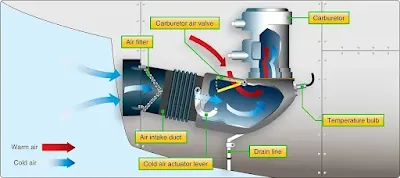

Figure 1 is a diagram of an induction system used in an engine equipped with a carburetor. In this induction system, carburetor normal flow air is admitted at the lower front nose cowling below the propeller spinner, and is passed through an air filter into air ducts leading to the carburetor. A carburetor heat air valve is located below the carburetor for selecting an alternate warm air source (carburetor heat) to prevent carburetor icing. [Figure 2]

|

| Figure 1. Nonsupercharged induction system using a carburetor |

|

| Figure 2. Location of a carburetor heat air valve |

Carburetor icing occurs when the temperature is lowered in the throat of the carburetor and enough moisture is present to freeze and block the flow of air to the engine. The carburetor heat valve admits air from the outside air scoop for normal operation, and it admits warm air from the engine compartment for operation during icing conditions. The carburetor heat is operated by a push-pull control in the cockpit. When the carburetor heat air door is closed, warm ducted air from around the exhaust is directed into the carburetor. This raises the intake air temperature. An alternate air door can be opened by engine suction if the normal route of airflow should be blocked by something. The valve is spring loaded closed and is sucked open by the engine if needed.

The carburetor air filter, shown in Figure 3, is installed in the air scoop in front of the carburetor air duct. Its purpose is to stop dust and other foreign matter from entering the engine through the carburetor. The screen consists of an aluminum alloy frame and a deeply crimped screen, arranged to present maximum screen area to the airstream. There are several types of air filters in use including paper, foam, and other types of filters. Most air filters require servicing at regular intervals and the specific instructions for the type of filter must be followed. [Figure 3]

|

| Figure 3. Location of air filter |

The carburetor air ducts consist of a fixed duct riveted to the nose cowling and a flexible duct between the fixed duct and the carburetor air valve housing. The carburetor air ducts normally provide a passage for outside air to the carburetor. Air enters the system through the ram-air intake. The intake opening is located in the slipstream so the air is forced into the induction system giving a ram effect to the incoming airflow. The air passes through the air ducts to the carburetor. The carburetor meters the fuel in proportion to the air and mixes the air with the correct amount of fuel. The throttle plate of the carburetor can be controlled from the cockpit to regulate the flow of air (manifold pressure), and in this way, power output of the engine can be controlled.

Although many newer aircraft are not so-equipped, some engines are equipped with carburetor air temperature indicating systems which shows the temperature of the air at the carburetor inlet. If the bulb is located at the engine side of the carburetor, the system measures the temperature of the fuel/air mixture.

[ad-mid]

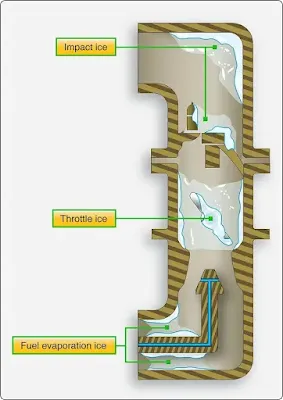

Induction System Icing

A short discussion concerning the formation and location of induction system ice is helpful, even though a technician’s not normally concerned with operations that occur when the aircraft is in flight. [Figure 4] Technicians should know something about induction system icing because of its effect on engine performance and troubleshooting. Even when an inspection shows that everything is in proper working order and the engine performs perfectly on the ground, induction system ice can cause an engine to act erratically and lose power in the air. Many engine troubles commonly attributed to other sources are actually caused by induction system icing.

|

| Figure 4. Location of a carburetor heat air valve |

Induction system icing is an operating hazard because it can cut off the flow of the fuel/air charge or vary the fuel/air ratio. Ice can form in the induction system while an aircraft is flying in clouds, fog, rain, sleet, snow, or even clear air that has high moisture content (high humidity). Induction system icing is generally classified in three types:

- Impact ice

- Fuel evaporation ice

- Throttle ice

Engine Fuel and Fuel Metering Systems section discusses types of icing in more detail.

Induction system ice can be prevented or eliminated by raising the temperature of the air that passes through the system, using a carburetor heat system located upstream near the induction system inlet and well ahead of the dangerous icing zones. This air is collected by a duct surrounding the exhaust manifold. Heat is usually obtained through a control valve that opens the induction system to the warm air circulating in the engine compartment and around the exhaust manifold.

Improper or careless use of carburetor heat can be just as dangerous as the most advanced stage of induction system ice. Increasing the temperature of the air causes it to expand and decrease in density. This action reduces the weight of the charge delivered to the cylinder and causes a noticeable loss in power because of decreased volumetric efficiency. In addition, high intake air temperature may cause detonation and engine failure, especially during takeoff and high power operation. Therefore, during all phases of engine operation, the carburetor temperature must afford the greatest protection against icing and detonation.

When there is danger of induction system icing, the cockpit carburetor heat control is moved to the hot position. Throttle ice or any ice that restricts airflow or reduces manifold pressure can best be removed by using full carburetor heat. If the heat from the engine compartment is sufficient and the application has not been delayed, it is only a matter of a few minutes until the ice is cleared.

When there is no danger of icing, the heat control is normally kept in the “cold” position. It is best to leave the control in this position if there are particles of dry snow or ice in the air. The use of heat may melt the ice or snow, and the resulting moisture may collect and freeze on the walls of the induction system. To prevent damage to the heater valves in the case of backfire, carburetor heat should not be used while starting the engine. Also, during ground operation only enough carburetor heat should be used to give smooth engine operation.

