Carbon Fouling of Spark Plugs

Carbon fouling from fuel is associated with mixtures that are too rich to burn or mixtures that are so lean they cause intermittent firing. [Figure 1]

|

| Figure 1. Carbon fouled spark plug |

Each time a spark plug does not fire, raw fuel and oil collect on the nonfiring electrodes and nose insulator. These difficulties are almost invariably associated with an improper idle mixture adjustment, a leaking primer, or carburetor malfunctions that cause too rich a mixture in the idle range. A rich fuel-air mixture is detected by soot or black smoke coming from the exhaust and by an increase in rpm when the idling fuel-air mixture is leaned to best power. The soot that forms as a result of overly richidle fuel-air mixtures settles on the inside of the combustion chamber because the heat of the engine and the turbulence in the combustion chamber are slight. At higher engine speeds and powers, however, the soot is swept out and does not condense out of the charge in the combustion chamber.

Oil Fouling of Spark Plugs

Even though the idling fuel-air mixture is correct, there is a tendency for oil to be drawn into the cylinder past the piston rings, valve guides, and impeller shaft oil seal rings. At low engine speeds, the oil combines with the soot in the cylinder to form a solid that is capable of shorting out the spark plug. Spark plugs that are wet or covered with lubricating oil are usually grounded out during the engine start. In some cases, these plugs may clear up and operate properly after a short period of engine operation.

Engine oil that has been in service for any length of time holds in suspension minute carbon particles that are capable of conducting an electric current. Thus, a spark plug will not arc the gap between the electrodes when the plug is full of oil. Instead, the high-voltage impulse flows through the oil from one electrode to the other without a spark as though a wire conductor were placed between the two electrodes. Combustion in the affected cylinder does not occur until, at a higher rpm, increased airflow has carried away the excess oil. Then, when intermittent firing starts, combustion assists in emitting the remaining oil. In a few seconds, the engine is running clean with white fumes of evaporating and burning oil coming from the exhaust.

[ad-mid]

Lead Fouling of Spark Plugs

Lead fouling of aviation spark plugs is a condition likely to occur in any engine using leaded fuels. Lead is added to aviation fuel to improve its anti-knock qualities. The lead, however, has the undesirable effect of forming lead oxide during combustion. This lead oxide forms as a solid with varying degrees of hardness and consistency. Lead deposits on combustion chamber surfaces are good electrical conductors at high temperatures and cause misfiring. At low temperatures, the same deposits may be good insulators. In either case, lead formations on aircraft spark plugs prevent their normal operation. [Figure 2] To minimize the formation of lead deposits, ethylene dibromide is added to the fuel as a scavenging agent that combines with the lead during combustion.

|

| Figure 2. Lead fouled spark plug |

Lead fouling may occur at any power setting, but perhaps the power setting most conducive to lead fouling is cruising with lean mixtures. At this power, the cylinder head temperature is relatively low and there is more oxygen than needed to consume all the fuel in the fuel-air mixture. Oxygen, when hot, is very active and aggressive. When all the fuel has been consumed, some of the excess oxygen unites with some of the lead and some of the scavenger agent to form oxygen compounds of lead or bromine or both. Some of these undesirable lead compounds solidify and build up in layers as they contact the relatively cool cylinder walls and spark plugs. Although lead fouling may occur at any power setting, experience indicates that the lead buildup is generally confined to a specific combustion temperature range. Combustion temperatures outside this specific range minimize the lead fouling tendency.

If lead fouling is detected before the spark plugs become completely fouled, the lead can usually be eliminated or reduced by either a sharp rise or a sharp decrease in combustion temperature. This imposes a thermal shock on cylinder parts, causing them to expand or contract. Since there is a different rate of expansion between deposits and metal parts on which they form, the deposits chip off or are loosened and then scavenged from the combustion chamber by the exhaust or are burned in the combustion process.

Several methods of producing thermal shock to cylinder parts are used. The method used depends on the accessory equipment installed on the engine. A sharp rise in combustion temperatures can be obtained on all engines by operating them at full takeoff power for approximately 1 minute. When using this method to eliminate fouling, the propeller control must be placed in low pitch, or high rpm, and the throttle advanced slowly to produce takeoff rpm and manifold pressure. Slow movement of the throttle control provides reasonable freedom from backfiring in the affected cylinders during the application of power.

