The largest weight changes that occur during the lifetime of an aircraft are those caused by alterations and repairs. It is the responsibility of the FAA-certificated mechanic or repairman doing the work to accurately document the weight change and record it in both the maintenance records and the Pilot’s Operating Handbook/Aircraft Flight Manual (POH/AFM).

Equipment List

The Federal Aviation Administration (FAA) considers the addition or removal of equipment included in the Comprehensive Equipment List to be a minor alteration. The weights and arms are included with the items in the equipment list, and these minor alterations can be done and the aircraft approved for return to service by an FAA-certificate mechanic or repairman. The only documentation required is an entry in the aircraft maintenance records and the appropriate change to the weight and balance record in the POH/AFM. [Figure 1]

|

| Figure 1. A typical 14 CFR part 23 weight and balance record |

Figure 2 is a comprehensive list of all Cessna equipment that is available for the Model 182S airplane. It should not be confused with the airplane-specific equipment list. An airplane-specific list is provided with each individual airplane at delivery and is typically found at the end of the Pilot’s Operating Handbook. The following comprehensive equipment list and the airplane-specific list have a similar order of listing.

|

| Figure 2. Typical comprehensive equipment list |

In the Item No column, each item is assigned a coded number. The first two digits of the code represent the assignment of an equipment item within the ATA Specification 100 breakdown (Chapter 11 for Placards, Chapter 21 for Air Conditioning, Chapter 77 for Engine Indicating, etc.). These assignments also correspond to the Maintenance Manual chapter breakdown for the airplane. Items receive a unique sequence number (01, 02, 03, etc.). After the sequence number (and hyphen), a suffix letter is assigned to identify an equipment item as required, standard, or optional. Suffix letters are as follows:

–R = required item or equipment for FAA certification

–S = standard equipment item

–O = optional equipment item replacing required or standard item(s)

–A = optional equipment item that is in addition to required or standard items

In the Equipment List Description column, each item is assigned a descriptive name to help identify its function.

In the Ref Drawing column, a drawing number is provided that corresponds to the item.

Note: Additional equipment must be installed in accordance with the reference drawing, service bulletin, or a separate FAA approval.

In the Wt and Arm columns, you find the weight in pounds and arm in inches of the equipment item.

Notes: Unless otherwise indicated, true values (not net change values) for the weight and arm are shown. Positive arms are distances aft of the airplane datum; negative arms are distances forward of the datum. Asterisks (*) in the weight and arm column indicate complete assembly installations. Some major components of the assembly are listed on the lines immediately following. The sum of these major components does not necessarily equal the complete assembly installation.

Major Alteration and Repair

Within the following text, information concerning major repairs or major alterations does not apply to any aircraft within the light-sport category.

Any major alteration or repair requires the work to be done by an FAA-certificated mechanic or repairman or facility. The work must be checked for conformity to FAA-approved data and signed off by an aircraft mechanic holding an Inspection Authorization (IA) or by an authorized agent of an appropriately rated FAA-approved repair station. A Repair Station record and/or FAA form 337, Major Repair and Alteration, must be completed describing the work. (Reference Title 14 of the Code of Federal Regulations (14 CFR) part 43, appendix B, for the recording of major repair and alterations requirements.) A dated and signed revision to the weight and balance record is made and kept with the maintenance records, and the airplane’s new empty weight and empty weight arm or moment index are entered in the POH/AFM.

Weight and Balance Revision Record

Aircraft manufacturers use different formats for their weight and balance data, but Figure 3 is typical of a weight and balance revision record. All weight and balance records should be kept with the other aircraft records. Each revision record should be identified by the date, the aircraft make, model, and serial number. The pages should be signed by the person making the revision and his or her certificate type and number must be included.

|

| Figure 3. A typical airplane weight and balance revision record |

The computations for a weight and balance revision are included on a weight and balance revision form. Appropriate fore-and-aft extreme loading conditions should be investigated and the computations shown. The date those computations were made is shown in the upper right corner of Figure 3. When this work is superseded, a notation must be made on the new weight and balance revision form, including a statement that the new computations supersede the computations dated “MM/DD/YY.”

