There are numerous landing gear safety devices. The most common are those that prevent the gear from retracting or collapsing while on the ground. Gear indicators are another safety device. They are used to communicate to the pilot the position status of each individual landing gear at any time.

Landing Gear Safety Switch

A landing gear squat switch, or safety switch, is found on most aircraft. This is a switch positioned to open and close depending on the extension or compression of the main landing gear strut. [Figure 1] The squat switch is wired into any number of system operating circuits. One circuit prevents the gear from being retracted while the aircraft is on the ground.

|

| Figure 1. Typical landing gear squat switches |

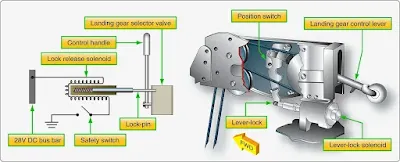

There are different ways to achieve this lock-out. A solenoid that extends a shaft to physically disable the gear position selector is one such method found on many aircraft. When the landing gear is compressed, the squat safety switch is open, and the center shaft of the solenoid protrudes a hardened lock-pin through the landing gear control handle so that it cannot be moved to the up position. At takeoff, the landing gear strut extends. The safety switch closes and allows current to flow in the safety circuit. The solenoid energizes and retracts the lock-pin from the selector handle. This permits the gear to be raised. [Figure 2]

The use of proximity sensors for gear position safety switches is common in high-performance aircraft. An electromagnetic sensor returns a different voltage to a gear logic unit depending on the proximity of a conductive target to the switch. No physical contact is made. When the gear is in the designed position, the metallic target is close to the inductor in the sensor which reduces the return voltage. This type of sensing is especially useful in the landing gear environment where switches with moving parts can become contaminated with dirt and moisture from runways and taxi ways. The technician is required to ensure that sensor targets are installed the correct distance away from the sensor. Go–no go gauges are often used to set the distance. [Figure 3]

|

| Figure 3. Proximity sensors are used instead of contact switches on many landing gear |

Ground Locks

Ground locks are commonly used on aircraft landing gear as extra insurance that the landing gear will remain down and locked while the aircraft is on the ground. They are external devices that are placed in the retraction mechanism to prevent its movement. A ground lock can be as simple as a pin placed into the pre-drilled holes of gear components that keep the gear from collapsing. Another commonly used ground lock clamps onto the exposed piston of the gear retraction cylinder that prevents it from retracting. All ground locks should have a red streamers attached to them so they are visible and removed before flight. Ground locks are typically carried in the aircraft and put into place by the flight crew during the post landing walk-around. [Figure 4]

|

| Figure 4. Gear pin ground lock devices |

Landing Gear Position Indicators

To provide a visual indication of landing gear position, indicators are installed in the flight deck or flight compartment. Gear warning devices are incorporated on all retractable gear aircraft and usually consist of a horn or some other aural device and a red warning light. The horn blows and the light comes on when one or more throttles are retarded and the landing gear is in any position other than down and locked.

Position indicators are typically:

Off = gear up and locked

Red = unsafe

Green = down and locked

There is usually an amber in transit light to indicate a gear that is in transition.

[ad-mid]Landing gear position indicators are located on the instrument panel adjacent to the gear selector handle. They are used to inform the pilot of gear position status. There are many arrangements for gear indication. Usually, there is a dedicated light for each gear. The most common display for the landing gear being down and locked is an illuminated green light. Three green lights means it is safe to land. All lights out typically indicates that the gear is up and locked, or there may be gear up indicator lights. Gear in transit lights are used on some aircraft as are barber pole displays when a gear is not up or down and locked. Blinking indicator lights also indicate gear in transit. Some manufacturer’s use a gear disagree annunciation when the landing gear is not in the same position as the selector. Many aircraft monitor gear door position in addition to the gear itself. Consult the aircraft manufacturer’s maintenance and operating manuals for a complete description of the landing gear indication system. [Figure 5 and Figure 6]

|

| Figure 5. Landing gear selector panels with position indicator lights. The Boeing 737 panel illuminates red lights above the green lights when the gear is in transit |

|

| Figure 6. Typical landing gear indicator lights and lever as found on small aircraft |

Nose Wheel Centering

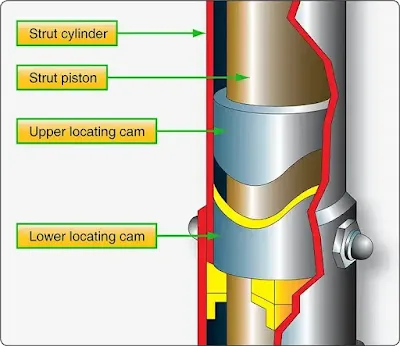

Since most aircraft have steerable nose wheel gear assemblies for taxiing, a means for aligning the nose gear before retraction is needed. Centering cams built into the shock strut structure accomplish this. An upper cam is free to mate into a lower cam recess when the gear is fully extended. This aligns the gear for retraction. When weight returns to the wheels after landing, the shock strut is compressed, and the centering cams separate allowing the lower shock strut (piston) to rotate in the upper strut cylinder. This rotation is controlled to steer the aircraft. [Figure 7] Small aircraft sometimes incorporate an external roller or guide pin on the strut. As the strut is folded into the wheel well during retraction, the roller or guide pin engages a ramp or track mounted to the wheel well structure. The ramp/track guides the roller or pin in such a manner that the nose wheel is straightened as it enters the wheel well.

|

| Figure 7. A cutaway view of a nose gear internal centering cam |