Aircraft nuts can be divided into two general groups: non-self-locking and self-locking nuts. Non-self-locking nuts are those that must be safetied by external locking devices, such as cotter pins, safety wire, or locknuts. Self-locking nuts contain the locking feature as an integral part.

Non-Self-Locking Nuts

Most of the familiar types of nuts, including the plain nut, the castle nut, the castellated shear nut, the plain hex nut, the light hex nut, and the plain check nut are the non-self-locking type. [Figure 1] |

| Figure 1. Non-self-locking nuts |

The castle nut, AN310, is used with drilled shank AN hex head bolts, Clevis bolts, eyebolts, drilled head bolts, or studs. It is rugged and can withstand large tensional loads. Slots (called castellations) in the nut are designed to accommodate a cotter pin or lock wire for safety.

The castellated shear nut, AN320, is designed for use with devices, such as drilled Clevis bolts and threaded taper pins, which are normally subjected to shearing stress only. Like the castle nut, it is castellated for safetying. Note, however, that the nut is not as deep or as strong as the castle nut; also, that the castellations are not as deep as those in the castle nut.

The plain hex nut, AN315 and AN335 (fine and coarse thread), is of rugged construction. This makes it suitable for carrying large tensional loads. However, since it requires an auxiliary locking device, such as a check nut or lock washer, its use on aircraft structures is somewhat limited.

The light hex nut, AN340 and AN345 (fine and coarse thread), is a much lighter nut than the plain hex nut and must be locked by an auxiliary device. It is used for miscellaneous light tension requirements.

The plain check nut, AN316, is employed as a locking device for plain nuts, set screws, threaded rod ends, and other devices.

The wing nut, AN350, is intended for use where the desired tightness can be obtained by hand and where the assembly is frequently removed.

[ad-mid]

Self-Locking Nuts

As their name implies, self-locking nuts need no auxiliary means of safetying but have a safetying feature included as an integral part of their construction. Many types of self-locking nuts have been designed and their use has become quite widespread. Common applications are:- Attachment of antifriction bearings and control pulleys

- Attachment of accessories, anchor nuts around inspection holes, and small tank installation openings

- Attachment of rocker box covers and exhaust stacks

Self-locking nuts are acceptable for use on certificated aircraft subject to the restrictions of the manufacturer. Self-locking nuts are used on aircraft to provide tight connections that do not shake loose under severe vibration. Do not use self-locking nuts at joints, which subject either the nut or bolt to rotation. They may be used with antifriction bearings and control pulleys, provided the inner race of the bearing is clamped to the supporting structure by the nut and bolt. Plates must be attached to the structure in a positive manner to eliminate rotation or misalignment when tightening the bolts or screws.

The two general types of self-locking nuts currently in use are the all-metal type and the fiber lock type. For the sake of simplicity, only three typical kinds of self-locking nuts are considered in this post: the Boots self-locking and the stainless steel self-locking nuts, representing the all-metal types; and the elastic stop nut, representing the fiber insert type.

Boots Self-Locking Nut

The Boots self-locking nut is of one piece, all-metal construction designed to hold tight despite severe vibration. Note in Figure 2 that it has two sections and is essentially two nuts in one: a locking nut and a load-carrying nut. The two sections are connected with a spring, which is an integral part of the nut. |

| Figure 2. Self-locking nuts |

The spring keeps the locking and load-carrying sections such a distance apart that the two sets of threads are out of phase or spaced so that a bolt, which has been screwed through the load-carrying section, must push the locking section outward against the force of the spring to engage the threads of the locking section properly.

The spring, through the medium of the locking section, exerts a constant locking force on the bolt in the same direction as a force that would tighten the nut. In this nut, the load-carrying section has the thread strength of a standard nut of comparable size, while the locking section presses against the threads of the bolt and locks the nut firmly in position. Only a wrench applied to the nut loosens it. The nut can be removed and reused without impairing its efficiency.