Another method of producing thermal shock is the use of excessively rich fuel-air mixtures. This method suddenly cools the combustion chamber because the excess fuel does not contribute to combustion; instead, it absorbs heat from the combustion area. Some carburetor installations use two-position manual mixture controls that provide a lean mixture setting for cruising economy and a richer mixture setting for all powers above cruising. Neither manual mixture control setting in this type of configuration is capable of producing an excessively rich fuel-air mixture. Even when the engine is operated in auto-rich at powers where an auto-lean setting would be entirely satisfactory, the mixture is not rich enough.

[ad-long]

Graphite Fouling of Spark Plugs

As a result of careless and excessive application of thread lubricant, called antiseize compound, to the spark plug, the lubricant flows over the electrodes and causes shorting. Shorting occurs because graphite is a good electrical conductor. The elimination of service difficulties caused by graphite is up to the aircraft technician. Use care when applying the lubricant to make certain that smeared fingers, shop towels, or brushes do not contact the electrodes or any part of the ignition system except the spark plug threads. Never apply to the first set of threads.

Gap Erosion of Spark Plugs

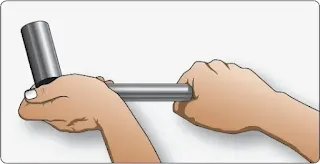

Erosion of the electrodes takes place in all aircraft spark plugs as the spark jumps the air gap between the electrodes. [Figure 3]

|

| Figure 3. Spark plug gap erosion |

The spark carries with it a portion of the electrode, part of which is deposited on the other electrode. The remainder is blown off in the combustion chamber. As the airgap is enlarged by erosion, the resistance that the spark must overcome in jumping the air gap also increases. This means that the magneto must produce a higher voltage to overcome the higher resistance. With higher voltages in the ignition system, a greater tendency exists for the spark to discharge at some weak insulation point in the ignition system. Since the resistance of an air gap also increases as the pressure in the engine cylinder increases, a double danger exists at takeoff and during sudden acceleration with enlarged airgaps. Insulation breakdown, premature flashover, and carbon tracking result in misfiring of the spark plug and go hand in hand with excessive spark plug gap. Wide gap settings also raise the coming in speed of a magneto and therefore cause hard starting.

Spark plug manufacturers have partially overcome the problem of gap erosion by using a hermetically sealed resistor in the center electrode of spark plugs. This added resistance in the high-tension circuit reduces the peak current at the instant of firing. This reduced current flow helps prevent metal disintegration in the electrodes. Also, due to the high erosion rate of steel or any of its known alloys, spark plug manufacturers are using tungsten or an alloy of nickel for their massive electrode plugs and iridium/platinum plating for their fine wire electrode plugs.

Spark Plug Removal

Spark plugs should be removed for inspection and servicing at the intervals recommended by the manufacturer. Since the rate of gap erosion varies with different operating conditions, engine models, and type of spark plug, engine malfunction traceable to faulty spark plugs may occur before the regular servicing interval is reached. Normally, in such cases, only the faulty plugs are replaced.

Since spark plugs can be easily damaged, careful handling of the used and replacement plugs during installation and removal of spark plugs from an engine cannot be overemphasized. To prevent damage, spark plugs should always be handled individually and new and reconditioned plugs should be stored in separate cartons. A common method of storage is illustrated in Figure 4. This is a drilled tray, which prevents the plugs from bumping against one another and damaging the fragile insulators and threads. If a plug is dropped on the floor or other hard surface, it should not be installed in an engine, since the shock of impact usually causes small, invisible cracks in the insulators. A dropped spark plug should be discarded.

|

| Figure 4. Spark plug tray |

Before a spark plug can be removed, the ignition harness lead must be disconnected. Using the special spark plug coupling elbow wrench, loosen and remove the spark plug to elbow coupling nut from the spark plug. Take care to pull the lead straight out and in line with the centerline of the plug barrel. If a side load is applied, damage to the barrel insulator and the ceramic lead terminal may result. [Figure 5] If the lead cannot be removed easily in this manner, the neoprene collar may be stuck to the shielding barrel. Break loose the neoprene collar by twisting the collar as though it were a nut being unscrewed from a bolt.

