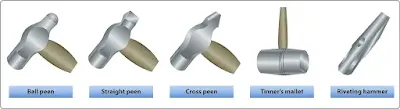

Hammers and Mallets

Figure 1 shows some of the hammers that the aviation mechanic may be required to use. Metal head hammers are usually sized according to the weight of the head alone without the handle. |

| Figure 1. Hammers |

Occasionally, it is necessary to use a soft-faced hammer, which has a striking surface made of wood, brass, lead, rawhide, hard rubber, or plastic. These hammers are intended for use in forming soft metals and striking surfaces that are easily damaged. Soft-faced hammers should not be used for striking punch heads, bolts, or nails, as using one in this fashion quickly ruins this type of hammer.

A mallet is a hammer-like tool with a head made of hickory, rawhide, or rubber. It is handy for shaping thin metal parts without causing creases or dents with abrupt corners. Always use a wooden mallet when pounding a wood chisel or a gouge.

When using a hammer or mallet, choose the one best suited for the job. Ensure that the handle is tight. When striking a blow with the hammer, use the forearm as an extension of the handle. Swing the hammer by bending the elbow, not the wrist. Always strike the work squarely with the full face of the hammer. When striking a metal tool with a metal hammer, the use of safety glasses or goggles is strongly encouraged. Always keep the faces of hammers and mallets smooth and free from dents, chips, or gouges to prevent marring of the work.

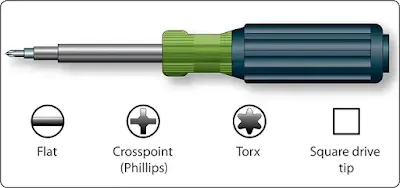

Screwdrivers

The screwdriver can be classified by its shape, type of blade, and blade length. [Figure 2] It is made for only one purpose, loosening or tightening screws or screw head bolts. When using the common screwdriver, select the largest screwdriver whose blade makes a good fit in the screw that needs to be turned. |

| Figure 2. Typical screwdrivers |

A common screwdriver must fill at least 75 percent of the screw slot. If the screwdriver is the wrong size, it cuts and burrs the screw slot, making it unusable. The damage may be so severe that the use of a screw extractor may be required. A screwdriver with the wrong size blade may slip and damage adjacent parts of the structure as well.

The common screwdriver is used only where slotted head screws or fasteners are found on aircraft. An example of a fastener that requires the use of a common screwdriver is the camlock style fastener that is used to secure the cowling on some aircraft.

The two types of recessed head screws for common use are the Phillips and the Reed & Prince. Both the Phillips and Reed & Prince recessed heads are optional on several types of screws. As shown in Figure 2, the Reed & Prince recessed head forms a perfect cross. The screwdriver used with this screw is pointed on the end. Since the Phillips screw has a slightly larger center in the cross, the Phillips screwdriver is blunt on the end. The Phillips screwdriver is not interchangeable with the Reed & Prince. The use of the wrong type of screwdriver results in mutilation of the screwdriver and the screw head. When turning a recessed head screw, use only the proper recessed head screwdriver of the correct size. The most common crosspoint screwdrivers are the Number 1 and Number 2 Phillips. Each of these are designed to be used for specific sized screws. A Number 1 Phillips screwdriver is used on 2, 3, and 4 screws, while a Number 2 Phillips is used for screw sizes 5, 6, 7, 8, and 9.

[ad-mid]

An offset screwdriver may be used when vertical space is limited. Offset screwdrivers are constructed with both ends bent 90° to the shank handle. By using alternate ends, most screws can be seated or loosened even when the swinging space is limited. Offset screwdrivers are made for both standard and recessed head screws. Ratcheting right angle screwdrivers are also available and often prove to be indispensable when working in close quarters.

A screwdriver should not be used for chiseling or prying. Do not use a screwdriver to check an electric circuit since an electric arc will burn the tip and make it ineffective. In some cases, an electric arc may fuse the blade to the unit being checked, creating a short circuit.

When using a screwdriver on a small part, always hold the part in the vise or rest it on a workbench. Do not hold the part in the hand, as the screwdriver may slip and cause serious personal injury.

