Datum

The datum is an imaginary vertical plane from which all horizontal measurements are taken for balance purposes, with the aircraft in level flight attitude. If the datum is viewed on a drawing of an aircraft, it would appear as a vertical line that is perpendicular (90 degrees) to the aircraft’s longitudinal axis. For each aircraft make and model, the location of all items is identified in reference to the datum. For example, the fuel in a tank might be 60 inches (60") behind the datum, and a radio on the flight deck might be 90" forward of the datum.

The datum is determined by the manufacturer; it is often the leading edge of the wing or some specific distance from an easily identified location. Typical locations for the datum are the aircraft nose, the leading edge of the wing, the helicopter’s mast, or a specified distance from a known point. However, most modern helicopters, like airplanes, have the datum located at the nose of the aircraft or a specified distance ahead of it. Figure 1 shows an aircraft with the leading edge of the wing being the datum. The distance from this datum is measured in inches and can be either positive or negative depending upon where the equipment is located in relation to the datum.

The location of the datum is identified in the Aircraft Specifications or Type Certificate Data Sheet (TCDS). Aircraft certified prior to 1958 fell under the Civil Aeronautics Administration and had their weight and balance information contained in a document known as Aircraft Specifications. Aircraft certified since 1958 fall under the FAA and have their weight and balance information contained in a document known as a Type Certificate Data Sheet (TCDS). The Aircraft Specifications typically included the aircraft equipment list. For aircraft with a TCDS, the equipment list is a separate document.

Arm

The arm is the horizontal distance from the datum to any point within the aircraft. The arm’s distance is always measured in inches, and it is preceded by the algebraic sign for positive (+) or negative (−), except for a location which might be exactly on the datum. The positive sign indicates an item is located aft of the datum, and the negative sign indicates an item is located forward of the datum. If the manufacturer chooses a datum that is at the most forward location on an aircraft, all the arms will be positive numbers. Location of the datum at any other point on the aircraft results in some arms being positive numbers, or aft of the datum, and some arms being negative numbers, or forward of the datum. Figure 1 shows an aircraft where the datum is the leading edge of the wing. For this aircraft, any item (fuel, seat, radio, etc.) located forward of the wing leading edge has a negative arm, and any item located aft of the wing leading edge has a positive arm. If an item is located exactly at the wing leading edge, its arm would be zero, and mathematically it would not matter whether its arm was positive or negative.

The arm of each item is usually included in parentheses immediately after the item’s name or weight in the Aircraft Specifications, TCDS, or equipment list for the aircraft. For example, in a TCDS, the fuel quantity might be identified as 98 gallons (gal) (+93.6) and the forward baggage limit as 100 pounds (lb) (–22.5). These numbers indicate that the fuel is located 93.6" forward of the datum and the nose baggage is located 22.6" aft of the datum. If the arm for a piece of equipment is not known, its exact location must be accurately measured. When the arm for a piece of equipment is being determined, the measurement is taken from the datum to the piece of equipment’s own CG.

[ad-mid]

Moment

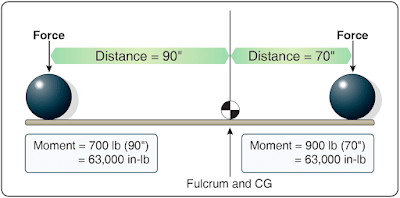

To understand balance, it is necessary to have a working knowledge of the principle of moments. For those unfamiliar with weight and balance terms, the word moment is the product of a force or weight times a distance. The distance used in calculating a moment is referred to as the arm or moment arm and is usually expressed in inches. To calculate a moment, a force (or weight) and a distance must be known. The weight is multiplied by the distance from the datum and the result is the moment, which is expressed in inch-pounds (in-lb), a point through which the force acts. For the purpose of illustration, compare an aircraft to a seesaw. Like the seesaw, for an aircraft to be in balance, or equilibrium, the sum of the moments on each side of the balance point must be equal. Therefore, the same weight that is different distances (in inches) from the datum have greater moments.

A 5 lb radio located 80" from the datum would have a moment of 400 in-lb (5 lb × 80"). A 10-pound radio located 12" from the datum would have a moment of 120 in-lb. Whether the moment is preceded by a positive (+) or negative (−) sign depends on its location in relation to the datum. Figure 2 shows where the moment ends up being a positive number because the weight and arm are both positive.