|

| Figure 5. Improper lead removal technique |

After the lead has been disconnected, select the proper size deep socket for spark plug removal. Apply steady pressure with one hand on the hinge handle, holding the socket in alignment with the other hand. Failure to hold the socket in correct alignment causes the socket to tilt to one side and damage the spark plug. [Figure 6]

|

| Figure 6. Proper spark plug removal technique |

In the course of engine operation, carbon and other products of combustion are deposited across the spark plug and cylinder, and some carbon may even penetrate the lower threads of the shell. As a result, a high torque is generally required to break the spark plug loose. This factor imposes a shearing load on the shell section of the plug. After removing the plugs, they should be placed in a spark plug tray. [Figure 4]

[ad-longer]

Spark Plug Reconditioning Service

A visual inspection should be the first step in servicing spark plugs. The threads on the shielding barrel and on the shell that screws into the cylinder should be inspected for damaged or nicked threads. Inspect the lead shielding barrel for corrosion, nicks, and cracks. The firing end should be checked for insulator cracks, chips, and excessive electrode wear. The shell hex or wrench hex should be checked to see if it is rounded off or mutilated. If the spark plug passes the visual check, then it should be degreased using petroleum solvent. Take care to keep solvent out of the shielding barrel.

Never soak the plugs in solvent. After drying the firing end of the plugs, remove the lead compound deposits using a vibrator cleaner. [Figure 7] The firing end can now be cleaned by using an abrasive blaster.

|

| Figure 7. Spark plug vibrator cleaner |

This is usually done using a spark plug cleaner tester. [Figure 8] As the firing end is subjected to the abrasive blast, the plug should be rotated so all the area of the firing end is cleaned. After the abrasive blast, the firing end gets a thorough air blast to remove the abrasive material. The shielding barrel insulators may be cleaned with a cotton cloth or felt swab saturated with solvent, wood alcohol, or other approved cleaner. The firing end should be inspected using a light and a magnifying glass. If the plug passes the firing end visual and cleaning checks, then the spark gap should be set using a round thickness gauge. The spark plug should be tested by using a tester as shown in Figure 8, which passes a high-voltage through the spark plug and fire the gap. As this test takes place, the firing end of the plug is subjected to air pressure to simulate the pressure in the engine’s cylinder. If the firing pattern is good, the plug should be returned to its holder ready for installation in the engine.

|

| Figure 8. Spark plug cleaner tester |

Inspection Prior to Installation

Before installing new or reconditioned spark plugs in the engine cylinders, clean the spark plug bushings or Heli-Coil inserts.

Brass or stainless steel spark plug bushings are usually cleaned with a spark plug bushing cleanout tap. Before inserting the cleanout tap in the spark plug hole, fill the flutes of the tap, or channels between threads, with clean grease to prevent hard carbon or other material removed by the tap from dropping into the inside of the cylinder. Align the tap with the bushing threads by sight where possible, and start the tap by hand until there is no possibility of it being cross-threaded in the bushing. To start the tap on installations where the spark plug hole is located deeper than can be reached by a clenched hand, it may be necessary to use a short length of hose slipped over the square end of the tap to act as an extension. When screwing the tap into the bushing, be sure that the full tap cutting thread reaches the bottom thread of the bushing. This removes carbon deposits from the bushing threads without removing bushing metal, unless the pitch diameter of the threads has contracted as the result of shrinkage or some other unusual condition. Replace the cylinder if, during the thread-cleaning process, the bushing is found to be loose, loosened in the cylinder, or the threads are cross-threaded or otherwise seriously damaged.

Spark plug Heli-Coil inserts are cleaned with a round wire brush, preferably one having a diameter slightly larger than the diameter of the spark plug hole. A brush considerably larger than the hole may cause removal of material from the Heli-Coil proper or from the cylinder head surrounding the insert. Also, the brush should not disintegrate with use, allowing wire bristles to fall into the cylinder. Clean the insert by carefully rotating the wire brush with a power tool. When using the power brush, be careful that no material is removed from the spark plug gasket seating surface, since this may cause a change in the spark plug’s heat range, combustion leakage, and eventual cylinder damage. Never clean the Heli-Coil inserts with a cleaning tap, since permanent damage to the insert results. If a Heli-Coil insert is damaged as a result of normal operation or while cleaning it, replace it according to the applicable manufacturer’s instructions.

