Adjusting the Spray Pattern

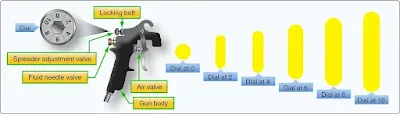

To obtain the correct spray pattern, set the recommended air pressure on the gun, usually 40 to 50 psi for a conventional gun. Test the pattern of the gun by spraying a piece of masking paper taped to the wall. Hold the gun square to the wall approximately 8 to 10 inches from the surface. (With hand spread, it is the distance from the tip of the thumb to the tip of the little finger.)All spray guns (regardless of brand name) have the same type of adjustments. The upper control knob proportions the air flow, adjusting the spray pattern of the gun. [Figure 1]

|

| Figure 1. Adjustable spray pattern |

The lower knob adjusts the fluid passing the needle, which in turn controls the amount or volume of paint being delivered through the gun.

Pull the trigger lever fully back. Move the gun across the paper, and alternately adjust between the two knobs to obtain a spray fan of paint that is wet from top to bottom (somewhat like the pattern at dial 10.) Turning in (to the right) on the lower, or fluid knob, reduces the amount of paint going through the gun. Turning out increases the volume of paint. Turning out (to the left) on the upper, or pattern control knob, widens the spray pattern. Turning in reduces it to a cone shape (as shown with dial set at 0).

Once the pattern is set on the gun, the next step is to follow the correct spraying technique for applying the coating to the surface.

Applying the Finish

If the painter has never used a spray gun to apply a finish coat of paint, and the aircraft has been completely prepared, cleaned, primed, and ready for the topcoat, he or she may need to pause for some practice. Reading a book or an instruction manual is a good start as it provides the basic knowledge about the movement of the spray gun across the surface. Also, if available, the opportunity to observe an aircraft being painted is well worth the time.At this point in the project, the aircraft has already received its primer coats. The difference between the primer and the finish topcoat is that the primer is flat (no gloss) and the finish coat has a glossy surface (some more than others, depending on the paint). The flat finish of the primer is obtained by paying attention to the basics of trigger control distance from the surface and consistent speed of movement of the spray gun across the surface.

Primer is typically applied using a crosscoat spray pattern. A crosscoat is one pass of the gun from left to right, followed by another pass moving up and down. The starting direction does not matter as long as the spraying is accomplished in two perpendicular passes. The primer should be applied in light coats as cross-coating is the application of two coats of primer.

[ad-mid]

Primer does not tend to run because it is applied in light coats. The gloss finish requires a little more experience with the gun. A wetter application produces the gloss, but the movement of the gun, overlap of the spray pattern, and the distance from the surface all affect the final product. It is very easy to vary one or another, yielding runs or dry spots and a less than desirable finish. Practice not only provides some experience, but also provides the confidence needed to produce the desired finish.

Start the practice by spraying the finish coat material on a flat, horizontal panel. The spray pattern has been already adjusted by testing it on the masking paper taped to the wall. Hold the gun 8–10 inches away from and perpendicular to the surface. Pull the trigger enough for air to pass through the cap and start a pass with the gun moving across the panel. As it reaches the point to start painting, squeeze the trigger fully back and continue moving the gun about one foot per second across the panel until the end is reached. Then, release the trigger enough to stop the paint flow but not the air flow. [Figure 2]

Start the practice by spraying the finish coat material on a flat, horizontal panel. The spray pattern has been already adjusted by testing it on the masking paper taped to the wall. Hold the gun 8–10 inches away from and perpendicular to the surface. Pull the trigger enough for air to pass through the cap and start a pass with the gun moving across the panel. As it reaches the point to start painting, squeeze the trigger fully back and continue moving the gun about one foot per second across the panel until the end is reached. Then, release the trigger enough to stop the paint flow but not the air flow. [Figure 2]

The constant air flow through the gun maintains a constant pressure, rather than a buildup of pressure each time that the trigger is released. This would cause a buildup of paint at the end of each pass, causing runs and sags in the finish. Repeat the sequence of the application, moving back in the opposite direction and overlapping the first pass by 50 percent. This is accomplished by aiming the center of the spray pattern at the outer edge of the first pass and continuing the overlap with each successive pass of the gun.

Once the painter has mastered spraying a flat horizontal panel, practice next on a panel that is positioned vertically against a wall. This is the panel that shows the value of applying a light tack coat before spraying on the second coat. The tack coat holds the second coat from sagging and runs. Practice spraying this test panel both horizontally with overlapping passes and then rotate the air cap 90° on the gun and practice spraying vertically with the same 50 percent overlapping passes.

Practice cross-coating the paint for an even application. Apply two light spray passes horizontally, overlapping each by 50 percent, and allowing it to tack. Then, spray vertically with overlapping passes, covering the horizontal sprayed area. When practice results in a smooth, glossy, no-run application on the vertical test panel, you are ready to try your skill on the actual project.

Once the painter has mastered spraying a flat horizontal panel, practice next on a panel that is positioned vertically against a wall. This is the panel that shows the value of applying a light tack coat before spraying on the second coat. The tack coat holds the second coat from sagging and runs. Practice spraying this test panel both horizontally with overlapping passes and then rotate the air cap 90° on the gun and practice spraying vertically with the same 50 percent overlapping passes.

Practice cross-coating the paint for an even application. Apply two light spray passes horizontally, overlapping each by 50 percent, and allowing it to tack. Then, spray vertically with overlapping passes, covering the horizontal sprayed area. When practice results in a smooth, glossy, no-run application on the vertical test panel, you are ready to try your skill on the actual project.

Common Spray Gun Problems

A quick check of the spray pattern can be verified before using the gun by spraying some thinner or reducer, compatible with the finish used, through the gun. It is not of the same viscosity as the coating, but it indicates if the gun is working properly before the project is started.If the gun is not working properly, use the following information to troubleshoot the problem:

- A pulsating, or spitting, fan pattern may be caused by a loose nozzle, clogged vent hole on the supply cup, or the packing may be leaking around the needle.

- If the spray pattern is offset to one side or the other, the air ports in the air cap or the ports in the horns may be plugged.

- If the spray pattern is heavy on the top or the bottom, rotate the air cap 180°. If the pattern reverses, the air cap is the problem. If it stays the same, the fluid tip or needle may be damaged.

- Other spray pattern problems may be a result of improper air pressure, improper reducing of the material, or wrong size spray nozzle.

RELATED POSTS