Replaceable tip screwdrivers, commonly referred to as “10 in 1” screwdrivers, allow for the quick changing of a screwdriver tip and economical replacement of the tip when it becomes worn. A wide variety of screwdriver tips, including flat, crosspoint (Reed & Prince, Phillips), Torx (6-point star-shaped pattern), and square drive tips are available for use with the handles. [Figure 3]

A screwdriver should not be used for chiseling or prying. Do not use a screwdriver to check an electric circuit since an electric arc will burn the tip and make it ineffective. In some cases, an electric arc may fuse the blade to the unit being checked, creating a short circuit.

When using a screwdriver on a small part, always hold the part in the vise or rest it on a workbench. Do not hold the part in the hand, as the screwdriver may slip and cause serious personal injury.

Replaceable tip screwdrivers, commonly referred to as “10 in 1” screwdrivers, allow for the quick changing of a screwdriver tip and economical replacement of the tip when it becomes worn. A wide variety of screwdriver tips, including flat, crosspoint (Reed & Prince, Phillips), Torx (6-point star-shaped pattern), and square drive tips are available for use with the handles. [Figure 3]

|

| Figure 3. Replaceable tip screwdriver |

The cordless hand-held power screwdriver has replaced most automatic or spiral screwdrivers for the removal of multiple screws from an airframe. Care must be exercised when using a power screwdriver. If the slip clutch is set for too high a setting when installing a screw, the screwdriver tip will slip and rotate on top of the screw head, damaging it. The screw should be started by hand to avoid driving the screw into the nut or nut plate in a cross-threaded manner. To avoid damaging the slot or receptacle in the head of the screw, the use of cordless power drills fitted with a removable tip driver to remove or install screws is not recommended, as the drill does not have a slip-clutch installed.

Pliers and Plier-Type Cutting Tools

As shown in Figure 4, the pliers used most frequently in aircraft repair work are the diagonal, needlenose, and duckbill. The size of pliers indicates their overall length, usually ranging from 5 to 12 inches. |

| Figure 4. Pliers |

Roundnose pliers are used to crimp metal. They are not made for heavy work because too much pressure springs the jaws, which are often wrapped to prevent scarring the metal.

Needlenose pliers have half round jaws of varying lengths. They are used to hold objects and make adjustments in tight places.

Duckbill pliers resemble a “duck’s bill” in that the jaws are thin, flat, and have the shape of a duck’s bill. They are used exclusively for twisting safety wire.

Diagonal pliers are usually referred to as diagonals or “dikes.” The diagonal is a short-jawed cutter with a blade set at a slight angle on each jaw. This tool can be used to cut wire, rivets, small screws, and cotter pins, besides being practically indispensable in removing or installing safety wire. The duckbill pliers and the diagonal cutting pliers are used extensively in aviation for the job of safety wiring.

Two important rules for using pliers:

- Do not make pliers work beyond their capacity. The long-nosed variety is especially delicate. It is easy to spring or break them or nick the edges. If this occurs, they are practically useless.

- Do not use pliers to turn nuts. In just a few seconds, a pair of pliers can damage a nut more than years of service.

[ad-long]

Punches

Punches are used to locate centers for drawing circles, to start holes for drilling, to punch holes in sheet metal, to transfer location of holes in patterns, and to remove damaged rivets, pins, or bolts.Solid or hollow punches are the two types generally used. Solid punches are classified according to the shape of their points. Figure 5 shows several types of punches.

|

| Figure 5. Punches |

Prick punches are used to place reference marks on metal. This punch is often used to transfer dimensions from a paper pattern directly on the metal. To do this, first place the paper pattern directly on the metal. Then go over the outline of the pattern with the prick punch, tapping it lightly with a small hammer and making slight indentations on the metal at the major points on the drawing. These indentations can then be used as reference marks for cutting the metal. A prick punch should never be struck a heavy blow with a hammer because it may bend the punch or cause excessive damage to the material being worked.

Large indentations in metal, which are necessary to start a twist drill, are made with a center punch. It should never be struck with enough force to dimple the material around the indentation or to cause the metal to protrude through the other side of the sheet. A center punch has a heavier body than a prick punch and is ground to a point with an angle of about 60°.

The drive punch, which is often called a tapered punch, is used for driving out damaged rivets, pins, and bolts that sometimes bind in holes. The drive punch is therefore made with a flat face instead of a point. The size of the punch is determined by the width of the face, which is usually 1⁄8 inch to 1⁄4 inch.

Pin punches, often called drift punches, are similar to drive punches and are used for the same purposes. The difference between the two is that the sides of a drive punch taper all the way to the face while the pin punch has a straight shank. Pin punches are sized by the diameter of the face, in thirty-seconds of an inch, and range from 1⁄16 to 3⁄8 inch in diameter.

