, the power expended by the thrust is termed thrust horsepower.

The engine supplies brake horsepower through a rotating shaft, and the propeller converts it into thrust horsepower. In this conversion, some power is wasted. For maximum efficiency, the propeller must be designed to keep this waste as small as possible. Since the efficiency of any machine is the ratio of the useful power output to the power input, propeller efficiency is the ratio of thrust horsepower to brake horsepower. The usual symbol for propeller efficiency is the Greek letter η (eta). Propeller efficiency varies from 50 percent to 87 percent, depending on how much the propeller slips.

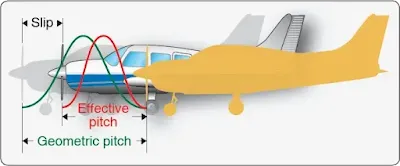

Pitch is not the same as blade angle, but because pitch is largely determined by blade angle, the two terms are often used interchangeably. An increase or decrease in one is usually associated with an increase or decrease in the other. Propeller slip is the difference between the geometric pitch of the propeller and its effective pitch. [Figure 1]

Geometric pitch is the distance a propeller should advance in one revolution with no slippage; effective pitch is the distance it actually advances. Thus, geometric or theoretical pitch is based on no slippage. Actual, or effective, pitch recognizes propeller slippage in the air. The relationship can be shown as:

Geometric pitch – Effective pitch = slip

Geometric pitch is usually expressed in pitch inches and calculated by using the following formula:

|

| Figure 1. Effective pitch and geometric pitch |

Geometric pitch – Effective pitch = slip

Geometric pitch is usually expressed in pitch inches and calculated by using the following formula:

GP = 2 × π R × tangent of blade angle at 75 percent station

R = Radius at the 75 percent blade station

π = 3.14

R = Radius at the 75 percent blade station

π = 3.14

[ad-mid]

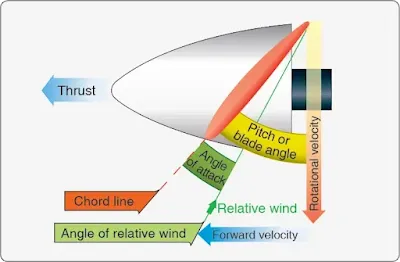

Although blade angle and propeller pitch are closely related, blade angle is the angle between the face or chord of a blade section and the plane in which the propeller rotates. [Figure 2] Blade angle, usually measured in degrees, is the angle between the chordline of the blade and the plane of rotation. The chordline of the propeller blade is determined in about the same manner as the chordline of an airfoil. In fact, a propeller blade can be considered as being composed of an infinite number of thin blade elements, each of which is a miniature airfoil section whose chord is the width of the propeller blade at that section. Because most propellers have a flat blade face, the chord line is often drawn along the face of the propeller blade.

Centrifugal force is a physical force that tends to throw the rotating propeller blades away from the hub. [Figure 5A] This is the most dominant force on the propeller. Torque bending force, in the form of air resistance, tends to bend the propeller blades in the direction opposite that of rotation. [Figure 5B] Thrust bending force is the thrust load that tends to bend propeller blades forward as the aircraft is pulled through the air. [Figure 5C] Aerodynamic twisting force tends to turn the blades to a high blade angle. [Figure 5D] Centrifugal twisting force, being greater than the aerodynamic twisting force, tends to force the blades toward a low blade angle.

At least two of these forces acting on the propellers blades are used to move the blades on a controllable pitch propeller. Centrifugal twisting force is sometimes used to move the blades to the low pitch position, while aerodynamic twisting force is used to move the blades into high pitch. These forces can be the primary or secondary forces that move the blades to the new pitch position.

|

| Figure 2. Propeller aerodynamic factors |

The typical propeller blade can be described as a twisted airfoil of irregular planform. Two views of a propeller blade are shown in Figure 3. For purposes of analysis, a blade can be divided into segments that are located by station numbers in inches from the center of the blade hub. The cross-sections of each 6-inch blade segment are shown as airfoils in the right side of Figure 3. Also identified in Figure 3 are the blade shank and the blade butt. The blade shank is the thick, rounded portion of the propeller blade near the hub and is designed to give strength to the blade. The blade butt, also called the blade base or root, is the end of the blade that fits in the propeller hub. The blade tip is that part of the propeller blade farthest from the hub, generally defined as the last 6 inches of the blade.

