The moving parts and dirty environment of the landing gear make this an area of regular maintenance. Because of the stresses and pressures acting on the landing gear, inspection, servicing, and other maintenance becomes a continuous process. The most important job in the maintenance of the aircraft landing gear system is thorough accurate inspections. To properly perform inspections, all surfaces should be cleaned to ensure that no trouble spots are undetected.

Periodically, it is necessary to inspect shock struts, trunnion and brace assemblies and bearings, shimmy dampers, wheels, wheel bearings, tires, and brakes. Landing gear position indicators, lights, and warning horns must also be checked for proper operation. During all inspections and visits to the wheel wells, ensure all ground safety locks are installed.

Other landing gear inspection items include checking emergency control handles and systems for proper position and condition. Inspect landing gear wheels for cleanliness, corrosion, and cracks. Check wheel tie bolts for looseness. Examine anti-skid wiring for deterioration. Check tires for wear, cuts, deterioration, presence of grease or oil, alignment of slippage marks, and proper inflation. Inspect landing gear mechanism for condition, operation, and proper adjustment. Lubricate the landing gear, including the nose wheel steering. Check steering system cables for wear, broken strands, alignment, and safetying. Inspect landing gear shock struts for such conditions as cracks, corrosion, breaks, and security. Where applicable, check brake clearances and wear.

Various types of lubricant are required to lubricate points of friction and wear on landing gear. Specific products to be used are given by the manufacturer in the maintenance manual. Lubrication may be accomplished by hand or with a grease gun. Follow manufacturer’s instructions. Before applying grease to a pressure grease fitting, be sure the fitting is wiped clean of dirt and debris, as well as old hardened grease. Dust and sand mixed with grease produce a very destructive abrasive compound. Wipe off all excess grease while greasing the gear. The piston rods of all exposed strut cylinders and actuating cylinders should be clean at all times.

Periodically, wheel bearings must be removed, cleaned, inspected, and lubricated. When cleaning a wheel bearing, use the recommended cleaning solvent. Do not use gasoline or jet fuel. Dry the bearing by directing a blast of dry air between the rollers. Do not direct the air so that it spins the bearing as without lubrication, this could cause the bearing to fly apart resulting in injury. When inspecting the bearing, check for defects that would render it unserviceable, such as cracks, flaking, broken bearing surfaces, roughness due to impact pressure or surface wear, corrosion or pitting, discoloration from excessive heat, cracked or broken bearing cages, and scored or loose bearing cups or cones that would affect proper seating on the axle or wheel. If any discrepancies are found, replace the bearing with a serviceable unit. Bearings should be lubricated immediately after cleaning and inspection to prevent corrosion.

To lubricate a tapered roller bearing, use a bearing lubrication tool or place a small amount of the approved grease on the palm of the hand. Grasp the bearing with the other hands and press the larger diameter side of the bearing into the grease to force it completely through the space between the bearing rollers and the cone. Gradually turn the bearing so that all of the rollers have been completely packed with grease. [Figure 1]

[ad-mid]Landing Gear Rigging and Adjustment

Occasionally, it becomes necessary to adjust the landing gear switches, doors, linkages, latches, and locks to ensure proper operation of the landing gear system and doors. When landing gear actuating cylinders are replaced and when length adjustments are made, over-travel must be checked. Over-travel is the action of the cylinder piston beyond the movement necessary for landing gear extension and retraction. The additional action operates the landing gear latch mechanisms.

A wide variety of aircraft types and landing gear system designs result in procedures for rigging and adjustment that vary from aircraft to aircraft. Uplock and downlock clearances, linkage adjustments, limit switch adjustments, and other adjustments must be confirmed by the technician in the manufacturer’s maintenance data before taking action. The following examples of various adjustments are given to convey concepts, rather than actual procedures for any particular aircraft.

Adjusting Landing Gear Latches

The adjustment of various latches is a primary concern to the aircraft technician. Latches are generally used in landing gear systems to hold the gear up or down and/or to hold the gear doors open or closed. Despite numerous variations, all latches are designed to do the same thing. They must operate automatically at the proper time, and they must hold the unit in the desired position. A typical landing gear door latch is examined below. Many gear up latches operate similarly. Clearances and dimensional measurements of rollers, shafts, bushings, pins, bolts, etc., are common.

