|

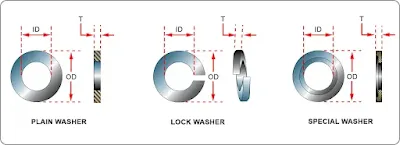

| Figure 1. Common types of washers used in airframe repair |

Plain Washers

Plain washers, both the AN960 and AN970, are used under hex nuts. [Figure 2] |

| Figure 2. Various types of washers |

They provide a smooth bearing surface and act as a shim in obtaining correct grip length for a bolt and nut assembly. They are used to adjust the position of castellated nuts in respect to drilled cotter pin holes in bolts. Use plain washers under lock washers to prevent damage to the surface material.

Aluminum and aluminum-alloy washers may be used under bolt heads or nuts on aluminum alloy or magnesium structures where corrosion caused by dissimilar metals is a factor. When used in this manner, any electric current flow is between the washer and the steel bolt. However, it is common practice to use a cadmium-plated steel washer under a nut bearing directly against a structure as this washer resists the cutting action of a nut better than an aluminum-alloy washer.

The AN970 steel washer provides a greater bearing area than the AN960 washer and is used on wooden structures under both the head and the nut of a bolt to prevent crushing the surface.

Lock washers should never be used under the following conditions:

Shake-proof lock washers can withstand higher heat than other methods of safetying and can be used under high vibration conditions safely. They should be used only once, because the tabs tend to break when bent a second time.

The NAS143 and MS20002 washers are used for internal wrenching bolts of the NAS144 through NAS158 series. This washer is either plain or countersunk. The countersunk washer (designated as NAS143C and MS20002C) is used to seat the bolt head shank radius, and the plain washer is used under the nut.

Aluminum and aluminum-alloy washers may be used under bolt heads or nuts on aluminum alloy or magnesium structures where corrosion caused by dissimilar metals is a factor. When used in this manner, any electric current flow is between the washer and the steel bolt. However, it is common practice to use a cadmium-plated steel washer under a nut bearing directly against a structure as this washer resists the cutting action of a nut better than an aluminum-alloy washer.

The AN970 steel washer provides a greater bearing area than the AN960 washer and is used on wooden structures under both the head and the nut of a bolt to prevent crushing the surface.

Lock Washers

Lock washers, both the AN935 and AN936, are used with machine screws or bolts where the self-locking or castellated-type nut is not appropriate. The spring action of the washer (AN935) provides enough friction to prevent loosening of the nut from vibration. [Figure 2]Lock washers should never be used under the following conditions:

- With fasteners to primary or secondary structures

- With fasteners on any part of the aircraft where failure might result in damage or danger to the aircraft or personnel

- Where failure would permit the opening of a joint to the airflow

- Where the screw is subject to frequent removal

- Where the washers are exposed to the airflow

- Where the washers are subject to corrosive conditions

- Where the washer is against soft material without a plain washer underneath to prevent gouging the surface

Shake-Proof Lock Washers

Shake-proof lock washers are round washers designed with tabs or lips that are bent upward across the sides of a hex nut or bolt to lock the nut in place. There are various methods of securing the lock washer to prevent it from turning, such as an external tab bent downward 90° into a small hole in the face of the unit or an internal tab that fits a keyed bolt.Shake-proof lock washers can withstand higher heat than other methods of safetying and can be used under high vibration conditions safely. They should be used only once, because the tabs tend to break when bent a second time.

Special Washers

The ball socket and seat washers, AC950 and AC955, are special washers used where a bolt is installed at an angle to a surface or where perfect alignment with a surface is required. These washers are used together. [Figure 2]The NAS143 and MS20002 washers are used for internal wrenching bolts of the NAS144 through NAS158 series. This washer is either plain or countersunk. The countersunk washer (designated as NAS143C and MS20002C) is used to seat the bolt head shank radius, and the plain washer is used under the nut.

RELATED POSTS

- Aircraft Materials, Hardware, and Processes

- Properties of Metals

- Aircraft Bolt

- Aircraft Nuts

- Installation and Safetying of Nuts, Washers, & Bolts

- Fastener Torque

- Aircraft Rivets