The algebraic sign of the moment, based on the datum location and whether weight is being installed or removed [Figure 3], would be as follows:

- Weight being added aft of the datum produces a positive moment (+weight, +arm).

- Weight being added forward of the datum produces a negative moment (+weight, −arm).

- Weight being removed aft of the datum produces a negative moment (−weight, +arm).

- Weight being removed forward of the datum produces a positive moment (−weight, −arm).

When dealing with positive and negative numbers, remember that the product of like signs produces a positive answer, and the product of unlike signs produces a negative answer.

Center of Gravity (CG)

The CG is the point at which all the weight of the aircraft is concentrated and balanced; therefore, the aircraft can be supported at that point (the CG). The magnitude of the nose-heavy and tail-heavy moments are exactly equal. It is the balance point for the aircraft and, if suspended from this point, there would be no tendency to rotate in a nose-up or nose-down attitude.

Figure 4 shows a lever with the pivot point (called a fulcrum) located at the CG for the lever. Even though the weights on either side of the fulcrum are not equal, and the distances from each weight to the fulcrum are not equal, the product of the weights and arms (moments) are equal, and that is what produces a balanced condition. Therefore, the lever would be balanced much like two persons sitting on a seesaw who are differing weights and located at different distances from the fulcrum.

Maximum Weight

The maximum weight is the maximum authorized weight of the aircraft and its contents, and is indicated in the Aircraft Specifications or TCDS. For many aircraft, there are variations to the maximum allowable weight depending on the purpose and conditions under which the aircraft is to be flown. For example, a certain aircraft may be allowed a maximum gross weight of 2,750 lb when flown in the normal category, but when flown in the utility category, which allows for limited aerobatics, the same aircraft’s maximum allowable gross weight might only be 2,175 lb. There are other variations when dealing with the concept of maximum weight, as follows:

- Maximum Ramp Weight—the heaviest weight to which an aircraft can be loaded while it is sitting on the ground. This is sometimes referred to as the maximum taxi weight.

- Maximum Takeoff Weight—the heaviest weight an aircraft can be when it starts the takeoff roll. The difference between this weight and the maximum ramp weight would equal the weight of the fuel that would be consumed prior to takeoff.

- Maximum Landing Weight—the heaviest weight an aircraft can be when it lands. For large, wide body commercial airplanes, it can be 100,000 lb less than maximum takeoff weight, or even more.

- Maximum Zero Fuel Weight—the heaviest weight an aircraft can be loaded to without having any usable fuel in the fuel tanks. Any weight loaded above this value must be in the form of fuel.

[ad-long]

RELATED POSTS

Empty Weight

The empty weight of an aircraft includes all operating equipment that has a fixed location and is actually installed in the aircraft. It includes the weight of the airframe, powerplant, required equipment, optional or special equipment, fixed ballast, hydraulic fluid, and residual fuel and oil. Residual fuel and oil are the fluids that do not normally drain out because they are trapped in the fuel lines, oil lines, and tanks. They must be included in the aircraft’s empty weight. For most aircraft certified after 1978, the full capacity of the engine oil system is also included in the empty weight. Information regarding residual fluids in aircraft systems that must be included in the empty weight, and whether or not full oil is included, will be indicated in the Aircraft Specifications or TCDS.

Other terms that are used when describing empty weight include basic empty weight, licensed empty weight, and standard empty weight. The term “basic empty weight” applies when the full capacity of the engine oil system is included in the value. The term “licensed empty weight” applies when only the weight of residual oil is included in the value, so it generally involves only aircraft certified prior to 1978. Standard empty weight would be a value supplied by the aircraft manufacturer, and it would not include any optional equipment that might be installed in an aircraft. For most people working in the aviation maintenance field, the basic empty weight of the aircraft is the most important one.

Empty Weight Center of Gravity (EWCG)

The EWCG for an aircraft is the point at which it balances when it is in an empty weight condition. The concepts of empty weight and CG were discussed earlier in this article, and now they are being combined into a single concept.

One of the most important reasons for weighing an aircraft is to determine its EWCG. All other weight and balance calculations, including loading the aircraft for flight, performing an equipment change calculation, and performing an adverse condition check, begin with knowing the empty weight and EWCG. This crucial information is part of what is contained in the aircraft weight and balance report.

