Eddy Current Inspection

Electromagnetic analysis is a term describing the broad spectrum of electronic test methods involving the intersection of magnetic fields and circulatory currents. The most widely used technique is the eddy current. Eddy currents are composed of free electrons under the influence of an induced electromagnetic field that are made to “drift” through metal. Eddy current is used to detect surface cracks, pits, subsurface cracks, corrosion on inner surfaces, and to determine alloy and heat-treat condition.

Eddy current is used in aircraft maintenance to inspect jet engine turbine shafts and vanes, wing skins, wheels, bolt holes, and spark plug bores for cracks, heat, or frame damage. Eddy current may also be used in repair of aluminum aircraft damaged by fire or excessive heat. Different meter readings are seen when the same metal is in different hardness states. Readings in the affected area are compared with identical materials in known unaffected areas for comparison. A difference in readings indicates a difference in the hardness state of the affected area. In aircraft manufacturing plants, eddy current is used to inspect castings, stampings, machine parts, forgings, and extrusions. Figure 1 shows a technician performing an eddy current inspection on a fan blade.

Basic Principles

When an alternating current (AC) is passed through a coil, it develops a magnetic field around the coil, which in turn induces a voltage of opposite polarity in the coil and opposes the flow of original current. If this coil is placed in such a way that the magnetic field passes through an electrically conducting specimen, eddy currents are induced into the specimen. The eddy currents create their own field that varies the original field’s opposition to the flow of original current. The specimen’s susceptibility to eddy currents determines the current flow through the coil.

The magnitude and phase of this counter field is dependent primarily upon the resistance and permeability of the specimen under consideration and enables us to make a qualitative determination of various physical properties of the test material. The interaction of the eddy current field with the original field results is a power change that can be measured by utilizing electronic circuitry similar to a Wheatstone bridge.

[ad-mid]

Principles of Operations

Eddy currents are induced in a test article when an AC is applied to a test coil (probe). The AC in the coil induces an alternating magnetic field in the article, causing eddy currents to flow in the article. [Figure 2]

Flaws in or thickness changes of the test-piece influence the flow of eddy currents and change the impedance of the coil accordingly. [Figure 3] Instruments display the impedance changes either by impedance plane plots or by needle deflection. [Figure 4]

The specimen is either placed in or passed through the field of an electromagnetic induction coil, and its effect on the impedance of the coil or on the voltage output of one or more test coils is observed. The process that involves electric fields made to explore a test piece for various conditions involves the transmission of energy through the specimen much like the transmission of x-rays, heat, or ultrasound.

Eddy current inspection can frequently be performed without removing the surface coatings, such as primer, paint, and anodized films. It can be effective in detecting surface and subsurface corrosion, pots, and heat treat condition.

[ad-long]

Eddy Current Instruments

A wide variety of eddy current test instruments are available. The eddy current test instrument performs three basic functions: generating, receiving, and displaying. The generating portion of the unit provides an alternating current to the test coil. The receiving section processes the signal from the test coil to the required form and amplitude for display. Instrument outputs or displays consist of a variety of visual, audible, storage, or transfer techniques utilizing meters, video displays, chart recorders, alarms, magnetic tape, computers, and electrical or electronic relays.

A reference standard is required for the calibration of eddy current test equipment. A reference standard is made from the same material as the item is to be tested. A reference standard contains known flaws or cracks and could include items, such as a flat surface notch, a fastener head, a fastener hole, or a countersink hole. Figures 5, 6, and 7 show typical surface cracks, subsurface cracks, and structural corrosion that can be detected with eddy current techniques.

Ultrasonic Inspection

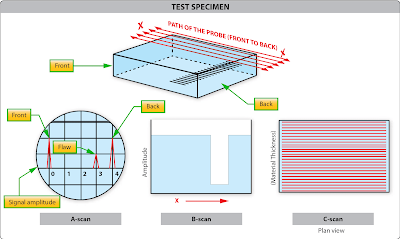

Ultrasonic inspection is an NDI technique that uses sound energy moving through the test specimen to detect flaws. The sound energy passing through the specimen is displayed on a cathode ray tube (CRT), a liquid crystal display (LCD) computer data program, or video/camera medium. Indications of the front and back surface and internal/external conditions appear as vertical signals on the CRT screen or nodes of data in the computer test program. [Figure 8] There are three types of display patterns: “A” scan, “B” scan, and “C” scan. Each scan provides a different picture or view of the specimen being tested. [Figure 9]

Ultrasonic detection equipment makes it possible to locate defects in all types of materials. Minute cracks, checks, and voids too small to be seen by x-ray can be located by ultrasonic inspection. An ultrasonic test instrument requires access to only one surface of the material to be inspected and can be used with either straight line or angle beam testing techniques.

Two basic methods are used for ultrasonic inspection. The first of these methods is immersion testing. In this method of inspection, the part under examination and the search unit are completely immersed in a liquid couplant, such as water or other suitable fluids.

The second method is called contact testing. It is readily adapted to field use and is the method discussed. In this method, the part under examination and the search unit are coupled with a viscous material, liquid, or a paste that wets both the face of the search unit and the material under examination.

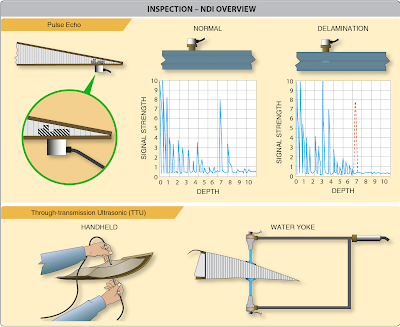

There are three basic ultrasonic inspection methods: pulse echo, through transmission, and resonance. Through transmission and pulse echo are shown in Figure 10.