In general practice, a pin or bolt that is to be driven out is usually started and driven with a drive punch until the sides of the punch touch the side of the hole. A pin punch is then used to drive the pin or bolt the rest of the way out of the hole. Stubborn pins may be started by placing a thin piece of scrap copper, brass, or aluminum directly against the pin and then striking it with a hammer until the pin begins to move.

Never use a prick punch or center punch to remove objects from holes because the point of the punch spreads the object and causes it to bind even more.

The transfer punch is usually about 4 inches long. It has a point that tapers and then turns straight for a short distance in order to fit a drill locating hole in a template. The tip has a point similar to that of a prick punch. As its name implies, the transfer punch is used to transfer the location of holes through the template or pattern to the material.

[ad-longer]

Wrenches

The wrenches most often used in aircraft maintenance are classified as open-end, box-end, socket, adjustable, ratcheting and special wrenches. The Allen wrench, although seldom used, is required on one special type of recessed screw. One of the most widely used metals for making wrenches is chrome-vanadium steel. Wrenches made of this metal are almost indestructible. Solid, nonadjustable wrenches with open parallel jaws on one or both ends are known as open-end wrenches. These wrenches may have their jaws parallel to the handle or at an angle up to 90°; most are set at an angle of 15°. The wrenches are designed to fit a nut, bolt head, or other object, which makes it possible to exert a turning action.Box-end wrenches are popular tools because of their usefulness in close quarters. They are called box wrenches since they box, or completely surround, the nut or bolt head. Practically all well-manufactured box-end wrenches are made with 12 points so they can be used in places having as little as 15° swing. In Figure 6, point A on the illustrated double-broached hexagon wrench is nearer the centerline of the head and the wrench handle than point B and also the centerline of nut C. If the wrench is inverted and installed on nut C, point A will be centered over side “Y” instead of side “X.” The centerline of the handle will now be in the dotted line position. It is by reversing (turning the wrench over) the position of the wrench that a 15° arc may be made with the wrench handle.

|

| Figure 6. Box-end wrench use |

Although box-end wrenches are ideal to break loose tight nuts or pull tight nuts tighter, time is lost turning the nut off the bolt once the nut is broken loose. Only when there is sufficient clearance to rotate the wrench in a complete circle can this tedious process be avoided.

After a tight nut is broken loose, it can be completely backed off or unscrewed more quickly with an open-end than with a box-end wrench. In this case, a combination wrench can be used. A combination wrench has a box end on one end and an open-end wrench of the same size on the other.

Another option for removing a nut from a bolt is the ratcheting box-end wrench, which can be swung back and forth to remove the nut or bolt. The box-end, combination, and ratcheting wrenches are shown in Figure 7.

|

| Figure 7. Ratcheting, box-end, and combination wrenches |

A socket wrench is made of two parts: the socket, which is placed over the top of a nut or bolt head; and a handle, which is attached to the socket. Many types of handles, extensions, and attachments are available to make it possible to use socket wrenches in almost any location or position. Sockets are made with either fixed or detachable handles. Socket wrenches with fixed handles are usually furnished as an accessory to a machine. They have a four, six, or twelve-sided recess to fit a nut or bolt head that needs regular adjustment. Sockets with detachable handles usually come in sets and fit several types of handles, such as the T, ratchet, screwdriver grip, and speed handle. Socket wrench handles have a square lug on one end that fits into a square recess in the socket head. The two parts are held together by a light, spring-loaded poppet. Two types of sockets, a set of handles, and an extension bar are shown in Figure 8.

|

| Figure 8. Socket wrench set |

The adjustable wrench is a handy utility tool that has smooth jaws and is designed as an open-end wrench. One jaw is fixed, but the other may be moved by a thumbscrew or spiral screwworm adjustment in the handle. The width of the jaws may be varied from 0 to 1⁄2 inch or more. The angle of the opening to the handle is 221⁄2 degrees on an adjustable wrench. One adjustable wrench does the work of several open-end wrenches. Although versatile, they are not intended to replace the standard open-end, box-end, or socket wrenches. When using any adjustable wrench, always exert the pull on the side of the handle attached to the fixed jaw of the wrench. To minimize the possibility or rounding off the fastener, use care to fit the wrench to the bolt or nut to be turned.