Using a lint-free rag and cleaning solvent, wipe the spark plug gasket seating surface of the cylinder to eliminate the possibility of dirt or grease being accidentally deposited on the spark plug electrodes at the time of installation.

Before the new or reconditioned plugs are installed, they must be inspected for each of the following conditions:

- Ensure that the plug is of the approved type, as indicated by the applicable manufacturer’s instructions.

- Check for evidence of rust-preventive compound on the spark plug exterior and core insulator and on the inside of the shielding barrel. Rust-preventive compound accumulations are removed by washing the plug with a brush and cleaning solvent. It must then be dried with a dry air blast.

- Check both ends of the plug for nicked or cracked threads and any indication of cracks in the nose insulator.

- Inspect the inside of the shielding barrel for cracks in the barrel insulator, and the center electrode contact for rust and foreign material that might cause poor electrical contact.

- Install a new spark plug gasket. When the thermocouple gasket is used, do not use an additional gasket.

The gap setting should be checked with a round wire-thickness gauge. [Figure 9] A flat-type gauge gives an incorrect clearance indication because the massive ground electrodes are contoured to the shape of the round center electrode. When using the wire thickness gauge, insert the gauge in each gap parallel to the centerline of the center electrode. If the gauge is tilted slightly, the indication is incorrect. Do not install a plug that does not have an air gap within the specified clearance range.

|

| Figure 9. Wire gap gauge |

Spark Plug Installation

Prior to spark plug installation, carefully coat the first two or three threads from the electrode end of the shell with a graphite base antiseize compound. Prior to application, stir the antiseize compound to ensure thorough mixing. When applying the antiseize compound to the threads, be extremely careful that none of the compound gets on the ground, center electrodes, or on the nose of the plug, where it can spread to the ground or center electrode during installation. This precaution is mentioned because the graphite in the compound is an excellent electrical conductor and could cause permanent fouling.

To install a spark plug, start it into the cylinder without using a wrench of any kind, and turn it until the spark plug is seated on the gasket. If you can screw the plug into the cylinder with comparative ease using your fingers, this indicates good, clean threads. In this case, only a small amount of additional tightening torque is needed to compress the gasket to form a gastight seal. If a high torque is needed to install the plug, dirty or damaged threads on either the plug or plug bushing are indicated. The use of excessive torque might compress the gasket out of shape and distort and stretch the plug shell to a point where breakage would result during the next removal or installation. Shell stretching occurs as excessive torque continues to screw the lower end of the shell into the cylinder after the upper end has been stopped by the gasket shoulder. As the shell stretches, the seal between the shell and core insulator is opened, creating a loss of gas tightness or damage to the core insulator. After a spark plug has been seated with the fingers, use a torque wrench and tighten to the specified torque. [Figure 10]

|

| Figure 10. Effect of excessive torque in installing a spark plug |

Spark Plug Lead Installation

Before installing the spark plug lead, carefully wipe the terminal sleeve and the integral seal with a cloth moistened with acetone or an approved solvent. After the plug lead is cleaned, inspect it for cracks and scratches. If the terminal sleeve is damaged or heavily stained, replace it.

Application of a light coating of an insulating material to the outer surface of the terminal sleeve, as well as filling the space occupied by the contact spring, is sometimes recommended. By occupying the space in the electrical contact area of the shielding barrel, the insulating material prevents moisture from entering the contact area and shorting the spark plug. Some manufacturers recommend the use of such insulating compounds only when moisture in the ignition system becomes a problem, and others have discontinued the use of such materials.

After inspection of the spark plug lead, slip the lead into the shielding barrel of the plug with care. Then, tighten the spark plug coupling elbow nut with the proper tool. Most manufacturers’ instructions specify the use of a tool designed to help prevent an overtorque condition. After the coupling nut is tightened, avoid checking for tightness by twisting the body of the elbow.

After all plugs have been installed, torqued, and the leads properly installed, start the engine and perform a complete ignition system operational check.

