The quantity of fuel supplied must be adjusted automatically to correct for changes in ambient temperature or pressure. If the quantity of fuel becomes excessive in relation to mass airflow through the engine, the limiting temperature of the turbine blades can be exceeded, or it will produce compressor stall and a condition referred to as rich blowout. Rich blowout occurs when the amount of oxygen in the air supply is insufficient to support combustion and when the mixture is cooled below the combustion temperature by the excess fuel. The other extreme, lean flame-out, occurs if the fuel quantity is reduced proportionally below the air quantity. The engine must operate through acceleration and deceleration without any fuel-control-related problems.

The fuel system must deliver fuel to the combustion chambers not only in the right quantity, but also in the right condition for satisfactory combustion. The fuel nozzles form part of the fuel system and atomize or vaporize the fuel so that it ignites and burns efficiently. The fuel system must also supply fuel so that the engine can be easily started on the ground and in the air. This means that the fuel must be injected into the combustion chambers in a combustible condition during engine starting, and that combustion must be sustained while the engine is accelerating to its normal idling speed. Another critical condition to which the fuel system must respond occurs during a rapid acceleration. When the engine is accelerated, energy must be furnished to the turbine in excess of that necessary to maintain a constant rpm. However, if the fuel flow increases too rapidly, an over rich mixture can be produced, with the possibility of a rich blowout or compressor stall.

Turbofan, turbojet, turboshaft, and turboprop engines are equipped with a fuel control unit which automatically satisfies the requirements of the engine. Although the basic requirements apply generally to all gas turbine engines, the way in which individual fuel controls meet these needs cannot be conveniently generalized.

[ad-mid]

Turbine Fuel Controls

Gas turbine engine fuel controls can be divided into three basic groups:- Hydromechanical

- Hydromechanical/electronic

- Full Authority Digital Engine (or Electronics) Control (FADEC)

The hydromechanical/electronic fuel control is a hybrid of the two types of fuel control but can function solely as a hydromechanical control. In the dual mode, inputs and outputs are electronic, and fuel flow is set by servo motors. The third type, FADEC, uses electronic sensors for its inputs and controls fuel flow with electronic outputs. The FADEC-type control gives the electronic controller (computer) complete control. The computing section of the FADEC system depends completely on sensor inputs to the electronic engine control (EEC) to meter the fuel flow. The fuel metering device meters the fuel using only outputs from the EEC. Most turbine fuel controls are quickly going to the FADEC type of control. This electronically controlled fuel control is very accurate in scheduling fuel by sensing many of the engine parameters.

Regardless of the type, all fuel controls accomplish essentially the same function. That function is to schedule the fuel flow to match the power required by the pilot. Some sense more engine variables than others. The fuel control can sense many different inputs, such as power lever position, engine rpm for each spool, compressor inlet pressure and temperature, burner pressure, compressor discharge pressure, and many more parameters as needed by the specific engine. These variables affect the amount of thrust that an engine produces for a given fuel flow. By sensing these parameters, the fuel control has a clear picture of what is happening in the engine and can adjust fuel flow as needed. Each type of turbine engine has its own specific needs for fuel delivery and control.

Hydromechanical Fuel Control

Hydromechanical fuel controls were used and are still used on many engines, but their use is becoming limited giving way to electronic based controls. Fuel controls have two sections, computing and metering, to provide the correct fuel flow for the engine. A pure hydromechanical fuel control has no electronic interface assisting in computing or metering the fuel flow. It also is generally driven by the gas generator gear train of the engine to sense engine speed. Other mechanical engine parameters that are sensed are compressor discharge pressure, burner pressure, exhaust temperature, and inlet air temperature and pressure. Once the computing section determines the correct amount of fuel flow, the metering section through cams and servo valves delivers the fuel to the engine fuel system. Actual operating procedures for a hydromechanical fuel control is very complicated and still the fuel metering is not as accurate as with an electronic type of interface or control. Electronic controls can receive more inputs with greater accuracy than hydromechanical controls. Early electronic controls used a hydromechanical control with an electronic system added on the system to fine tune the metering of the fuel. This arrangement also used the hydromechanical system as a backup if the electronic system failed. [Figure 1] |

