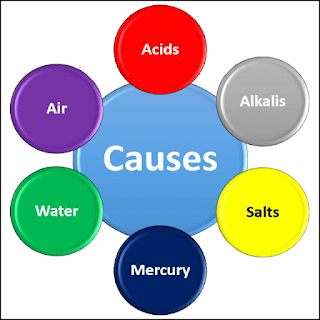

Acids

Moderately strong acids severely corrode most of the alloys used in airframes. The most destructive are sulfuric acid (battery acid), halogen acids (hydrochloric, hydrofluoric, and hydrobromic), nitrous oxide compounds, and organic acids found in the wastes of humans and animals.

Alkalies

As a group, alkalies are not as corrosive as acids. Aluminum and magnesium alloys are exceedingly prone to corrosive attack by many alkaline solutions unless the solutions contain a corrosion inhibitor. Substances particularly corrosive to aluminum are washing soda, potash (wood ashes), and lime (cement dust). Ammonia, an alkali, is an exception because aluminum alloys are highly resistant to it.

Salts

Most salt solutions are good electrolytes and can promote corrosive attack. Some stainless-steel alloys are resistant to attack by salt solutions but aluminum alloy, magnesium alloys, and other steels are extremely vulnerable. Exposure of airframe materials to salts or their solutions is extremely undesirable.

Atmosphere

The major atmospheric corrosive agents are oxygen and airborne moisture. Corrosion often results from the direct action of atmospheric oxygen and moisture on metal, and the presence of additional moisture often accelerates corrosive attack, particularly on ferrous alloys. However, the atmosphere may also contain other corrosive gases and contaminants, particularly industrial and marine salt spray.

Water

Pure water reacts with metals to form corrosion or oxidation, but water holding a concentration of salts or other contaminants causes much more rapid corrosion. Seaplanes are in a continual battle with the elements, and every precaution must be taken to stay ahead of corrosion formation.

Seaplanes operating in salt water are especially vulnerable to attack, and when one is taken out of salt water it should be hosed down with large volumes of fresh water to get every trace of salt off the structure. Seaplane ramps are often located in areas where there is a concentration of industrial wastes, making the water even more corrosive.

Float bottoms are subject to the abrasive effect of high-velocity water on takeoff and landings. Since this abrasion tends to damage the natural protective oxide film, seaplanes must be carefully inspected to detect any damage which would allow water to get to the base metal of the structure.

Mercury

Although it is not commonly found in any quantity around aircraft, there is a definite possibility that mercury could be spilled in an aircraft. Hazardous cargos are often carried in aircraft, and damage from a shifting load can result in damaged containers and hazardous spills.

Mercury attacks aluminum by a chemical reaction known as amalgamation. In this process, the mercury attacks along the grain boundaries within the alloy, and in a very short time completely destroys it.

Extreme care must be exercised when removing spilled mercury, as it is " slippery" and flows through tiny cracks to get to the lowest part of the structure where it causes extensive damage. In addition, mercury and its vapors are poisonous to humans and precautions must be taken to avoid exposure to it. If mercury is spilled, remove every particle with a vacuum cleaner having a mercury trap in the suction line, or with a rubber suction bulb or medicine dropper. Never attempt to remove mercury by blowing it with compressed air. This only scatters it and spreads the damage.