[ad-longest]

Breaker Point Inspection

Inspection of the magneto consists essentially of a periodic breaker point and dielectric inspection. After the magneto has been inspected for security of mounting, remove the magneto cover, or breaker cover, and check the cam for proper lubrication. Under normal conditions, there is usually ample oil in the felt oiler pad of the cam follower to keep the cam lubricated between overhaul periods. However, during the regular routine inspection, examine the felt pad on the cam follower to be sure it contains sufficient oil for cam lubrication. Make this check by pressing the thumbnail against the oiler pad. If oil appears on the thumbnail, the pad contains sufficient oil for cam lubrication. If there is no evidence of oil on the fingernail, apply one drop of a light aircraft engine oil to the bottom felt pad and one drop to the upper felt pad of the follower assembly. [Figure 11]

|

| Figure 11. Felt lubricator |

After application, allow at least 15 minutes for the felt to absorb the oil. At the end of 15 minutes, blot off any excess oil with a clean, lint-free cloth. During this operation, or any time the magneto cover is off, use extreme care to keep the breaker compartment free of oil, grease, or engine cleaning solvents, since each of these have an adhesiveness that collects dirt and grime that could foul an otherwise good set of breaker contact points.

After the felt oiler pad has been inspected, serviced, and found to be satisfactory, visually inspect the breaker contacts for any condition that may interfere with proper operation of the magneto. If the inspection reveals an oily or gummy substance on the sides of the contacts, swab the contacts with a flexible wiper, such as a pipe cleaner dipped in acetone or other approved solvent. By forming a hook on the end of the wiper, ready access can be gained to the back side of the contacts.

To clean the contact mating surfaces, force open the breaker points enough to admit a small swab. Whether spreading the points for purposes of cleaning or checking the surfaces for condition, always apply the opening force at the outer end of the mainspring and never spread the contacts more than 1⁄16 inch. If the contacts are spread wider than recommended, the mainspring, the spring carrying the movable contact point, is likely to take a permanent set. If the mainspring takes a permanent set, the movable contact point loses some of its closing tension and the points then either bounce or float, preventing the normal induction buildup of the magneto.

A swab can be made by wrapping a piece of linen tape or a small piece of lint-free cloth over one of the leaves of a clearance gauge and dipping the swab in an approved solvent. Pass the swab between the carefully separated contact surfaces until the surfaces are clean. During this entire operation, take care that drops of solvent do not fall on lubricated parts, such as the cam, follower block, or felt oiler pad.

|

| Figure 12. Normal contact surface |

To inspect the breaker contact surfaces, it is necessary to know what a normal operating set of contacts looks like, what surface condition is considered as permissible wear, and what surface condition is cause for dressing or replacement. The probable cause of an abnormal surface condition can be determined from the contact appearance. The normal contact surface has a dull gray, sandblasted, almost rough appearance over the area where electrical contact is made. [Figure 12] This gray, sandblasted appearance indicates that the points have worn in and have mated to each other and are providing the best possible electrical contact. This does not imply that this is the only acceptable contact surface condition. Slight, smooth-surfaced irregularities, without deep pits or high peaks, such as shown in Figure 13, are considered normal wear and are not cause for replacement.

|

| Figure 13. Points with normal irregularities |

However, when wear advances to a point where the slight, smooth irregularities develop into well-defined peaks extending noticeably above the surrounding surface, the breaker contacts must be replaced. [Figure 14]

Unfortunately, when a peak forms on one contact, the mating contact has a corresponding pit or hole. This pit is more troublesome than the peak because it penetrates the platinum pad of the contact surface. It is sometimes difficult to judge whether a contact surface is pitted deeply enough to require replacement because this depends on how much of the original platinum is left on the contact surface. The danger arises from the possibility that the platinum pad may already be thin as a result of long service life and previous dressings.

|

| Figure 14. Points with well-defined peaks |

At overhaul facilities, a gauge is used to measure the remaining thickness of the pad, and no difficulty in determining the condition of the pad exists. But at line maintenance activities, this gauge is generally unavailable. Therefore, if the peak is quite high or the pit quite deep, remove and replace them with a new assembly. A comparison between Figures 13 and 14 will help to draw the line between minor irregularities and well-defined peaks.

