|

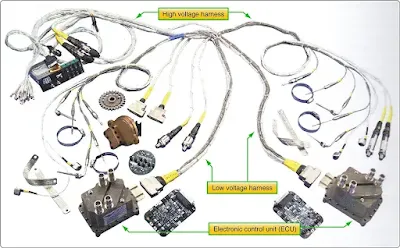

| Figure 1. PowerLink system components |

PowerLink provides control in both specified operating conditions and fault conditions. The system is designed to prevent adverse changes in power or thrust. In the event of loss of primary aircraft-supplied power, the engine controls continue to operate using a secondary power source (SPS). As a control device, the system performs self-diagnostics to determine overall system status and conveys this information to the pilot by various indicators on the health status annunciator (HSA) panel. PowerLink is able to withstand storage temperature extremes and operate at the same capacity as a non-FADEC-equipped engine in extreme heat, cold, and high humidity environments.

Low-Voltage Harness

The low-voltage harness connects all essential components of the FADEC System. [Figure 1] This harness acts as a signal transfer bus interconnecting the electronic control units (ECUs) with aircraft power sources, the ignition switch, speed sensor assembly (SSA), temperature and pressure sensors. The fuel injector coils and all sensors, except the SSA and fuel pressure and manifold pressure sensors, are hardwired to the low-voltage harness. This harness transmits sensor inputs to the ECUs through a 50-pin connector. The harness connects to the engine-mounted pressure sensors via cannon plug connectors. The 25-jpin connectors connect the harness to the speed sensor signal conditioning unit. The low-voltage harness attaches to the cabin harness by a firewall-mounted data port through the same cabin harness/ bulkhead connector assembly. The bulkhead connectors also supply the aircraft electrical power required to run the system.

The ECU is at the heart of the system, providing both ignition and fuel injection control to operate the engine with the maximum efficiency realizable. Each ECU contains two microprocessors, referred to as a computer, that control two cylinders. Each computer controls its own assigned cylinder and is capable of providing redundant control for the other computer’s cylinder.

The computer constantly monitors the engine speed and timing pulses developed from the camshaft gear as they are detected by the SSA. Knowing the exact engine speed and the timing sequence of the engine, the computers monitor the manifold air pressure and manifold air temperature to calculate air density and determine the mass air flow into the cylinder during the intake stroke. The computers calculate the percentage of engine power based on engine revolutions per minute (rpm) and manifold air pressure.

From this information, the computer can then determine the fuel required for the combustion cycle for either best power or best economy mode of operation. The computer precisely times the injection event, and the duration of the injector should be on time for the correct fuel-to-air ratio. Then, the computer sets the spark ignition event and ignition timing, again based on percentage of power calculation. Exhaust gas temperature is measured after the burn to verify that the fuel-to-air ratio calculations were correct for that combustion event. This process is repeated by each computer for its own assigned cylinder on every combustion/power cycle.

The computers can also vary the amount of fuel to control the fuel-to-air ratio for each individual cylinder to control both cylinder head temperature (CHT) and exhaust gas temperature (EGT).

[ad-mid]

Electronic Control Unit (ECU)

An ECU is assigned to a pair of engine cylinders. [Figure 2] The ECUs control the fuel mixture and spark timing for their respective engine cylinders; ECU 1 controls opposing cylinders 1 and 2, ECU 2 controls cylinders 3 and 4, and ECU 3 controls cylinders 5 and 6. Each ECU is divided into upper and lower portions. The lower portion contains an electronic circuit board, while the upper portion houses the ignition coils. Each electronic control board contains two independent microprocessor controllers that serve as control channels. During engine operation, one control channel is assigned to operate a single engine cylinder. Therefore, one ECU can control two engine cylinders, one control channel per cylinder. The control channels are independent, and there are no shared electronic components within one ECU. They also operate on independent and separate power supplies. However, if one control channel fails, the other control channel in the pair within the same ECU is capable of operating both its assigned cylinder and the other opposing engine cylinder as backup control for fuel injection and ignition timing. Each control channel on the ECU monitors the current operating conditions and operates its cylinder to attain engine operation within specified parameters.

|

| Figure 2. Electronic control unit |

The following transmit inputs to the control channels across the low-voltage harness:

- Speed sensor that monitors engine speed and crank position

- Fuel pressure sensors

- Manifold pressure sensors

- Manifold air temperature (MAT) sensors

- CHT sensors

- EGT sensors

All critical sensors are dually redundant with one sensor from each type of pair connected to control channels in different ECUs. Synthetic software default values are also used in the unlikely event that both sensors of a redundant pair fail. The control channel continuously monitors changes in engine speed, manifold pressure, manifold temperature, and fuel pressure based on sensor input relative to operating conditions to determine how much fuel to inject into the intake port of the cylinder.

[ad-long]

PowerLink Ignition System

The ignition system consists of the high-voltage coils atop the ECU, the high-voltage harness, and spark plugs. Since there are two spark plugs per cylinder on all engines, a six-cylinder engine has 12 leads and 12 spark plugs. One end of each lead on the high-voltage harness attaches to a spark plug, and the other end of the lead wire attaches to the spark plug towers on each ECU. The spark tower pair is connected to opposite ends of one of the ECU’s coil packs. Two coil packs are located in the upper portion of the ECU. Each coil pack generates a high-voltage pulse for two spark plug towers. One tower fires a positive polarity pulse and the other of the same coil fires a negative polarity pulse. Each ECU controls the ignition spark for two engine cylinders. The control channel within each ECU commands one of the two coil packs to control the ignition spark for the engine cylinders. [Figure 3] The high-voltage harness carries energy from the ECU spark towers to the spark plugs on the engine.

|

| Figure 3. Ignition control |

For both spark plugs in a given cylinder to fire on the compression stroke, both control channels must fire their coil packs. Each coil pack has a spark plug from each of the two cylinders controlled by that ECU unit.

The ignition spark is timed to the engine’s crankshaft position. The timing is variable throughout the engine’s operating range and is dependent upon the engine load conditions. The spark energy is also varied with respect to the engine load.

NOTE: Engine ignition timing is established by the ECUs and cannot be manually adjusted.

RELATED POSTS