|

| Figure 1. Machined rings around a piston |

Piston Ring Construction

Most piston rings are made of high-grade cast iron. [Figure 2] After the rings are made, they are ground to the cross-section desired. Then they are split so that they can be slipped over the outside of the piston and into the ring grooves that are machined in the piston wall. Since their purpose is to seal the clearance between the piston and the cylinder wall, they must fit the cylinder wall snugly enough to provide a gas tight fit. They must exert equal pressure at all points on the cylinder wall, and must make a gas tight fit against the sides of the ring grooves. |

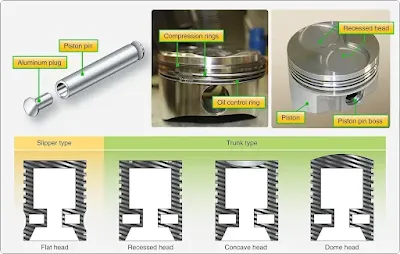

| Figure 2. Piston assembly and types of pistons |

Gray cast iron is most often used in making piston rings. In some engines, chrome-plated mild steel piston rings are used in the top compression ring groove because these rings can better withstand the high temperatures present at this point. Chrome rings must be used with steel cylinder walls. Never use chrome rings on chrome cylinders.

Compression Ring

The purpose of the compression rings is to prevent the escape of combustion gases past the piston during engine operation. They are placed in the ring grooves immediately below the piston head. The number of compression rings used on each piston is determined by the type of engine and its design, although most aircraft engines use two compression rings plus one or more oil control rings.The cross-section of the ring is either rectangular or wedge shaped with a tapered face. The tapered face presents a narrow bearing edge to the cylinder wall, which helps to reduce friction and provide better sealing.

Oil Control Rings

Oil control rings are placed in the grooves immediately below the compression rings and above the piston pin bores. There may be one or more oil control rings per piston; two rings may be installed in the same groove, or they may be installed in separate grooves. Oil control rings regulate the thickness of the oil film on the cylinder wall. If too much oil enters the combustion chamber, it burns and leaves a thick coating of carbon on the combustion chamber walls, the piston head, the spark plugs, and the valve heads. This carbon can cause the valves and piston rings to stick if it enters the ring grooves or valve guides. In addition, the carbon can cause spark plug misfiring as well as detonation, pre ignition, or excessive oil consumption. To allow the surplus oil to return to the crankcase, holes are drilled in the bottom of the oil control piston ring grooves or in the lands next to these grooves.Oil Scraper Ring

The oil scraper ring usually has a beveled face and is installed in the groove at the bottom of the piston skirt. The ring is installed with the scraping edge away from the piston head or in the reverse position, depending upon cylinder position and the engine series. In the reverse position, the scraper ring retains the surplus oil above the ring on the upward piston stroke, and this oil is returned to the crankcase by the oil control rings on the downward stroke.RELATED POSTS

- Reciprocating Engines

- Crankshafts

- Connecting Rods

- Pistons

- Cylinders

- Firing Order

- Valves

- Valve Operating Mechanism