|

| Figure 3. Typical propeller blade elements |

A cross-section of a typical propeller blade is shown in Figure 4. This section or blade element is an airfoil comparable to a cross-section of an aircraft wing. The blade back is the cambered or curved side of the blade, similar to the upper surface of an aircraft wing. The blade face is the flat side of the propeller blade. The chord line is an imaginary line drawn through the blade from the leading edge to the trailing edge. The leading edge is the thick edge of the blade that meets the air as the propeller rotates.

|

| Figure 4. Cross-section of a propeller blade |

A rotating propeller is acted upon by centrifugal twisting, aerodynamic twisting, torque bending, and thrust bending forces. The principal forces acting on a rotating propeller are illustrated in Figure 5.

|

| Figure 5. Forces acting on a rotating propeller |

At least two of these forces acting on the propellers blades are used to move the blades on a controllable pitch propeller. Centrifugal twisting force is sometimes used to move the blades to the low pitch position, while aerodynamic twisting force is used to move the blades into high pitch. These forces can be the primary or secondary forces that move the blades to the new pitch position.

A propeller must be capable of withstanding severe stresses, which are greater near the hub, caused by centrifugal force and thrust. The stresses increase in proportion to the rpm. The blade face is also subjected to tension from the centrifugal force and additional tension from the bending. For these reasons, nicks or scratches on the blade may cause very serious consequences. These could lead to cracks and failure of the blade.

A propeller must also be rigid enough to prevent fluttering, a type of vibration in which the ends of the blade twist back and forth at high frequency around an axis perpendicular to the engine crankshaft. Fluttering is accompanied by a distinctive noise, often mistaken for exhaust noise. The constant vibration tends to weaken the blade and eventually causes failure.

[ad-long]

Aerodynamic Factors

To understand the action of a propeller, consider first its motion, which is both rotational and forward. Thus, as shown by the vectors of propeller forces in Figure 6, a section of a propeller blade moves downward and forward. As far as the forces are concerned, the result is the same as if the blade were stationary and the air coming at it from a direction opposite its path. The angle at which this air (relative wind) strikes the propeller blade is called angle of attack (AOA). The air deflection produced by this angle causes the dynamic pressure at the engine side of the propeller blade to be greater than atmospheric pressure, creating thrust. |

| Figure 6. Propeller forces |

Another way to consider thrust is in terms of the mass of air handled. In these terms, thrust is equal to the mass of air handled multiplied by the slipstream velocity minus the velocity of the airplane. Thus, the power expended in producing thrust depends on the mass of air moved per second. On the average, thrust constitutes approximately 80 percent of the torque (total horsepower absorbed by the propeller). The other 20 percent is lost in friction and slippage. For any speed of rotation, the horsepower absorbed by the propeller balances the horsepower delivered by the engine. For any single revolution of the propeller, the amount of air displaced (moved) depends on the blade angle, which determines the quantity or amount of mass of air the propeller moves. Thus, the blade angle is an excellent means of adjusting the load on the propeller to control the engine rpm. If the blade angle is increased, more load is placed on the engine, tending to slow it down unless more power is applied. As an airfoil is moved through the air, it produces two forces: lift and drag. Increasing propeller blade angle increases the AOA and produces more lift and drag; this action increases the horsepower required to turn the propeller at a given rpm. Since the engine is still producing the same horsepower, the propeller slows down. If the blade angle is decreased, the propeller speeds up. Thus, the engine rpm can be controlled by increasing or decreasing the blade angle.

The blade angle is also an excellent method of adjusting the AOA of the propeller. On constant-speed propellers, the blade angle must be adjusted to provide the most efficient AOA at all engine and airplane speeds. Lift versus drag curves, which are drawn for propellers as well as wings, indicate that the most efficient AOA is a small one varying from 2° to 4° positive. The actual blade angle necessary to maintain this small AOA varies with the forward speed of the airplane. This is due to a change in the relative wind direction, which varies with aircraft speed.

