Light-Sport Aircraft Engines

Light-sport/ultralight aircraft engines can be classified by several methods, such as by operating cycles, cylinder arrangement, and air or water cooled. An inline engine generally has two cylinders, is two-cycle, and is available in several horsepower ranges. These engines may be either liquid cooled, air cooled, or a combination of both. They have only one crankshaft that drives the reduction gear box or propeller directly. Most of the other cylinder configurations used are horizontally opposed, ranging from two to six cylinders from several manufacturers. These engines are either gear reduction or direct drive.

Two-Cycle, Two Cylinder Rotax Engine Single Capacitor Discharge Ignition (SCDI) Dual Capacitor Discharge Ignition (DCDI)

Rotax 447 UL (SCDI) and Rotax 503 UL (DCDI)

The Rotax inline cylinder arrangement has a small frontal area and provides improved streamlining. [Figure 1] |

| Figure 1. Rotax inline cylinder arrangement |

The two cylinder, inline two-stroke engine, which is piston ported with air cooled cylinder heads and cylinders, is available in a fan or free air cooled version. Being a two-stroke cycle engine, the oil and fuel must be mixed in the fuel tank on some models. Other models use a lubrication system, such as the 503 oil injection lubrication system. This system does not mix the fuel and oil as the oil is stored in a separate tank.

As the engine needs lubrication, the oil is injected directly from this tank. The typical ignition system is a breakerless ignition system with a dual ignition system used on the 503, and a single ignition system used on the 447 engine series. Both systems are of a magneto capacitor discharge design.

The engine is equipped with a carburetion system with one or two piston-type carburetors. One pneumatic driven fuel pump delivers the fuel to the carburetors. The propeller is driven via a flange connected gearbox with an incorporated shock absorber. The exhaust system collects the exhaust gases and directs them overboard. These engines come with an integrated alternating current (AC) generator (12V 170W) with external rectifier-regulator as an optional extra.

Rotax 582 UL DCDI

The Rotax 582 is a two-stroke engine, two cylinder inline with rotary valve inlet, has liquid cooled cylinder heads and cylinders that use an integrated water pump. [Figure 2] The lubrication system can be a fuel/oil mixture or oil injection lubrication. The ignition system is a dual ignition using a breakerless magneto capacitor discharge design. Dual piston type carburetors and a pneumatic fuel pump deliver the fuel to the cylinders. The propeller is driven via the prop flange connected gearbox with an incorporated torsional vibration shock absorber. This engine also uses a standard version exhaust system with an electric starter or manual rewind starter.Description of Systems for Two-Stroke Engines

Cooling System of Rotax 447 UL SCDI and Rotax 503 UL DCDI

Two versions of air cooling are available for these engines. The first method is free air cooling, which is a process of engine cooling by an air-stream generated by aircraft speed and propeller. The second is fan cooling, which is cooling by an air-stream generated by a fan permanently driven from the crankshaft via a V-belt.Cooling System of the Rotax 582 UL DCDI

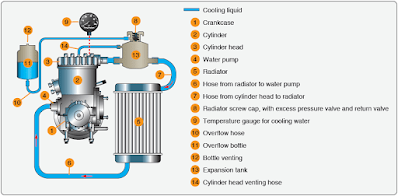

Engine cooling for the Rotax 582 is accomplished by liquid cooled cylinders and cylinder heads. [Figure 3] The cooling system is in a two circuit arrangement. The cooling liquid is supplied by an integrated pump in the engine through the cylinders and the cylinder head to the radiator. The cooling system has to be installed, so that vapor coming from the cylinders and the cylinder head can escape to the top via a hose, either into the water tank of the radiator or to an expansion chamber. The expansion tank is closed by a pressure cap (with excess pressure valve and return valve). As the temperature of the coolant rises, the excess pressure valve opens, and the coolant flows via a hose at atmospheric pressure to the transparent overflow bottle. When cooling down, the coolant is sucked back into the cooling circuit.Lubrication Systems

Oil Injection Lubrication of Rotax 503 UL DCDE, 582 UL DCDI, and 582 UL DCDI

Generally, the smaller two cycle engines are designed to run on a mixture of gasoline and 2 percent oil that is premixed in the fuel tank. The engines are planned to run on an oil-gasoline mixture of 1:50. Other engines use oil injection systems that use an oil pump driven by the crankshaft via the pump gear that feeds the engine with the correct amount of fresh oil. The oil pump is a piston type pump with a metering system. Diffuser jets in the intake inject pump supplied two-stroke oil with the exact proportioned quantity needed. The oil quantity is defined by the engine rotations per minute and the oil pump lever position. This lever is actuated via a cable connected to the throttle cable. The oil comes to the pump from an oil tank by gravity.NOTE: In engines that use oil injection, the carburetors are fed with pure gasoline (no oil/gasoline mixture). The oil quantity in the oil tank must be checked before putting the engine into service as the oil is consumed during operation and needs to be replenished.

Electric System

The 503 UL DCDI, 582 UL DCDI engine types are equipped with a breakerless, single capacitor discharge ignition unit with an integrated generator. [Figure 4] The 447 UL SCDI engine is equipped with a breakerless, single capacitor discharge ignition unit with integrated generator. The ignition unit is completely free of maintenance and needs no external power supply. Two charging coils fitted on the generator stator, independent from each other, each feed one ignition circuit. The energy supplied is stored in the ignition capacitor. At the moment of ignition, the external triggers supply an impulse to the control circuits and the ignition capacitors are discharged via the primary winding of the ignition coil. The secondary winding supplies the high voltage for the ignition spark.Fuel System

Due to higher lead content in aviation gas (AVGAS), operation can cause wear and deposits in the combustion chamber to increase. Therefore, AVGAS should only be used if problems are encountered with vapor lock or if the other fuel types are not available. Caution must be exercised to use only fuel suitable for the relevant climatic conditions, such as using winter fuel for summer operation.Fuel/Oil Mixing Procedure

The following describes the process for fuel/oil mixing. Use a clean approved container of known volume. To help predilute the oil, pour a small amount of fuel into the container. Fill known amount of oil (two-stroke oil ASTM/Coordinating European Council (CEC) standards, API-TC classification (e.g., Castrol TTS) mixing ratio 1:50 (2 percent)), into container. Oil must be approved for air-cooled engines at 50:1 mixing ratio. Agitate slightly to dilute oil with gasoline. Add gasoline to obtain desired mixture ratio; use fine mesh screen. Replace the container cap and shake the container thoroughly. Then, using a funnel with a fine mesh screen to prevent the entry of water and foreign particles, transfer mixture from container into the fuel tank.WARNING: To avoid electrostatic charging at refueling, use only metal containers and ground the aircraft in accordance with the grounding specifications.

Note: All information in this text is for educational illustrational purposes and is not to be used for actual aircraft maintenance. This information is not revised at the same rate as the maintenance manual; always refer to the current maintenance information when performing maintenance on any engine.

RELATED POSTS

RELATED POSTS

- Engine General Requirements

- Personnel Authorized to Perform Inspection and Maintenance on Light-sport Engines

- Opposed Light-Sport, Experimental, and Certified Aircraft Engines

- Direct Drive VW Engines

- Maintenance Schedule Procedures and Maintenance Checklist

- Lubrication System Maintenance

- Preflight Checks, Troubleshooting, Abnormal Operation and Preservation

- Light-Sport Jabiru Engines Maintenance Practices and Engine Inspection Charts