Some examples of possible breaker contact surface conditions are illustrated in Figure 15. Item A illustrates an example of erosion or wear called frosting. This condition results from an open-circuited condenser and is easily recognized by the coarse, crystalline surface and the black “sooty” appearance of the sides of the points. The lack of effective condenser action results in an arc of intense heat being formed each time the points open. This, together with the oxygen in the air, rapidly oxidizes and erodes the platinum surface of the points, producing the coarse, crystalline, or frosted appearance. Properly operating points have a fine-grained, frosted, or silvery appearance and should not be confused with the coarse-grained and sooty point caused by faulty condenser action.

|

| Figure 15. Examples of contact surface conditions |

Figure 15B and C illustrate badly pitted points. In the early stage, these points are identified by a fairly even contact edge and minute pits or pocks in or near the center of the contact surface with an overall smoky appearance. In more advanced stages, the pit may develop into a large, jagged crater, and eventually the entire contact surface takes on a burned, black, and crumpled appearance. Pitted points, as a general rule, are caused by dirt and impurities on the contact surfaces. If points are excessively pitted, a new breaker assembly must be installed.

Figure 15E illustrates a built-up point that can be recognized by the mound of metal that has been transferred from one point to another. Buildup, like the other conditions mentioned, results primarily from the transfer of contact material by means of the arc as the points separate. But, unlike the others, there is no burning or oxidation in the process because of the closeness of the pit of one point and the buildup of the other. This condition may result from excessive breaker point spring tension that retards the opening of the points or causes a slow, lazy break. It can also be caused by a poor primary condenser or a loose connection at the primary coil. If excessive buildup has occurred, a new breaker assembly must be installed.

Figure 15F illustrates oily points that can be recognized by their smoked and smudged appearance and by the lack of any of the previously mentioned irregularities. This condition may be the result of excessive cam lubrication or of oil vapors that may come from within or outside the magneto. A smoking or fuming engine, for example, could produce the oil vapors. These vapors then enter the magneto through the magneto ventilator and pass between and around the points. These conductive vapors produce arcing and burning on the contact surfaces. The vapors also adhere to the other surfaces of the breaker assembly and form the sooty deposit. If so, install new breaker assembly.

[ad-in5]

Dielectric Inspection

Another phase of magneto inspection is the dielectric inspection. This inspection is a visual check for cleanliness and cracks. If inspection reveals that the coil cases, condensers, distributor rotor, or blocks are oily or dirty or have any trace of carbon tracking, they require cleaning and possibly waxing to restore their dielectric qualities.

Clean all accessible condensers and coil cases that contain condensers by wiping them with a lint-free cloth moistened with acetone. Many parts of this type have a protective coating. This protective coating is not affected by acetone, but it may be damaged by scraping or by the use of other cleaning fluids. Never use unapproved cleaning solvents or improper cleaning methods. Also, when cleaning condensers or parts that contain condensers, do not dip, submerge, or saturate the parts in any solution because the solution used may seep inside the condenser and short out the plates.

Coil cases, distributor blocks, distributor rotors, and other dielectric parts of the ignition system are treated with a wax coating when they are new and again at overhaul. The waxing of dielectrics aids their resistance to moisture absorption, carbon tracking, and acid deposits. When these parts become dirty or oily, some of the original protection is lost, and carbon tracking may result.

If any hairline carbon tracks or acid deposits are present on the surface of the dielectric, immerse the part in approved cleaning solvent and scrub it vigorously with a stiff bristle brush. When the carbon track or acid deposits have been removed, wipe the part with a clean, dry cloth to remove all traces of the solvent used for cleaning. Then, coat the part with a special ignition-treating wax. After wax treating the part, remove excess wax deposits and reinstall the part in the magneto.

Ignition Harness Maintenance

Although the ignition harness is simple, it is a vital link between the magneto and spark plug. Because the harness is mounted on the engine and exposed to the atmosphere, it is vulnerable to heat, moisture, and the effects of changing altitude. These factors, plus aging insulation and normal gap erosion, work against efficient engine operation. The insulation may break down on a wire inside the harness and allow the high-voltage to leak through the insulation to the harness shielding instead of going to the spark plug. Open circuits may result from broken wires or poor connections. A bare wire may be in physical contact with the shielding, or two wires may be shorted together.