Fixed-pitch and ground-adjustable propellers are designed for best efficiency at one rotation and forward speed. In other words, they are designed to fit a given airplane and engine combination. A propeller may be used that provides the maximum propeller efficiency for takeoff, climb, cruising, or high speeds. Any change in these conditions results in lowering the efficiency of both the propeller and the engine. A constant-speed propeller, however, keeps the blade angle adjusted for maximum efficiency for most conditions encountered in flight. During takeoff, when maximum power and thrust are required, the constant-speed propeller is at a low propeller blade angle or pitch. The low blade angle keeps the AOA small and efficient with respect to the relative wind. At the same time, it allows the propeller to handle a smaller mass of air per revolution. This light load allows the engine to turn at high rpm and to convert the maximum amount of fuel into heat energy in a given time. The high rpm also creates maximum thrust. Although the mass of air handled per revolution is small, the engine rpm is high, the slipstream velocity (air coming off the propeller) is high, and, with the low airplane speed, the thrust is maximum.

The blade angle is also an excellent method of adjusting the AOA of the propeller. On constant-speed propellers, the blade angle must be adjusted to provide the most efficient AOA at all engine and airplane speeds. Lift versus drag curves, which are drawn for propellers as well as wings, indicate that the most efficient AOA is a small one varying from 2° to 4° positive. The actual blade angle necessary to maintain this small AOA varies with the forward speed of the airplane. This is due to a change in the relative wind direction, which varies with aircraft speed.

Fixed-pitch and ground-adjustable propellers are designed for best efficiency at one rotation and forward speed. In other words, they are designed to fit a given airplane and engine combination. A propeller may be used that provides the maximum propeller efficiency for takeoff, climb, cruising, or high speeds. Any change in these conditions results in lowering the efficiency of both the propeller and the engine. A constant-speed propeller, however, keeps the blade angle adjusted for maximum efficiency for most conditions encountered in flight. During takeoff, when maximum power and thrust are required, the constant-speed propeller is at a low propeller blade angle or pitch. The low blade angle keeps the AOA small and efficient with respect to the relative wind. At the same time, it allows the propeller to handle a smaller mass of air per revolution. This light load allows the engine to turn at high rpm and to convert the maximum amount of fuel into heat energy in a given time. The high rpm also creates maximum thrust. Although the mass of air handled per revolution is small, the engine rpm is high, the slipstream velocity (air coming off the propeller) is high, and, with the low airplane speed, the thrust is maximum.

After liftoff, as the speed of the airplane increases, the constant-speed propeller changes to a higher angle (or pitch). Again, the higher blade angle keeps the AOA small and efficient with respect to the relative wind. The higher blade angle increases the mass of air handled per revolution. This decreases the engine rpm, reducing fuel consumption and engine wear, and keeps thrust at a maximum.

For climb after takeoff, the power output of the engine is reduced to climb power by decreasing the manifold pressure and increasing the blade angle to lower the rpm. Thus, the torque (horsepower absorbed by the propeller) is reduced to match the reduced power of the engine. The AOA is again kept small by the increase in blade angle. The greater mass of air handled per second, in this case, is more than offset by the lower slipstream velocity and the increase in airspeed.

At cruising altitude, when the airplane is in level flight and less power is required than is used in takeoff or climb, engine power is again reduced by lowering the manifold pressure and increasing the blade angle to decrease the rpm. Again, this reduces torque to match the reduced engine power; for, although the mass of air handled per revolution is greater, it is more than offset by a decrease in slipstream velocity and an increase in airspeed. The AOA is still small because the blade angle has been increased with an increase in airspeed. Pitch distribution is the twist in the blade from the shank to the blade tip, due to the variation in speeds that each section of the blade is traveling. The tip of the blade is traveling much faster than the inner portion of the blade.

For climb after takeoff, the power output of the engine is reduced to climb power by decreasing the manifold pressure and increasing the blade angle to lower the rpm. Thus, the torque (horsepower absorbed by the propeller) is reduced to match the reduced power of the engine. The AOA is again kept small by the increase in blade angle. The greater mass of air handled per second, in this case, is more than offset by the lower slipstream velocity and the increase in airspeed.

At cruising altitude, when the airplane is in level flight and less power is required than is used in takeoff or climb, engine power is again reduced by lowering the manifold pressure and increasing the blade angle to decrease the rpm. Again, this reduces torque to match the reduced engine power; for, although the mass of air handled per revolution is greater, it is more than offset by a decrease in slipstream velocity and an increase in airspeed. The AOA is still small because the blade angle has been increased with an increase in airspeed. Pitch distribution is the twist in the blade from the shank to the blade tip, due to the variation in speeds that each section of the blade is traveling. The tip of the blade is traveling much faster than the inner portion of the blade.