| Figure 1. Fuel control assembly schematic hydomechanical/electronic |

Hydromechanical/Electronic Fuel Control

The addition of the electronic control to the basic hydromechanical fuel control was the next step in the development of turbine engine fuel controls. Generally, this type of system used a remotely located EEC to adjust the fuel flow. A description of a typical system is explained in the following information. The basic function of the engine fuel system is to pressurize the fuel, meter fuel flow, and deliver atomized fuel to the combustion section of the engine. Fuel flow is controlled by a hydromechanical fuel control assembly, which contains a fuel shutoff section and a fuel metering section.This fuel control unit is sometimes mounted on the vane fuel pump assembly. It provides the power lever connection and the fuel shutoff function. The unit provides mechanical overspeed protection for the gas generator spool during normal (automatic mode) engine operation. In automatic mode, the EEC is in control of metering the fuel. In manual mode, the hydromechanical control takes over.

During normal engine operation, a remotely mounted electronic fuel control unit (EFCU) (same as an EEC) performs the functions of thrust setting, speed governing and acceleration, and deceleration limiting through EFCU outputs to the fuel control assembly in response to power lever inputs. In the event of electrical or EFCU failure, or at the option of the pilot, the fuel control assembly functions in manual mode to allow engine operation at reduced power under control of the hydromechanical portion of the controller only.

The total engine fuel and control system consists of the following components and provides the functions as indicated:

1. The vane fuel pump assembly is a fixed displacement fuel pump that provides high pressure fuel to the engine fuel control system. [Figure 2]

The total engine fuel and control system consists of the following components and provides the functions as indicated:

1. The vane fuel pump assembly is a fixed displacement fuel pump that provides high pressure fuel to the engine fuel control system. [Figure 2]

|

| Figure 2. Fuel pump and filter |

2. The filter bypass valve in the fuel pump allows fuel to bypass the fuel filter when the pressure drop across the fuel filter is excessive. An integral differential pressure indicator visually flags an excessive differential pressure condition before bypassing occurs, by extending a pin from the fuel filter bowl. Fuel pump discharge flow in excess of that required by the fuel control assembly is returned from the control to the pump interstage.

3. The hydromechanical fuel control assembly provides the fuel metering function of the EFCU. Fuel is supplied to the fuel control through a 200-micron inlet filter screen and is metered to the engine by the servo-operated metering valve. It is a fuel flow/compressor discharge pressure (Wf/ P3) ratio device that positions the metering valve in response to engine compressor discharge pressure (P3). Fuel pressure differential across the servo valve is maintained by the servo-operated bypass valve in response to commands from the EFCU. [Figure 1] The manual mode solenoid valve is energized in the automatic mode. The automatic mode restricts operation of the mechanical speed governor. It is restricted to a single overspeed governor setting above the speed range controlled electronically. Deenergizing the manual mode valve enables the mechanical speed governor to function as an all speed governor in response to power lever angle (PLA). The fuel control system includes a low power sensitive torque motor which may be activated to increase or decrease fuel flow in the automatic mode (EFCU mode). The torque motor provides an interface to an electronic control unit that senses various engine and ambient parameters and activates the torque motor to meter fuel flow accordingly. This torque motor provides electromechanical conversion of an electrical signal from the EFCU. The torque motor current is zero in the manual mode, which establishes a fixed Wf/P3 ratio.

This fixed Wf/P3 ratio is such that the engine operates surge free and is capable of producing a minimum of 90 percent thrust up to 30,000 feet for this example system. All speed governing of the high-pressure spool (gas generator) is achieved by the counterweight governor. The counterweight governor modulates a pneumatic servo, consistent with the speed set point as determined by the power lever angle (PLA) setting. The pneumatic servo accomplishes Wf/P3 ratio modulation to govern the gas generator speed by bleeding down the P3 acting on the metering valve servo. The P3 limiter valve bleeds down the P3 pressure acting in the metering valve servo when engine structural limits are encountered in either control mode. The start fuel enrichment solenoid valve provides additional fuel flow in parallel with the metering valve when required for engine cold starting or altitude restarts. The valve is energized by the EFCU when enrichment is required. It is always deenergized in the manual mode to prevent high altitude sub-idle operation. Located downstream of the metering valve are the manual shutoff and pressurizing valves. The shutoff valve is a rotary unit connected to the power lever. It allows the pilot to direct fuel to the engine manually. The pressurizing valve acts as a discharge restrictor to the hydromechanical control. It functions to maintain minimum operating pressures throughout the control. The pressurizing valve also provides a positive leak-tight fuel shutoff to the engine fuel nozzles when the manual valve is closed.