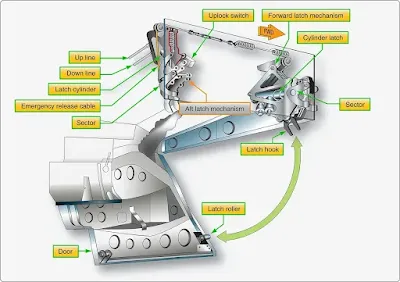

On this particular aircraft, the landing gear door is held closed by two latches. To have the door locked securely, both latches must grip and hold the door tightly against the aircraft structure. The principle components of each latch mechanism are shown in Figure 2. They are a hydraulic latch cylinder, a latch hook, a spring loaded crank-and-lever linkage with sector, and the latch hook.

|

| Figure 2. An example of a main landing gear door latch mechanism |

When hydraulic pressure is applied, the cylinder operates the linkage to engage (or disengage) the hook with (or from) the roller on the gear door. In the gear-down sequence, the hook is disengaged by the spring load on the linkage. In the gear-up sequence, when the closing door is in contact with the latch hook, the cylinder operates the linkage to engage the latch hook with the door roller. Cables on the landing gear emergency extension system are connected to the sector to permit emergency release of the latch rollers. An uplock switch is installed on, and actuated by, each latch to provide a gear up indication in the flight deck. With the gear up and the door latched, inspect the latch roller for proper clearance as shown in Figure 3-A. On this installation, the required clearance is 1/8 ± 3/32-inch. If the roller is not within tolerance, it may be adjusted by loosening its mounting bolts and raising or lowering the latch roller support. This is accomplished via the elongated holes and serrated locking surfaces of the latch roller support and serrated plate. [Figure 3-B]

|

| Figure 3. Main landing gear door latch roller clearance measurement and adjustment |

Gear Door Clearances

Landing gear doors have specific allowable clearances between the doors and the aircraft structure that must be maintained. Adjustments are typically made at the hinge installations or to the connecting links that support and move the door. On some installations, door hinges are adjusted by placing a serrated hinge with an elongated mounting hole in the proper position in a hinge support fitting. Using serrated washers, the mounting bolt is torqued to hold the position. Figure 4 illustrates this type of mounting, which allows linear adjustments via the elongated hole.

|

| Figure 4. An adjustable door hinge installation for setting door clearance |

The distance landing gear doors open or close may depend upon the length of the door linkage. Rod end adjustments are common to fit the door. Adjustments to door stops are also a possibility. The manufacturer’s maintenance manual specifies the length of the linkages and gives procedure for adjusting the stops. Follow all specified procedures that are accomplished with the aircraft on jacks and the gear retracted. Doors that are too tight can cause structural damage. Doors that are too loose catch wind in flight, which could cause wear and potential failure, as well as parasite drag.

[ad-long]Drag and Side Brace Adjustment

Each landing gear has specific adjustments and tolerances per the manufacturer that permit the gear to function as intended. A common geometry used to lock a landing gear in the down position involves a collapsible side brace that is extended and held in an over-center position through the use of a locking link. Springs and actuators may also contribute to the motion of the linkage. Adjustments and tests are needed to ensure proper operation.

Figure 5 illustrates a landing gear on a small aircraft with such a side brace. It consists of an upper and lower link hinged at the center that permits the brace to jackknife during retraction of the gear. The upper end pivots on a trunnion attached to structure in the wheel well overhead. The lower end is attached to the shock strut. A locking link is incorporated between the upper end of the shock strut and the lower drag link. It is adjustable to provide the correct amount of over-center travel of the side brace links. This locks the gear securely in the down position to prevent collapse of the gear.

|

| Figure 5. Over-center adjustments on a small aircraft main gear |

To adjust the over-center position of the side brace locking link, the aircraft must be placed on jacks. With the landing gear in the down position, the lock link end fitting is adjusted so that the side brace links are held firmly over-center. When the gear is held inboard six inches from the down and locked position and then released, the gear must free fall into the locked down position.

In addition to the amount the side brace links are adjusted to travel over center, down lock spring tension must also be checked. This is accomplished with a spring scale. The tension on this particular gear is between 40 and 60 pounds. Check the manufacturer’s maintenance data for each aircraft to ensure correct tensions exist and proper adjustments are made.

Landing Gear Retraction Test

The proper functioning of a landing gear system and components can be checked by performing a landing gear retraction test. This is also known as swinging the gear. The aircraft is properly supported on jacks for this check, and the landing gear should be cleaned and lubricated if needed. The gear is then raised and lowered as though the aircraft were in flight while a close visual inspection is performed. All parts of the system should be observed for security and proper operation. The emergency back-up extension system should be checked whenever swinging the gear.

Retraction tests are performed at various times, such as during annual inspection. Any time a landing gear component is replaced that could affect the correct functioning of the landing gear system, a retraction test should follow when adjustments to landing gear linkages or components that affect gear system performance are made. It may be necessary to swing the gear after a hard or overweight landing. It is also common to swing the gear while attempting to locate a malfunction within the system. For all required retraction tests and the specific inspection points to check, consult the manufacturer’s maintenance manual for the aircraft in question as each landing gear system is unique.

The following is a list of general inspection items to be performed while swinging the gear:

- Check the landing gear for proper extension and retraction.

- Check all switches, lights, and warning devices for proper operation.

- Check the landing gear doors for clearance and freedom from binding.

- Check landing gear linkage for proper operation, adjustment, and general condition.

- Check the alternate/emergency extension or retraction systems for proper operation.

- Investigate any unusual sounds, such as those caused by rubbing, binding, chafing, or vibration.