Airframe, engine, and aircraft component manufacturers are responsible for documenting the maintenance procedures that guide managers and technicians on when and how to perform maintenance on their products. A small aircraft may only require a few manuals, including the aircraft maintenance manual. This volume usually contains the most frequently used information required to maintain the aircraft properly. The Type Certificate Data Sheet (TCDS) for an aircraft also contains critical information. Complex and large aircraft require several manuals to convey correct maintenance procedures adequately. In addition to the maintenance manual, manufacturers may produce such volumes as structural repair manuals, overhaul manuals, wiring diagram manuals, component manuals, and more.

Note that the use of the word “manual” is meant to include electronic as well as printed information. Also, proper maintenance extends to the use of designated tools and fixtures called out in the manufacturer’s maintenance documents. In the past, not using the proper tooling has caused damage to critical components, which subsequently failed and led to aircraft crashes and the loss of human life. The technician is responsible for sourcing the correct information, procedures, and tools needed to perform airworthy maintenance or repairs.

Standard aircraft maintenance procedures do exist and can be used by the technician when performing maintenance or a repair. These are found in the Federal Aviation Administration (FAA) approved advisory circulars (AC) 43.13-2 and AC 43.13-1. If not addressed by the manufacturer’s literature, the technician may use the procedures outlined in these manuals to complete the work in an acceptable manner. These procedures are not specific to any aircraft or component and typically cover methods used during maintenance of all aircraft. Note that the manufacturer’s instructions supersede the general procedures found in AC 43.13-2 and AC 43.13-1.

All maintenance related actions on an aircraft or component are required to be documented by the performing technician in the aircraft or component logbook. Light aircraft may have only one logbook for all work performed. Some aircraft may have a separate engine logbook for any work performed on the engine(s). Other aircraft have separate propeller logbooks. Large aircraft require volumes of maintenance documentation comprised of thousands of procedures performed by hundreds of technicians. Electronic dispatch and recordkeeping of maintenance performed on large aircraft such as airliners is common. The importance of correct maintenance recordkeeping should not be overlooked.

[ad-mid]

Location Numbering Systems

Even on small, light aircraft, a method of precisely locating each structural component is required. Various numbering systems are used to facilitate the location of specific wing frames, fuselage bulkheads, or any other structural members on an aircraft. Most manufacturers use some system of station marking. For example, the nose of the aircraft may be designated “zero station,” and all other stations are located at measured distances in inches behind the zero station. Thus, when a blueprint reads “fuselage frame station 137,” that particular frame station can be located 137 inches behind the nose of the aircraft.

To locate structures to the right or left of the center line of an aircraft, a similar method is employed. Many manufacturers consider the center line of the aircraft to be a zero station from which measurements can be taken to the right or left to locate an airframe member. This is often used on the horizontal stabilizer and wings.

The applicable manufacturer’s numbering system and abbreviated designations or symbols should always be reviewed before attempting to locate a structural member. They are not always the same. The following list includes location designations typical of those used by many manufacturers.

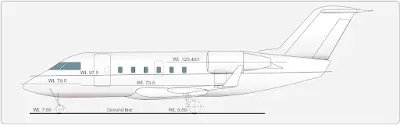

- Fuselage stations (Fus. Sta. or FS) are numbered in inches from a reference or zero point known as the reference datum. [Figure 1] The reference datum is an imaginary vertical plane at or near the nose of the aircraft from which all fore and aft distances are measured. The distance to a given point is measured in inches parallel to a center line extending through the aircraft from the nose through the center of the tail cone. Some manufacturers may call the fuselage station a body station, abbreviated BS.

|

| Figure 1. The various body stations relative to a single point of origin illustrated in inches or some other measurement (if of foreign development) |

- Buttock line or butt line (BL) is a vertical reference plane down the center of the aircraft from which measurements left or right can be made. [Figure 2]

|

| Figure 2. Butt line diagram of a horizontal stabilizer |

- Water line (WL) is the measurement of height in inches perpendicular from a horizontal plane usually located at the ground, cabin floor, or some other easily referenced location. [Figure 3]

|

| Figure 3. Water line diagram |

- Aileron station (AS) is measured outboard from, and parallel to, the inboard edge of the aileron, perpendicular to the rear beam of the wing.

- Flap station (KS) is measured perpendicular to the rear beam of the wing and parallel to, and outboard from, the inboard edge of the flap.

- Nacelle station (NC or Nac. Sta.) is measured either forward of or behind the front spar of the wing and perpendicular to a designated water line.

[ad-long]

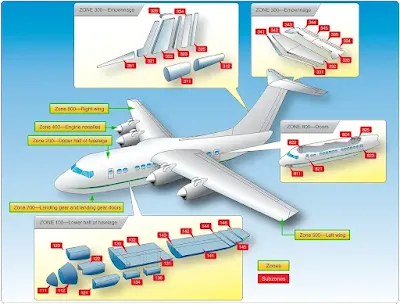

In addition to the location stations listed above, other measurements are used, especially on large aircraft. Thus, there may be horizontal stabilizer stations (HSS), vertical stabilizer stations (VSS) or powerplant stations (PPS). [Figure 4] In every case, the manufacturer’s terminology and station location system should be consulted before locating a point on a particular aircraft.

Another method is used to facilitate the location of aircraft components on air transport aircraft. This involves dividing the aircraft into zones. These large areas or major zones are further divided into sequentially numbered zones and subzones. The digits of the zone number are reserved and indexed to indicate the location and type of system of which the component is a part. Figure 5 illustrates these zones and subzones on a transport category aircraft.

|

| Figure 5. Large aircraft are divided into zones and subzones for identifying the location of various components |

Access and Inspection Panels

Knowing where a particular structure or component is located on an aircraft needs to be combined with gaining access to that area to perform the required inspections or maintenance. To facilitate this, access and inspection panels are located on most surfaces of the aircraft. Small panels that are hinged or removable allow inspection and servicing. Large panels and doors allow components to be removed and installed, as well as human entry for maintenance purposes.

The underside of a wing, for example, sometimes contains dozens of small panels through which control cable components can be monitored and fittings greased. Various drains and jack points may also be on the underside of the wing. The upper surface of the wings typically have fewer access panels because a smooth surface promotes better laminar airflow, which causes lift. On large aircraft, walkways are sometimes designated on the wing upper surface to permit safe navigation by mechanics and inspectors to critical structures and components located along the wing’s leading and trailing edges. Wheel wells and special component bays are places where numerous components and accessories are grouped together for easy maintenance access.

Panels and doors on aircraft are numbered for positive identification. On large aircraft, panels are usually numbered sequentially containing zone and subzone information in the panel number. Designation for a left or right side location on the aircraft is often indicated in the panel number. This could be with an “L” or “R,” or panels on one side of the aircraft could be odd numbered and the other side even numbered. The manufacturer’s maintenance manual explains the panel numbering system and often has numerous diagrams and tables showing the location of various components and under which panel they may be found. Each manufacturer is entitled to develop its own panel numbering system.