This fixed Wf/P3 ratio is such that the engine operates surge free and is capable of producing a minimum of 90 percent thrust up to 30,000 feet for this example system. All speed governing of the high-pressure spool (gas generator) is achieved by the counterweight governor. The counterweight governor modulates a pneumatic servo, consistent with the speed set point as determined by the power lever angle (PLA) setting. The pneumatic servo accomplishes Wf/P3 ratio modulation to govern the gas generator speed by bleeding down the P3 acting on the metering valve servo. The P3 limiter valve bleeds down the P3 pressure acting in the metering valve servo when engine structural limits are encountered in either control mode. The start fuel enrichment solenoid valve provides additional fuel flow in parallel with the metering valve when required for engine cold starting or altitude restarts. The valve is energized by the EFCU when enrichment is required. It is always deenergized in the manual mode to prevent high altitude sub-idle operation. Located downstream of the metering valve are the manual shutoff and pressurizing valves. The shutoff valve is a rotary unit connected to the power lever. It allows the pilot to direct fuel to the engine manually. The pressurizing valve acts as a discharge restrictor to the hydromechanical control. It functions to maintain minimum operating pressures throughout the control. The pressurizing valve also provides a positive leak-tight fuel shutoff to the engine fuel nozzles when the manual valve is closed.

4. The flow divider and drain valve assembly proportions fuel to the engine primary and secondary fuel nozzles. It drains the nozzles and manifolds at engine shutdown. It also incorporates an integral solenoid for modifying the fuel flow for cold-starting conditions.

During an engine start, the flow divider directs all flow through the primary nozzles. After start, as the engine fuel demand increases, the flow divider valve opens to allow the secondary nozzles to function. During all steady-state engine operation, both primary and secondary nozzles are flowing fuel. A 74-micron, self-bypassing screen is located under the fuel inlet fitting and provides last chance filtration of the fuel prior to the fuel nozzles.

5. The fuel manifold assembly is a matched set consisting of both primary and secondary manifolds and the fuel nozzle assemblies.

Twelve fuel nozzles direct primary and secondary fuel through the nozzles causing the fuel to swirl and form a finely atomized spray. The manifold assembly provides fuel routing and atomizing to ensure proper combustion.

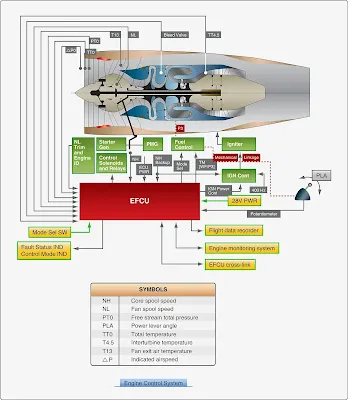

The EEC system consists of the hydromechanical fuel control, EFCU, and aircraft mounted power lever angle potentiometer. Aircraft-generated control signals include inlet pressure, airstream differential pressure, and inlet temperature plus pilot selection of either manual or auto mode for the EFCU operation. Engine-generated control signals include fan spool speed, gas generator spool speed, inner turbine temperature, fan discharge temperature, and compressor discharge pressure. Aircraft- and engine-generated control signals are directed to the EFCU where these signals are interpreted. The PLA potentiometer is aircraft mounted in the throttle quadrant. The PLA potentiometer transmits an electrical signal to the EFCU, which represents engine thrust demand in relation to throttle position. If the EFCU determines a power change is required, it commands the torque motor to modulate differential pressure at the head sensor. This change in differential pressure causes the metering valve to move, varying fuel flow to the engine as required. The EFCU receives electrical signals which represent engine operating variables. It also receives a pilot-initiated signal (by power-lever position) representing engine thrust demand. The EFCU computes electrical output signals for use by the engine fuel control for scheduling engine operation within predetermined limits. The EFCU is programmed to recognize predetermined engine operating limits and to compute output signals such that these operating limits are not exceeded. The EFCU is remotely located and airframe mounted. An interface between the EFCU and aircraft/engine is provided through the branched wiring harness assembly. [Figure 3]

