Propeller Reduction Gearing

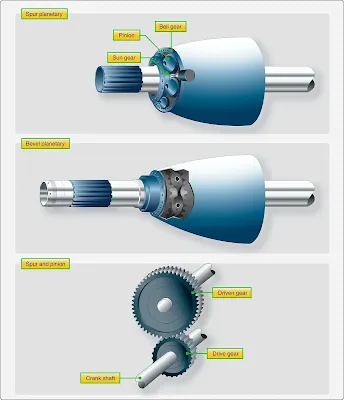

The increased brake horsepower delivered by a high horsepower engine results partly from increased crankshaft rpm. It is therefore necessary to provide reduction gears to limit the propeller rotation speed to a value at which efficient operation is obtained. Whenever the speed of the blade tips approaches the speed of sound, the efficiency of the propeller decreases rapidly. Reduction gearing for engines allows the engine to operate at a higher rpm, developing more power while slowing down the propeller rpm. This prevents the propeller efficiency from decreasing. Since reduction gearing must withstand extremely high stresses, the gears are machined from steel forgings. Many types of reduction gearing systems are in use. The three types most commonly used are spur planetary, bevel planetary, and spur and pinion. [Figure] |

| Reduction gears |

The spur planetary reduction gearing consists of a large driving gear or sun gear splined (and sometimes shrunk) to the crankshaft, a large stationary gear, called a bell gear, and a set of small spur planetary pinion gears mounted on a carrier ring. The ring is fastened to the propeller shaft and the planetary gears mesh with both the sun gear and the stationary bell or ring gear. The stationary gear is bolted or splined to the front section housing. When the engine is operating, the sun gear rotates. Because the planetary gears are meshed with this ring, they also must rotate. Since they also mesh with the stationary gear, they walk or roll around it as they rotate, and the ring in which they are mounted rotates the propeller shaft in the same direction as the crankshaft but at a reduced speed.

In some engines, the bell gear is mounted on the propeller shaft, and the planetary pinion gear cage is held stationary. The sun gear is splined to the crankshaft and acts as a driving gear. In such an arrangement, the propeller travels at a reduced speed but in opposite direction to the crankshaft.

In the bevel planetary reduction gearing system, the driving gear is machined with beveled external teeth and is attached to the crankshaft. A set of mating bevel pinion gears is mounted in a cage attached to the end of the propeller shaft. The pinion gears are driven by the drive gear and walk around the stationary gear, which is bolted or splined to the front section housing. The thrust of the bevel pinion gears is absorbed by a thrust ball bearing of special design. The drive and the fixed gears are generally supported by heavy-duty ball bearings. This type of planetary reduction assembly is more compact than the other one described and, therefore, can be used where a smaller propeller gear step-down is desired. In the case of gas turbine turboprop engines, more than one stage of reduction gearing is used do to the high output speeds of the engine. Several types of lower powered engines can use the spur and pinion reduction gear arrangement.

[ad-mid]

In the bevel planetary reduction gearing system, the driving gear is machined with beveled external teeth and is attached to the crankshaft. A set of mating bevel pinion gears is mounted in a cage attached to the end of the propeller shaft. The pinion gears are driven by the drive gear and walk around the stationary gear, which is bolted or splined to the front section housing. The thrust of the bevel pinion gears is absorbed by a thrust ball bearing of special design. The drive and the fixed gears are generally supported by heavy-duty ball bearings. This type of planetary reduction assembly is more compact than the other one described and, therefore, can be used where a smaller propeller gear step-down is desired. In the case of gas turbine turboprop engines, more than one stage of reduction gearing is used do to the high output speeds of the engine. Several types of lower powered engines can use the spur and pinion reduction gear arrangement.

[ad-mid]

Propeller Shafts

Propeller shafts may be of three major types: tapered, splined, or flanged. Tapered shafts are identified by taper numbers. Splined and flanged shafts are identified by SAE numbers. The propeller shaft of most low power output engines is forged as part of the crankshaft. It is tapered and a milled slot is provided so that the propeller hub can be keyed to the shaft. The keyway and key index of the propeller are in relation to the No. 1 cylinder top dead center. The end of the shaft is threaded to receive the propeller retaining nut. Tapered propeller shafts are common on older and smaller engines.The propeller shaft of high-output radial engines is generally splined. It is threaded on one end for a propeller hub nut. The thrust bearing, which absorbs propeller thrust, is located around the shaft and transmits the thrust to the nose section housing. The shaft is threaded for attaching the thrust-bearing retaining nut. On the portion protruding from the housing (between the two sets of threads), splines are located to receive the splined propeller hub. The shaft is generally machined from a steel-alloy forging throughout its length. The propeller shaft may be connected by reduction gearing to the engine crankshaft, but in smaller engines the propeller shaft is simply an extension of the engine crankshaft. To turn the propeller shaft, the engine crankshaft must revolve.

Flanged propeller shafts are used on most modern reciprocating and turboprop engines. One end of the shaft is flanged with drilled holes to accept the propeller mounting bolts. The installation may be a short shaft with internal threading to accept the distributor valve to be used with a controllable propeller. The flanged propeller shaft is a very common installation on most propeller driven aircraft.

RELATED POSTS

Flanged propeller shafts are used on most modern reciprocating and turboprop engines. One end of the shaft is flanged with drilled holes to accept the propeller mounting bolts. The installation may be a short shaft with internal threading to accept the distributor valve to be used with a controllable propeller. The flanged propeller shaft is a very common installation on most propeller driven aircraft.

RELATED POSTS