The exhaust section of the gas turbine engine consists of several components. Although the components have individual purposes, they also have one common function: they must direct the flow of hot gases rearward in such a manner as to prevent turbulence and, at the same time, impart a high final or exit velocity to the gases. In performing the various functions, each of the components affects the flow of gases in different ways. The exhaust section is located directly behind the turbine section and ends when the gases are ejected at the rear in the form of a high-velocity exhaust gases. The components of the exhaust section include the exhaust cone, tailpipe (if required), and the exhaust nozzle. The exhaust cone collects the exhaust gases discharged from the turbine section and gradually converts them into a solid flow of gases. In performing this, the velocity of the gases is decreased slightly and the pressure increased. This is due to the diverging passage between the outer duct and the inner cone; that is, the annular area between the two units increases rearward. The exhaust cone assembly consists of an outer shell or duct, an inner cone, three or four radial hollow struts or fins, and the necessary number of tie rods to aid the struts in supporting the inner cone from the outer duct.

The outer shell or duct is usually made of stainless steel and is attached to the rear flange of the turbine case. This element collects the exhaust gases and delivers them directly to the exhaust nozzle. The duct must be constructed to include such features as a predetermined number of thermocouple bosses for installing exhaust temperature thermocouples, and there must also be insertion holes for the supporting tie rods. In some cases, tie rods are not used for supporting the inner cone. If such is the case, the hollow struts provide the sole support of the inner cone, the struts being spot-welded in position to the inside surface of the duct and to the inner cone, respectively. [Figure 1]

|

| Figure 1. Exhaust collector with welded support struts |

The radial struts actually have a twofold function. They not only support the inner cone in the exhaust duct, but they also perform the important function of straightening the swirling exhaust gases that would otherwise leave the turbine at an angle of approximately 45°.

The centrally located inner cone fits rather closely against the rear face of the turbine disk, preventing turbulence of the gases as they leave the turbine wheel. The cone is supported by the radial struts. In some configurations, a small hole is located in the exit tip of the cone. This hole allows cooling air to be circulated from the aft end of the cone, where the pressure of the gases is relatively high, into the interior of the cone and consequently against the face of the turbine wheel. The flow of air is positive, since the air pressure at the turbine wheel is relatively low due to rotation of the wheel; thus air circulation is assured. The gases used for cooling the turbine wheel return to the main path of flow by passing through the clearance between the turbine disk and the inner cone. The exhaust cone assembly is the terminating component of the basic engine. The remaining component (the exhaust nozzle) is usually considered an airframe component.

The tailpipe is usually constructed so that it is semiflexible. On some tailpipes, a bellows arrangement is incorporated in its construction, allowing movement in installation, maintenance, and in thermal expansion. This eliminates stress and warping which would otherwise be present.

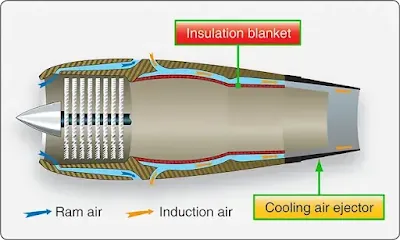

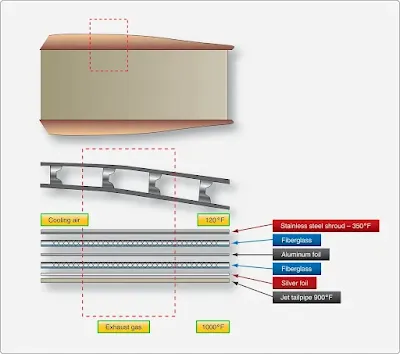

The heat radiation from the exhaust cone and tailpipe could damage the airframe components surrounding these units. For this reason, some means of insulation had to be devised. There are several suitable methods of protecting the fuselage structure; two of the most common are insulation blankets and shrouds.

The insulation blanket, illustrated in Figures 2 and 3, consists of several layers of aluminum foil, each separated by a layer of fiberglass or some other suitable material. Although these blankets protect the fuselage from heat radiation, they are used primarily to reduce heat loss from the exhaust system. The reduction of heat loss improves engine performance.

|

| Figure 2. Exhaust system insulation blanket |

|

| Figure 3. Insulation blanket with the temperatures obtained at the various locations shown |

There are two types of exhaust nozzle designs: the converging design for subsonic gas velocities and the converging-diverging design for supersonic gas velocities. These exhaust nozzle designs are discussed in greater detail in Induction and Exhaust Systems section.

The exhaust nozzle opening may be of either fixed or variable area. The fixed-area type is the simpler of the two exhaust nozzles since there are no moving parts. The outlet area of the fixed exhaust nozzle is very critical to engine performance. If the nozzle area is too large, thrust is wasted; if the area is too small, the engine could choke or stall. A variable-area exhaust nozzle is used when an augmenter or afterburner is used due to the increased mass of flow when the afterburner is activated. It must increase its open area when the afterburner is selected. When the afterburner is off, the exhaust nozzle closes to a smaller area of opening.

📂 Exhaust Section Key Takeaways

- Main Purpose: Directs hot gases rearward, eliminates swirl/turbulence, and maximizes exit velocity for thrust.

- Exhaust Cone: Acts as a divergent duct to stabilize the gas flow and increase static pressure before the nozzle.

- Straightening Struts: Convert the 45° swirling air from the turbine into a straight axial flow.

- Thermal Protection: Uses insulation blankets (fiberglass/foil) and shrouds to protect the airframe from radiant heat.

- Nozzle Types: Convergent nozzles are used for subsonic flight; Converging-Diverging (C-D) nozzles are required for supersonic velocities.