|

| Figure 3. Engine control system |

FADEC Fuel Control Systems

A full authority digital electronic control (FADEC) has been developed to control fuel flow on most new turbine engine models. A true FADEC system has no hydromechanical fuel control backup system. The system uses electronic sensors that feed engine parameter information into the EEC. The EEC gathers the needed information to determine the amount of fuel flow and transmits it to a fuel metering valve. The fuel metering valve simply reacts to the commands from the EEC. The EEC is a computer that is the computing section of the fuel delivery system and the metering valve meters the fuel flow. FADEC systems are used on many types of turbine engines from APUs to the largest propulsion engines.[ad-longer]

FADEC for an Auxiliary Power Unit

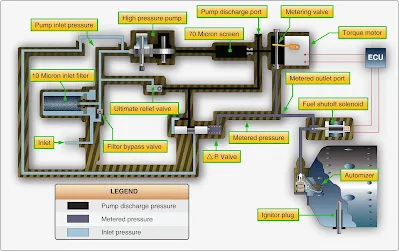

An APU engine uses the aircraft fuel system to supply fuel to the fuel control. An electric boost pump may be used to supply fuel under pressure to the control. The fuel usually passes through an aircraft shutoff valve that is tied to the fire detecting/extinguishing system. An aircraft furnished in-line fuel filter may also be used. Fuel entering the fuel control unit first passes through a 10-micron filter. If the filter becomes contaminated, the resulting pressure drop opens the filter bypass valve and unfiltered fuel then is supplied to the APU. Shown in Figure 4 is a pump with an inlet pressure access plug so that a fuel pressure gauge might be installed for troubleshooting purposes. Fuel then enters a positive displacement, gear-type pump. Upon discharge from the pump, the fuel passes through a 70-micron screen. The screen is installed at this point to filter any wear debris that might be discharged from the pump element. From the screen, fuel branches to the metering valve, differential pressure valve, and the ultimate relief valve. Also shown at this point is a pump discharge pressure access plug, another point where a pressure gauge might be installed. |

| Figure 4. APU fuel system schematic |

The differential pressure valve maintains a constant pressure drop across the metering valve by bypassing fuel to the pump inlet so that metered flow is proportional to metering valve area. The metering valve area is modulated by the torque motor, which receives variable current from the ECU. The ultimate relief valve opens to bypass excess fuel back to the pump inlet whenever system pressure exceeds a predetermined pressure. This occurs during each shutdown since all flow is stopped by the shutoff valve and the differential pressure valve, is unable to bypass full pump capacity. Fuel flows from the metering valve out of the FCU, through the solenoid shutoff valve and on to the atomizer. Initial flow is through the primary nozzle tip only. The flow divider opens at higher pressure and adds flow through the secondary path.

FADEC Fuel Control Propulsion Engine

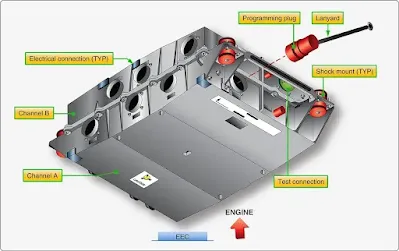

Many large high-bypass turbofan engines use the FADEC type of fuel control system. The EEC is the primary component of the FADEC engine fuel control system. The EEC is a computer that controls the operation of the engine. The EEC housing contains two electronic channels (two separate computers) that are physically separated internally and is naturally cooled by convection. The EEC is generally placed in an area of the engine nacelle that is cool during engine operation. It attaches to the lower-left fan case with shock mounts. [Figure 5] |

| Figure 5. EEC and programming plug |

The EEC computer uses data it receives from many engine sensors and airplane systems to control the engine operation. It receives electronic signals from the flight deck to set engine power or thrust. The throttle lever angle resolver supplies the EEC with a signal in proportion to the thrust lever position. The EEC controls most engine components and receives feedback from them. Many components supply the EEC with data for engine operation.