[ad-longest]

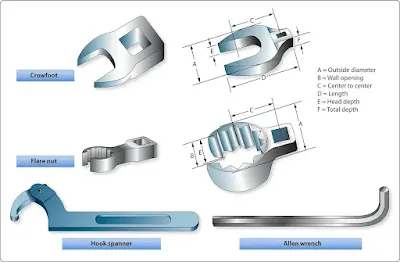

Special Wrenches

The category of special wrenches includes the crowfoot, flare nut, spanner, torque, and Allen wrenches. [Figure 9 and 10] |

| Figure 9. Special wrenches |

|

| Figure 10. Torque wrenches |

The crowfoot wrench is normally used when accessing nuts that must be removed from studs or bolts that cannot be accessed using other tools.

The flare nut wrench has the appearance of a box-end wrench that has been cut open on one end. This opening allows the wrench to be used on the B-nut of a fuel, hydraulic, or oxygen line. Since it mounts using the standard square adapter, like the crowfoot wrench, it can be used in conjunction with a torque wrench.

The hook spanner is for a round nut with a series of notches cut in the outer edge. This wrench has a curved arm with a hook on the end that fits into one of the notches on the nut. The hook is placed in one of these notches with the handle pointing in the direction the nut is to be turned.

Some hook spanner wrenches are adjustable and fit nuts of various diameters. U-shaped hook spanners have two lugs on the face of the wrench to fit notches cut in the face of the nut or screw plug. End spanners resemble a socket wrench, but have a series of lugs that fit into corresponding notches in a nut or plug. Pin spanners have a pin in place of a lug, and the pin fits into a round hole in the edge of a nut. Face pin spanners are similar to the U-shaped hook spanners except that they have pins instead of lugs.

Most headless setscrews are the hex-head Allen type and must be installed and removed with an Allen wrench. Allen wrenches are six-sided bars in the shape of an L, or they can be hex-shaped bars mounted in adapters for use with hand ratchets. They range in size from 3⁄64 to 1⁄2 inch and fit into a hexagonal recess in the setscrew.

[ad-in5]

Torque Wrench

There are times when definite pressure must be applied to a nut or bolt as it is installed. In such cases, a torque wrench must be used. The torque wrench is a precision tool consisting of a torque indicating handle and appropriate adapter or attachments. It measures the amount of turning or twisting force applied to a nut, bolt, or screw.Before each use, the torque wrench should be visually inspected for damage. If a bent pointer, cracked or broken glass (dial type), or signs of rough handling are found, the wrench must be tested. Torque wrenches must be tested at periodic intervals to ensure accuracy.

Calibrating a torque wrench is the process in which the manufacturers of the torque wrench set ensure a precise torque occurs on a standard and consistent basis. Regular torque wrench calibration ensures repeatable accuracy and adherence to standards. A torque wrench is a precision tool and should be treated and maintained like a delicate measuring instrument. A torque wrench must be properly calibrated and maintained on a preventative maintenance and calibration schedule. In order to maintain accuracy, it is crucial that a torque wrench and other measuring equipment be calibrated regularly. Some wrenches or tools may recommend six (6) month calibration intervals, while others may schedule it at twelve (12) months.

The three most commonly used torque wrenches are the deflecting beam, dial indicating, and micrometer setting types. [Figure 10] When using the deflecting beam and the dial indicating torque wrenches, the torque is read visually on a dial or scale mounted on the handle of the wrench. The micrometer setting torque wrench is preset to the desired torque. When this torque is reached, the operator notices a sharp impulse or breakaway “click.”

Strap Wrenches

The strap wrench can prove to be an invaluable tool for the AMT. By their very nature, aircraft components, such as tubing, pipes, small fittings, and round or irregularly-shaped components, are built to be as light as possible while still retaining enough strength to function properly. The misuse of pliers or other gripping tools can quickly damage these parts. If it is necessary to grip a part to hold it in place, or to rotate it to facilitate removal, consider using a strap wrench that uses a plastic covered fabric strap to grip the part. [Figure 11] |

| Figure 11. Strap wrench |

Impact Drivers

In certain applications, the use of an impact driver may be required. Struck with a mallet, the impact driver uses cam action to impart a high amount of torque in a sharp impact to break loose a stubborn fastener. The drive portion of the impact driver can accept a number of different drive bits and sockets. The use of special bits and sockets specifically manufactured for use with an impact driver is required. [Figure 12] |

| Figure 12. Impact driver |

RELATED POSTS