Built-In Engine Timing Reference Marks

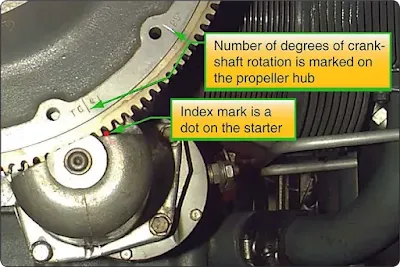

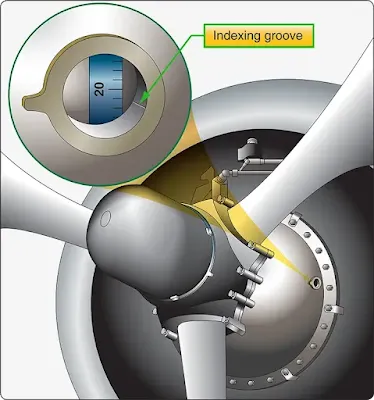

Most reciprocating engines have timing reference marks built into the engine. The timing reference marks vary by manufacturer. [Figure 1] When the starter gear hub is installed correctly, the timing marks are marked on it that line up with the mark on the starter. On an engine that has no starter gear hub, the timing mark is normally on the propeller flange edge. [Figure 2] The top center (TC) mark stamped on the edge aligns with the crankcase split line below the crankshaft when the No. 1 piston is at top dead center. Other flange marks indicate degrees before top center.

|

| Figure 1. Lycoming timing marks |

|

| Figure 2. Propeller flange timing marks |

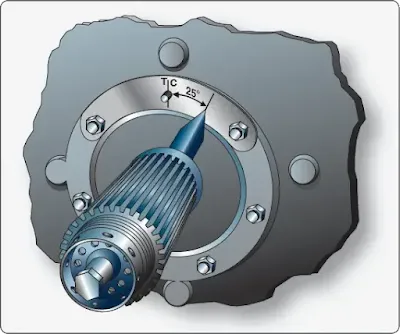

Some engines have degree markings on the propeller reduction drive gear. To time these engines, the plug provided on the exterior of the reduction gear housing must be removed to view the timing marks. On other engines, the timing marks are on a crankshaft flange and can be viewed by removing a plug from the crankcase. In every case, the engine manufacturer’s instructions give the location of built-in timing reference marks.

In using built-in timing marks to position the crankshaft, be sure to sight straight across the stationary pointer or mark on the nose section, the propeller shaft, crankshaft flange, or bell gear. [Figure 3] Sighting at an angle results in an error in positioning the crankshaft. Normally, the No. 1 cylinder is used to time or check the timing of the magnetos. When installing magnetos, the timing marks must be lined up and the No. 1 cylinder must be on the compression stroke.

|

| Figure 3. Typical built-in timing mark on propeller reduction gear |

The amount of gear backlash in any system of gears varies between installations because there is clearance between the gear teeth. Always take timing when reading, or stop movement of the engine for timing set up, in the direction of rotation. Another unfavorable aspect in the use of timing marks on the reduction gear is the small error that exists when sighting down the reference mark to the timing mark inside the housing on the reduction gear. This can occur because there is depth between the two reference marks.

Timing Disks

Most timing disk devices are mounted to the crankshaft flange and use a timing plate. [Figure 4-] The markings vary according to the specifications of the engine. This plate is temporarily installed on the crankshaft flange with a scale numbered in crankshaft degrees and the pointer attached to the timing disk.

|

| Figure 4. A timing plate and pointer |

Piston Position Indicators

Any given piston position, whether it is to be used for ignition, valve, or injection pump timing, is referenced to a piston position called top dead center. This piston position is not to be confused with a piston position called top center. A piston in top center has little value from a timing standpoint because the corresponding crankshaft position may vary from 1° to 5° for this piston position. This is illustrated in Figure 5, which is exaggerated to emphasize the no-travel zone of the piston. Notice that the piston does not move while the crankshaft describes the small arc from position A to position B.

|

| Figure 5. Difference between top center and top dead center |

This no-travel zone occurs between the time the crankshaft and connecting rod stop pushing the piston upward, and continues until the crankshaft has swung the lower end of the connecting rod into a position where the crankshaft can start pulling the piston downward. Top dead center is a piston and crankshaft position from which all other piston and crankshaft locations are referenced. When a piston is in the top dead center position of the crankshaft, it is also in the center of the no-travel zone. The piston is in a position where a straight line can be drawn through the center of the crankshaft journal, the crankpin, and the piston pin. This is shown on the right of Figure 5. With such an alignment, a force applied to the piston could not move the crankshaft.

Timing Lights

Timing lights are used to help determine the exact instant that the magneto points open. There are two general types of timing lights in common use. Both have two lights and three external wire connections. Although both have internal circuits that are somewhat different, their function is very much the same. [Figure 6 and 7]

|

| Figure 6. E50 Magneto Synchronizer |

|

| Figure 7. Timing light |

Three wires plug into the light box. [Figure 7] There are two lights on the front face of the unit, one green and one red, and a switch to turn the unit on and off. To use the timing light, the center lead, which is black, marked “ground lead” is connected to the case of the magneto being tested. The other leads are connected to the primary leads of the breaker point assembly of the magnetos being timed. The color of the lead corresponds to the color of the light on the timing light.

With the leads connected in this manner, it can be easily determined whether the points are open or closed by turning on the switch and observing the two lights. If the points are closed, most of the current flows through the breaker points and not through the transformers, and the lights do not come on. If the points are open, the current flows through the transformer and the lights glow. Some models of timing lights operate in the reverse manner (i.e., the light goes out when the points open). Each of the two lights is operated separately by the set of breaker points to which it is connected. This makes it possible to observe the time, or point in reference to magneto rotor rotation, that each set of points opens.

Most timing lights use batteries that must be replaced after long use. Attempts to use a timing light with weak batteries may result in erroneous readings because of low current flow in the circuits.