Power for the EEC comes from the aircraft electrical system or the permanent magnet alternator (PMA). When the engine is running, the PMA supplies power to the EEC directly. The EEC is a two channel computer that controls every aspect of engine operation. Each channel, which is an independent computer, can completely control the operation of the engine. The processor does all of the control calculations and supplies all the data for the control signals for the torque motors and solenoids. The cross-talk logic compares data from channels A and B and uses the cross-talk logic to find which EEC channel is the best to control the output driver for a torque motor or solenoid bank. The primary channel controls all of the output drivers. If the cross-talk logic finds that the other channel is better for control of a specific bank, the EEC changes control of that one bank to the other channel. The EEC has output driver banks that supply the control signals to engine components. Each channel of the EEC supplies the driver banks with control signals. The EEC has both volatile and nonvolatile memory to store performance and maintenance data.

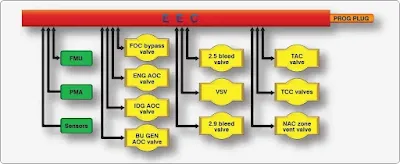

The EEC can control the engine thrust in two modes, which can be selected by use of a mode selection switch. In the normal mode, engine thrust is set with EPR; in the alternate mode, thrust is set by N1. When the fuel control switch is moved from run to cutoff, the EEC resets. During this reset, all fault data is recorded in the nonvolatile memory. The EEC controls the metering valve in the fuel metering unit to supply fuel flow for combustion. [Figure 6] The fuel metering unit is mounted on the front face of the gearbox and is attached to the front of the fuel pump. [Figure 7] The EEC also sends a signal to the minimum pressure and shutoff valve in the fuel metering unit to start or stop fuel flow. The EEC receives position feedback for several engine components by using rotary differential transformer, linear variable differential transformer, and thermocouples. These sensors feed engine parameter information from several systems back to the EEC. The fuel control run cutoff switch controls the high pressure fuel shut off valve that allows or cuts off fuel flow. The fuel temperature sensor thermocouple attaches to the fuel outlet line on the rear of the fuel/oil cooler and sends this information to the EEC. The EEC uses a torque motor driver to control the position of the metering valve in the fuel metering unit. The EEC uses solenoid drivers to control the other functions of the FMU. The EEC also controls several other subsystems of the engine, as shown in Figure 8, through torque motors and solenoids, such as fuel and air oil coolers, bleed valves, variable stator vanes, turbine cooling air valves, and the turbine case cooling system.

|

| Figure 6. Fuel metering unit |

|

| Figure 7. Fuel pump |

|

| Figure 8. Systems controlled by EEC |

Each channel of the EEC has seven electrical connections, three on each side and one on the bottom. Both channels share the inputs of the two connections on the top of the EEC. These are the programming plug and test connector. The programming plug selects the proper software in the EEC for the thrust rating of the engine. The plug attaches to the engine fan case with a lanyard. When removing the EEC, the plug remains with the engine. Each channel of the EEC has three pneumatic connections on the bottom of the EEC. Transducers inside the EEC supply the related and opposite EEC channel with a signal in proportion to the pressure. The pressures that are read by the EEC are ambient pressure, burner pressure, LPC exit pressure, and fan inlet pressure. Each channel has its own wire color that connects the EEC to its sensors. Channel A wiring is blue and channel B sensor signals are green. The non-EEC circuit wire is gray while the thermocouple signals are yellow. This color coding helps simplify which sensors are used with each channel.

[ad-longest]

Fuel System Operation

The fuel pump receives fuel from the airplane fuel system. The low pressure boost stage of the pump pressurizes the fuel and sends it to the fuel/oil cooler (FOC). The fuel flows from the FOC, through the fuel pump filter element, and then to the high pressure main stage of the pump. The high pressure main stage increases the fuel pressure and sends it to the fuel metering unit (FMU). It also supplies servo fuel to the servo fuel heater and engine components. Fuel for combustion (metered fuel) goes through the fuel flow transmitter to the distribution valve. [Figure 9] The fuel distribution valve supplies metered fuel to the fuel supply manifolds. [Figure 10] The fuel injectors get the metered fuel from the fuel supply manifolds and spray the fuel into the engine for combustion. [Figure 11] The fuel pump housing contains a disposable fuel filter element. The fuel filter differential pressure switch supplies a signal to the EEC that indicates an almost clogged filter condition. Unfiltered fuel can then bypass the filter element if the element becomes clogged.

|

| Figure 9. Fuel flow transmitter |

|

| Figure 10. Fuel distribution valve |

|

| Figure 11. Fuel manifolds |

RELATED POSTS