Boots self-locking nuts are made with three different spring styles and in various shapes and sizes. The wing type that is the most common ranges in size for No. 6 up to 1⁄4 inch, the Rol-top ranges from 1⁄4 inch to 1⁄6 inch, and the bellows type ranges in size from No. 8 up to 3⁄8 inch. Wing-type nuts are made of anodized aluminum alloy, cadmium-plated carbon steel, or stainless steel. The Rol-top nut is cadmium-plated steel, and the bellows type is made of aluminum alloy only.

Stainless Steel Self-Locking Nut

The stainless steel self-locking nut may be spun on and off by hand as its locking action takes places only when the nut is seated against a solid surface and tightened. The nut consists of two parts: a case with a beveled locking shoulder and key and a thread insert with a locking shoulder and slotted keyway. Until the nut is tightened, it spins on the bolt easily, because the threaded insert is the proper size for the bolt. However, when the nut is seated against a solid surface and tightened, the locking shoulder of the insert is pulled downward and wedged against the locking shoulder of the case. This action compresses the threaded insert and causes it to clench the bolt tightly. The cross-sectional view in Figure 3 shows how the key of the case fits into the slotted keyway of the insert so that when the case is turned, the threaded insert is turned with it. Note that the slot is wider than the key. This permits the slot to be narrowed and the insert to be compressed when the nut is tightened. |

| Figure 3. Stainless steel self-locking nut |

Elastic Stop Nut

The elastic stop nut is a standard nut with the height increased to accommodate a fiber locking collar. This fiber collar is very tough and durable and is unaffected by immersion in hot or cold water or ordinary solvents, such as ether, carbon tetrachloride, oils, and gasoline. It will not damage bolt threads or plating.As shown in Figure 4, the fiber locking collar is not threaded, and its inside diameter is smaller than the largest diameter of the threaded portion or the outside diameter of a corresponding bolt. When the nut is screwed onto a bolt, it acts as an ordinary nut until the bolt reaches the fiber collar. When the bolt is screwed into the fiber collar, however, friction (or drag) causes the fiber to be pushed upward. This creates a heavy downward pressure on the load carrying part and automatically throws the load carrying sides of the nut and bolt threads into positive contact. After the bolt has been forced all the way through the fiber collar, the downward pressure remains constant. This pressure locks and holds the nut securely in place even under severe vibration.

|

| Figure 4. Elastic stop nut |

Nearly all elastic stop nuts are steel or aluminum alloy. However, such nuts are available in practically any kind of metal. Aluminum-alloy elastic stop nuts are supplied with an anodized finish. Steel nuts are cadmium plated.

Normally, elastic stop nuts can be used many times with complete safety and without detriment to their locking efficiency. When reusing elastic stop nuts, be sure the fiber has not lost its locking friction or become brittle. If a nut can be turned with the fingers, replace it.

After the nut has been tightened, make sure the rounded or chamfered end of the bolts, studs, or screws extends at least the full round or chamfer through the nut. Flat end bolts, studs, or screws should extend at least 1⁄32 inch through the nut. Bolts of 5⁄16-inch diameter and over with cotter pin holes may be used with self-locking nuts, but only if free from burrs around the holes. Bolts with damaged threads and rough ends are not acceptable. Do not tap the fiber locking insert. The self-locking action of the elastic stop nut is the result of having the bolt threads impress themselves into the untapped fiber.

Do not install elastic stop nuts in places where the temperature is higher than 250 °F, because the effectiveness of the self-locking action is reduced beyond this point. Self-locking nuts may be used on aircraft engines and accessories when the engine manufacturer specifies their use.