Useful Load

To determine the useful load of an aircraft, subtract the empty weight from the maximum allowable gross weight. For aircraft certificated in both normal and utility categories, there may be two useful loads listed in the aircraft weight and balance records. An aircraft with an empty weight of 3,100 lb may have a useful load of 850 lb, if the normal category maximum weight is listed as 3,950 lb. When the aircraft is operated in the utility category, the maximum gross weight may be reduced to 3,700 lb, with a corresponding decrease in the useful load to 600 lb. Some aircraft have the same useful load regardless of the category in which they are certificated.

The useful load consists of fuel, any other fluids that are not part of empty weight, passengers, baggage, pilot, copilot, and crewmembers. Whether the weight of engine oil is considered part of the useful load depends on when the aircraft was certificated and can be determined by looking at the Aircraft Specifications or TCDS. The payload of an aircraft is like the useful load, except it does not include fuel.

A reduction in the weight of an item, where possible, may be necessary to remain within the maximum weight allowed for the category in which an aircraft is operating. Determining the distribution of these weights is called a weight check.

Minimum Fuel

Many modern aircraft have multiple rows of seats and often more than one baggage compartment. The weight and balance extreme conditions represent the maximum forward and rearward CG position for the aircraft. An aircraft has certain fixed points, fore and aft, beyond which the CG should not be permitted at any time during flight. A check should be made to ensure that the CG will not shift out of limits when crew, passengers, cargo, and expendable weights are added or removed. If the limits are exceeded and the aircraft is flown in this condition, it may lead to insufficient stability, with resulting difficulty in controlling the aircraft. After any repair or alteration that changes the weight and balance, the Airframe and Powerplant (A&P) mechanic or repairman must ensure that no legal condition of loading can move the CG outside of its allowable limits. To determine this, the mechanic will deliberately attempt to calculate the aircraft loading in such a manner as to place the CG outside the limits of the aircraft. This is called an adverse-loading check.

For example, in a forward adverse-loaded CG check, all useful load in front of the forward CG limit is loaded, and all useful load behind this limit is left empty. An exception to leaving it empty is the fuel tank. If the fuel tank is located behind the forward CG limit, it cannot be left empty because the aircraft cannot fly without fuel. In this case, an amount of fuel is accounted for, which is known as minimum fuel. Minimum fuel is the amount needed for 30 minutes of flight at cruise power.

For weight and balance purposes, the minimum fuel is no more than the quantity needed for one half hour of operation at rated maximum continuous power. This is 1⁄12 gallon for each maximum except takeoff (METO) horsepower (Hp). Because aviation gasoline (Avgas) weighs 6 pounds per gallon (lb/gal), determine the number of pounds of the minimum fuel by dividing the METO Hp by 2. For instance, an aircraft having a METO Hp of 200 Hp will have a minimum fuel of 16.65 gallons or 99.99 pounds. An even simpler way is to take the METO Hp divided by 2, which is 100 pounds. Both methods in determining minimum fuel are valued and result in essentially the same answer. In the latter computation, a piston engine in cruise flight burns 1 lb of fuel per hour for each Hp, or 1⁄2 lb for 30 minutes, hence dividing the METO by 2.

For example, if a forward adverse-loaded CG check was performed on a piston engine aircraft, with the engine having a METO Hp of 200, the minimum fuel would be 100 lb (200 METO Hp ÷ 2).

For turbine engine-powered aircraft, minimum fuel is not based on engine Hp. If an adverse-loaded CG check is being performed on a turbine engine-powered aircraft, the aircraft manufacturer would need to supply information on minimum fuel.

Tare Weight

When aircraft are placed on scales and weighed, it is sometimes necessary to use support equipment to aid in the weighing process. For example, to weigh a tail dragger airplane, it is necessary to raise the tail to get the airplane level. To level the airplane, a jack might be placed on the scale and used to raise the tail. Unfortunately, the scale is now absorbing the weight of the jack in addition to the weight of the airplane. This extra weight is known as tare weight and must be subtracted from the scale reading. Other examples of tare weight are wheel chocks placed on the scales and ground locks left in place on retractable landing gear.