The weight and balance revision sheet should clearly show the revised empty weight, empty weight arm and/or moment index, and the new useful load. An example of these entries can be found at the bottom of Figure 3.

Weight Changes Caused by a Repair or Alteration

A typical alteration might consist of removing two pieces of radio equipment from the instrument panel and a power supply that was located in the baggage compartment behind the rear seat. In this example, these two pieces are replaced with a single lightweight, self-contained radio. At the same time, an old emergency locator transmitter (ELT) is removed from its mount near the tail, and a lighter weight unit is installed. A passenger seat is installed in the baggage compartment.

Computations Using Weight, Arm, and Moment

The first step in the weight and balance computation is to make a chart like the one in Figure 4, listing all of the items that are involved. The new center of gravity (CG) of 36.4 inches aft of the datum is determined by dividing the new moment by the new weight.

|

| Figure 4. Weight, arm, and moment changes caused by typical alteration or repair |

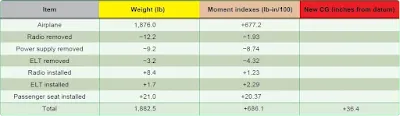

Computations Using Weight and Moment Indexes

If the weight and balance data uses moment indexes rather than arms and moments, this same alteration can be computed using a chart such as the one in Figure 5. Subtract the weight and moment indexes of all the removed equipment from the empty weight and moment index of the airplane. Add the weight and moment indexes of all equipment installed to determine the total weight and the total moment index. To determine the position of the new CG in inches aft of the datum, multiply the total moment index by 100 to get the moment, and divide this by the total weight to get the new CG.

|

| Figure 5. Weight and moment index changes caused by a typical alteration or repair |

Determining the CG in Percentage of Mean Aerodynamic Chord (Percent MAC)

This procedure is the same as found in Single-Engine Aircraft Weight and Balance Computations post. Refer to the load conditions and CG information found in Figures 5, 6, and 7 to compute the CG in percent MAC:

|

| Figure 6. Weight and balance information |

|

| Figure 7. Loading conditions |

The MAC is 58.0 inches long.

The leading edge mean aerodynamic chord (LEMAC) is located at station 25.98.

The CG is +36.4 – 25.98 = 10.42 inches aft of LEMAC.

Use the formula in Figure 8 to determine CG in MAC percentages.

|

| Figure 8. Formula for determining the CG in percent MAC |

The loaded CG after alteration or repair is located at 17.9 percent MAC.

Empty Weight CG (EWCG) Range

The fuel tanks, seats, and baggage compartments of some aircraft are so located that changes in the fuel or occupant load have a very limited effect on the balance of the aircraft. Aircraft of such a configuration show an empty weight CG (EWCG) range in the Type Certificate Data Sheet (TCDS). If the EWCG is located within this range, it is impossible to legally load the aircraft so that its loaded CG falls outside its allowable range.

If the TCDS lists an EWCG range, and after the alteration is completed the EWCG falls within this range, then there is no need to compute a fore and aft check for adverse loading. But if the TCDS lists the EWCG range as “None” (and most of them do), a check must be made to determine whether or not it is possible by any combination of legal loading to cause the aircraft CG to move outside of either its forward or aft limits.

Adverse-Load CG Checks

Many modern aircraft have multiple rows of seats and often more than one baggage compartment. After any repair or alteration that changes the weight and balance, the Airframe and Powerplant (A&P) FAA-certificated mechanic or repairman must ensure that no legal condition of loading can move the CG outside of its allowable limits. To determine this, adverse-loaded CG checks must be performed and the results noted in the weight and balance revision sheet. [Figure 3]

Forward Adverse-Load CG Check

To conduct a forward CG check, make a chart that includes the airplane and any occupants and items of the load located in front of the forward CG limit. Include only those items behind the forward limit that are essential to flight:the pilot, and the minimum fuel.