Pulse Echo

Flaws are detected by measuring the amplitude of signals reflected and the time required for these signals to travel between specific surfaces and the discontinuity. [Figure 11]

The time base, triggered simultaneously with each transmission pulse, causes a spot to sweep across the screen of the CRT or LCD. The spot sweeps from left to right across the face of the scope 50 to 5,000 times per second or higher if required for high-speed automated scanning. Due to the speed of the cycle of transmitting and receiving, the picture on the oscilloscope appears to be stationary.

A few microseconds after the sweep is initiated, the rate generator electrically excites the pulser, and the pulser in turn emits an electrical pulse. The transducer converts this pulse into a short train of ultrasonic sound waves. If the interfaces of the transducer and the specimen are properly oriented, the ultrasound is reflected back to the transducer when it reaches the internal flaw and the opposite surface of the specimen. The time interval between the transmission of the initial impulse and the reception of the signals from within the specimen are measured by the timing circuits. The reflected pulse received by the transducer is amplified, transmitted to, and displayed on the instrument screen. The pulse is displayed in the same relationship to the front and back pulses as the flaw is in relation to the front and back surfaces of the specimen. [Figure 12]

Pulse-echo instruments may also be used to detect flaws not directly underneath the probe by use of the angle beam testing method. Angle beam testing differs from straight beam testing only in the manner that the ultrasonic waves pass through the material being tested. As shown in Figure 13, the beam is projected into the material at an acute angle to the surface by means of a crystal cut at an angle and mounted in plastic. The beam, or a portion thereof, reflects successively from the surfaces of the material or any other discontinuity, including the edge of the piece. In straight beam testing, the horizontal distance on the screen between the initial pulse and the first back reflection represents the thickness of the piece; while in angle beam testing, this distance represents the width of the material between the searching unit and the opposite edge of the piece.

Through Transmission

Through transmission inspection uses two transducers, one to generate the pulse and another placed on the opposite surface to receive it. A disruption in the sound path indicates a flaw and is displayed on the instrument screen. Through transmission is less sensitive to small defects than the pulse-echo method.

[ad-longer]

Resonance

This system differs from the pulse method in that the frequency of transmission may be continuously varied. The resonance method is used principally for thickness measurements when the two sides of the material being tested are smooth and parallel and the backside is inaccessible. The point where the frequency matches the resonance point of the material being tested is the thickness determining factor. It is necessary that the frequency of the ultrasonic waves corresponding to a particular dial setting be accurately known. Checks are made with standard test blocks to guard against possible drift of frequency.

If the frequency of an ultrasonic wave is such that its wavelength is twice the thickness of a specimen (fundamental frequency), then the reflected wave arrives back at the transducer in the same phase as the original transmission so that strengthening of the signal occurs. This results from constructive interference or a resonance and is shown as a high amplitude value on the indicating screen. If the frequency is increased such that three times the wavelength equals four times the thickness, the reflected signal returns completely out of phase with the transmitted signal and cancellation occurs. Further increase of the frequency causes the wavelength to be equal to the thickness again and gives a reflected signal in phase with the transmitted signal and a resonance once more. By starting at the fundamental frequency and gradually increasing the frequency, the successive cancellations and resonances can be noted and the readings used to check the fundamental frequency reading. [Figure 14]

In some instruments, the oscillator circuit contains a motor-driven capacitor that changes the frequency of the oscillator. [Figure 15] In other instruments, the frequency is changed by electronic means. The change in frequency is synchronized with the horizontal sweep of a CRT. The horizontal axis represents a frequency range. If the frequency range contains resonances, the circuitry is arranged to present these vertically. Calibrated transparent scales are then placed in front of the tube and the thickness can be read directly. The instruments normally operate between 0.25 millicycle (mc) and 10 mc in four or five bands.

The resonance thickness instrument can be used to test the thickness of such metals as steel, cast iron, brass, nickel, copper, silver, lead, aluminum, and magnesium. In addition, areas of corrosion or wear on tanks, tubing, airplane wing skins, and other structures or products can be located and evaluated. Direct reading dial-operated units are available that measure thickness between 0.025 inch and 3 inches with an accuracy of better than ±1 percent. Ultrasonic inspection requires a skilled operator who is familiar with the equipment being used, as well as the inspection method to be used for the many different parts being tested. [Figure 16]

Ultrasonic Instruments

A portable, battery-powered ultrasonic instrument is used for field inspection of airplane structure. The instrument generates an ultrasonic pulse, detects and amplifies the returning echo, and displays the detected signal on a CRT or similar display. Piezoelectric transducers produce longitudinal or shear waves, the most commonly used wave forms for aircraft structural inspection.

Reference Standards

Reference standards are used to calibrate the ultrasonic instrument. Reference standards serve two purposes: to provide an ultrasonic response pattern that is related to the part being inspected and to establish the required inspection sensitivity. To obtain a representative response pattern, the reference standard configuration is the same as that of the test structure or is a configuration that provides an ultrasonic response pattern representative of the test structure. The reference standard contains a simulated defect (notch) that is positioned to provide a calibration signal representative of the expected defect. The notch size is chosen to establish inspection sensitivity (response to the expected defect size). The inspection procedure gives a detailed description of the required reference standard.

Couplants

Inspection with ultrasonics is limited to the part in contact with the transducer. A layer of couplant is required to couple the transducer to the test piece, because ultrasonic energy does not travel through air. Some typical couplants used are water, glycerin, motor oils, and grease.