Part-throttle operation can lead to icing in the throttle area. When the throttle is placed in a partly closed position, it, in effect, limits the amount of air available to the engine. When the aircraft is in a glide, a fixed-pitch propeller windmills, causing the engine to consume more air than it normally would at this same throttle setting, thus adding to the lack of air behind the throttle. The partly closed throttle, under these circumstances, establishes a much higher than normal air velocity past the throttle, and an extremely low-pressure area is produced. The low-pressure area lowers the temperature of the air surrounding the throttle valve. If the temperature in this air falls below freezing and moisture is present, ice forms on the throttles and nearby units restricting the airflow to the engine causing it to quit. Throttle ice may be minimized on engines equipped with controllable-pitch propellers by the use of a higher than normal brake mean effective pressure (BMEP) at this low power. The high BMEP decreases the icing tendency because a large throttle opening at low engine revolutions per minute (rpm) partially removes the temperature-reducing obstruction that part-throttle operation offers.

[ad-long]

Induction System Filtering

Dust and dirt can be a serious source of trouble to an aircraft engine. Dust consists of small particles of hard, abrasive material that can be carried by the air and drawn into the engine cylinders. It can also collect on the fuel-metering elements of the carburetor, upsetting the proper relation between airflow and fuel flow at all engine power settings. It acts on the cylinder walls by grinding down these surfaces and the piston rings. Then, it contaminates the oil and is carried through the engine, causing further wear on the bearings and gears. In extreme cases, an accumulation may clog an oil passage and cause oil starvation. Although dust conditions are most critical at ground level, continued operation under such conditions without engine protection results in extreme engine wear and can produce excessive oil consumption. When operation in a dusty atmosphere is necessary, the engine can be protected by an alternate induction system air inlet which incorporates a dust filter. This type of air filter system normally consists of a filter element, a door, and an electrically operated actuator. When the filter system is operating, air is drawn through a louvered access panel that does not face directly into the airstream. With this entrance location, considerable dust is removed as the air is forced to turn and enter the duct. Since the dust particles are solid, they tend to continue in a straight line, and most of them are separated at this point. Those that are drawn into the louvers are easily removed by the filter.

In flight, with air filters operating, consideration must be given to possible icing conditions which may occur from actual surface icing or from freezing of the filter element after it becomes rain soaked. Some installations have a spring-loaded filter door which automatically opens when the filter is excessively restricted. This prevents the airflow from being cut off when the filter is clogged with ice or dirt. Other systems use an ice guard in the filtered-air entrance.

The ice guard consists of a coarse-mesh screen located a short distance from the filtered-air entrance. In this location, the screen is directly in the path of incoming air so that the air must pass through or around the screen. When ice forms on the screen, the air, which has lost its heavy moisture particles, passes around the iced screen and into the filter element. The efficiency of any filter system depends upon proper maintenance and servicing. Periodic removal and cleaning of the filter element is essential to satisfactory engine protection.

Induction System Inspection and Maintenance

The induction system should be checked for cracks and leaks during all regularly scheduled engine inspections. The units of the system should be checked for security of mounting. The system should be kept clean at all times, since pieces of rags or paper can restrict the airflow if allowed to enter the air intakes or ducts. Loose bolts and nuts can cause serious damage if they pass into the engine.

On systems equipped with a carburetor air filter, the filter should be checked regularly. If it is dirty or does not have the proper oil film, the filter element should be removed and cleaned. After it has dried, it is usually immersed in a mixture of oil and rust-preventive compound. The excess fluid should be allowed to drain off before the filter element is reinstalled. Paper-type filters should be inspected and replaced as needed.

Induction System Troubleshooting

Figure 5 provides a general guide to the most common induction system troubles.

| Probable Cause | Isolation Procedure | Correction |

|---|---|---|

| Engine fails to start | ||

| Induction system obstructed | Inspect air scoop and air ducts | Remove obstructions |

| Air leaks | Inspect carburetor mounting and intake pipes | Tighten carburetor and repair or replace intake pipe |

| Engine runs rough | ||

| Loose air ducts | Inspect air ducts | Tighten air ducts |

| Leaking intake pipes | Inspect intake pipe packing nuts | Tighten nuts |

| Engine valves sticking | Remove rocker arm cover and check valve action | Lubricate and free sticking valves |

| Bent or worn valve push rods | Inspect push rods | Replace worn or damaged push rods |

| Low power | ||

| Restricted intake duct | Examine intake duct | Remove restrictions |

| Broken door in carburetor air valve | Inspect air valve | Replace air valve |

| Dirty air filter | Inspect air filter | Clear air filter |

| Engine idles improperly | ||

| Shrunken intake packing | Inspect packing for proper fit | Replace packing |

| Hole in intake pipe | Inspect intake pipe | Replace defective intake pipes |

| Loose carburetor mounting | Inspect mount bolts | Tighten mount bolts |

Figure 5. Common problems for troubleshooting induction systems

RELATED POSTS- Engine Induction and Exhaust Systems

- Reciprocating Engine Induction Systems (Part 1)

- Supercharged Induction Systems (Reciprocating Engine Induction Systems - Part 3)

- Turbine Engine Inlet Systems

- Reciprocating Engine Exhaust System Maintenance Practices, Inspection and Failures

- Exhaust Systems With Turbocharger