In this example, the pilot, whose nominal weight is 170 pounds, is behind the forward CG limit. The fuel is also behind the forward limit, so the minimum fuel is used. For weight and balance purposes, the minimum fuel is no more than the quantity needed for one-half hour of operation at rated maximum continuous power. This is considered to be 1⁄12 gallon for each maximum except takeoff (METO) horsepower. Because aviation gasoline weighs 6 pounds per gallon, determine the number of pounds of the minimum fuel by dividing the METO horsepower by two. In this example, minimum fuel is 115 pounds. The front and rear seats and the baggage are all behind the forward CG limit, so no passengers or baggage are considered.

Make a chart like the one in Figure 9 to determine the CG with the aircraft loaded for its most forward CG. With the load consisting of only a pilot and the minimum fuel, the CG is +36.6, which is behind the most forward allowable limit for this weight of +33.0.

|

| Figure 9. Load conditions for forward adverse-load CG check |

Aft Adverse-Load CG Check

To conduct an aft or rearward CG check, make a chart that includes the empty weight and EWCG of the aircraft after the alteration and all occupants and items of the load behind the aft CG limit of 46.0. The pilot is in front of this limit but is essential for flight and must be included. In this example, only the pilot occupies the front seats. Since the CG of the fuel is behind the aft limit, full fuel is used, as well as the nominal weight (170 lb) for both rear seat passengers and the maximum allowable baggage.

Under these loading conditions, the CG is located at +45.8, which is ahead of the aft limit of +46.0. [Figure 10] With only the pilot in front of the aft CG limit and maximum of all items behind the aft limit, the CG is at +45.8 inches, which is ahead of the aft limit of +46.0 inches.

|

| Figure 10. Load conditions for aft adverse-load CG check |

Ballast

It is possible to load most modern airplanes so the CG shifts outside of the allowable limit. Placards and loading instructions in the weight and balance data inform the pilot of the restrictions that prevent such a shift from occurring. A typical placard in the baggage compartment of an airplane is shown in Figure 11. When the CG of an aircraft falls outside of the limits, it can usually be brought back in by using ballast.

|

| Figure 11. Typical baggage compartment placard |

Temporary Ballast

Temporary ballast, in the form of lead bars or heavy canvas bags of sand or lead shot, is often carried in the baggage compartments to adjust the balance for certain flight conditions. The bags are marked “Ballast XX Pounds—Removal Requires Weight and Balance Check.” Temporary ballast must be secured so it cannot shift its location in flight and the structural limits of the baggage compartment must not be exceeded. All temporary ballast must be removed before the aircraft is weighed.

Temporary Ballast Formula

The CG of a loaded airplane can be moved into its allowable range by shifting passengers or cargo or by adding temporary ballast.

Permanent Ballast

If a repair or alteration causes the aircraft CG to fall outside of its limit, permanent ballast can be installed. Usually permanent ballast is made of blocks of lead painted red and marked “Permanent Ballast—Do Not Remove.” It should be attached to the structure so that it does not interfere with any control action and attached rigidly enough that it cannot be dislodged by any flight maneuvers or rough landing.

Two things must first be known to determine the amount of ballast needed to bring the CG within limits: the amount the CG is out of limits, and the distance between the location of the ballast and the limit that is affected.

If an airplane with an empty weight of 1,876 pounds has been altered so its EWCG is +32.2, and CG range for weights up to 2,250 pounds is +33.0 to +46.0, permanent ballast must be installed to move the EWCG from +32.2 to +33.0. There is a bulkhead at fuselage station 228 strong enough to support the ballast.

To determine the amount of ballast needed, use the formula in Figure 12.

|

| Figure 12. Formula for determining ballast |

A block of lead weighing 7.7 pounds, attached to the bulkhead at fuselage station 228, moves the EWCG back to its proper forward limit of +33. This block should be painted red and marked “Permanent Ballast—Do Not Remove.”