Any serious defect in an individual lead prevents the high-tension impulse from reaching the spark plug to which the lead is connected. As a result, this plug will not fire. When only one spark plug is firing in a cylinder, the charge is not consumed as quickly as it would be if both plugs were firing. This factor causes the peak pressure of combustion to occur later on in the power stroke. If the peak pressure in the cylinder occurs later, a loss of power in that cylinder results. However, the power loss from a single cylinder becomes a minor factor when the effects of a longer burning time is considered. A longer burning time overheats the affected cylinder, causing detonation, possible preignition, and perhaps permanent damage to the cylinder.

High-Tension Ignition Harness Faults

Perhaps the most common and most difficult high-tension ignition system faults to detect are high-voltage leaks. This is leakage from the core conductor through insulation to the ground of the shielded manifold. A certain small amount of leakage exists even in brand new ignition cable during normal operation. Various factors combine to produce first a high rate of leakage and then complete breakdown. Of these factors, moisture in any form is probably the worst.

Under high-voltage stress, an arc forms and burns a path across the insulator where the moisture exists. If there is gasoline, oil, or grease present, it breaks down and forms carbon. The burned path is called a carbon track, since it is actually a path of carbon particles. With some types of insulation, it may be possible to remove the carbon track and restore the insulator to its former useful condition. This is generally true of porcelain, ceramics, and some of the plastics because these materials are not hydrocarbons and any carbon track forming on them is the result of a dirt film that can be wiped away.

Differences in location and amount of leakage produce different indications of malfunction during engine operation. Indications are generally misfiring or crossfiring. The indication may be intermittent, changing with manifold pressure or with climate conditions. An increase in manifold pressure increases the compression pressure and the resistance of the air across the air gap of the spark plugs. An increase in the resistance at the air gap opposes the spark discharge and produces a tendency for the spark to discharge at some weak point in the insulation. A weak spot in the harness may be aggravated by moisture collecting in the harness manifold. With moisture present, continued engine operation causes the intermittent faults to become permanent carbon tracks. Thus, the first indication of ignition harness unserviceability may be engine misfiring or roughness caused by partial leakage of the ignition voltage.

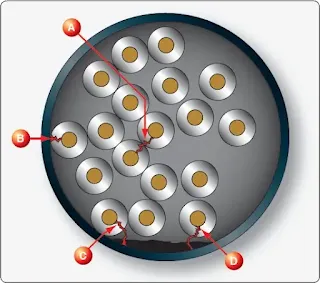

Figure 16 demonstrates four faults that may occur. Fault A shows a short from one cable conductor to another. This fault usually causes misfiring, since the spark is short circuited to a plug in a cylinder where the cylinder pressure is low. Fault B illustrates a cable with a portion of its insulation scuffed away. Although the insulation is not completely broken down, more than normal leakage exists, and the spark plug to which this cable is connected may be lost during takeoff when the manifold pressure is quite high. Fault C is the result of condensation collecting in the lowest portion of the ignition manifold. This condensation may completely evaporate during engine operation, but the carbon track that is formed by the initial flashover remains to allow continued flashover whenever high manifold pressure exists. Fault D may be caused by a flaw in the insulation or the result of a weak spot in the insulation that is aggravated by the presence of moisture. However, since the carbon track is in direct contact with the metal shielding, it probably results in flashover under all operating conditions.

|

| Figure 16. Cross section of an ignition harness |

Harness Testing

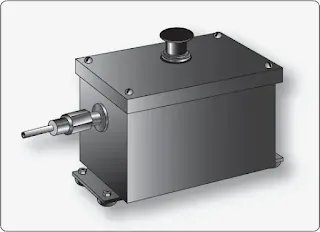

The electrical test of the ignition harness checks the condition or effectiveness of the insulation around each cable in the harness. [Figure 17] This test involves application of a definite voltage to each lead, and then measurement with a very sensitive meter of the amount of current leakage between the lead and the grounded harness manifold.

|

| Figure 17. Harness tester |

This reading, when compared with known specifications, becomes a guide to the condition or serviceability of the cable. As mentioned earlier, there is a gradual deterioration of flexible insulating material. When new, the insulation has a low rate of conductivity; so low that, under several thousand volts of electrical pressure, the current leakage is only a very few millionths of an ampere. Natural aging causes an extremely slow, but certain, change in the resistance of insulating material, allowing an ever-increasing rate of current leakage.