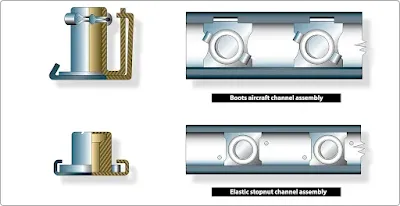

Self-locking nut bases are made in several forms and materials for riveting and welding to aircraft structure or parts. [Figure 5] Certain applications require the installation of self-locking nuts in channels, an arrangement that permits the attachment of many nuts with only a few rivets. These channels are track-like bases with regularly spaced nuts, which are either removable or non-removable. The removable type carries a floating nut that can be snapped in or out of the channel, thus making possible the easy removal of damaged nuts. Nuts, such as the clinch-type and spline-type, depend on friction for their anchorage and are not acceptable for use in aircraft structures.

|

| Figure 5. Self-locking nut bases |

Sheet Spring Nuts

Sheet spring nuts, such as speed nuts, are used with standard and sheet metal self-tapping screws in non-structural locations. They find various uses in supporting line clamps, conduit clamps, electrical equipment, access doors, and the like and are available in several types. Speed nuts are made from spring steel and are arched prior to tightening. This arched spring lock prevents the screw from working loose. These nuts should be used only where originally used in the fabrication of the aircraft.[ad-long]

Internal & External Wrenching Nuts

Two commercial types of high-strength internal or external wrenching nuts are available; they are the internal and external wrenching elastic stop nut and the Unbrako internal and external wrenching nut. Both are of the self-locking type, are heat-treated, and can carry high-strength bolt tension loads.Identification & Coding

Part numbers designate the type of nut. The common types and their respective part numbers are:- Plain, AN315 and AN335

- Castle, AN310

- Plain check, AN316

- Light hex, AN340 and AN345

- Castellated shear, AN320

The patented self-locking types are assigned part numbers ranging from MS20363 through MS20367. The Boots, the Flexloc, the fiber locknut, the elastic stop nut, and the self-locking nut belong to this group. Part number AN350 is assigned to the wing nut.

Letters and digits following the part number indicate such items as material, size, threads per inch, and whether the thread is right or left hand. The letter “B” following the part number indicates the nut material to be brass, a “D” indicates 2017-T aluminum alloy, a “DD” indicates 2024-T aluminum alloy, a “C” indicates stainless steel, and a dash in place of a letter indicates cadmium-plated carbon steel.

The digit (or two digits) following the dash or the material code letter is the dash number of the nut, and it indicates the size of the shank and threads per inch of the bolt on which the nut fits. The dash number corresponds to the first figure appearing in the part number coding of general purpose bolts. A dash and the number 3, for example, indicate that the nut fits an AN3 bolt (10-32); a dash and the number 4 means it fits an AN4 bolt (1⁄4-28); a dash and the number 5, an AN5 bolt (5⁄16-24); and so on.

The code numbers for self-locking nuts end in three or four digit numbers. The last two digits refer to threads per inch, and the one or two preceding digits stand for the nut size in 16ths of an inch.

Some other common nuts and their code numbers are:

Code Number AN310D5R:

AN310 = aircraft castle nut

D = 2024-T aluminum alloy

5 = 5⁄16 inch diameter

R = right-hand thread (usually 24 threads per inch)

Code Number AN320-10:

AN320 = aircraft castellated shear nut, cadmium-plated carbon steel

10 = 5⁄8 inch diameter, 18 threads per inch (this nut is usually right-hand thread)

Code Number AN350B1032:

AN350 = aircraft wing nut

B = brass

10 = number 10 bolt

AN310 = aircraft castle nut

D = 2024-T aluminum alloy

5 = 5⁄16 inch diameter

R = right-hand thread (usually 24 threads per inch)

Code Number AN320-10:

AN320 = aircraft castellated shear nut, cadmium-plated carbon steel

10 = 5⁄8 inch diameter, 18 threads per inch (this nut is usually right-hand thread)

Code Number AN350B1032:

AN350 = aircraft wing nut

B = brass

10 = number 10 bolt

32 = threads per inch

- Aircraft Materials, Hardware, and Processes

- Properties of Metals

- Aircraft Bolt

- Aircraft Washers

- Installation and Safetying of Nuts, Washers, & Bolts

- Fastener Torque

- Aircraft Rivets