The solid shank rivet is the most common type of rivet used in aircraft construction. Used to join aircraft structures, solid shank rivets are one of the oldest and most reliable types of fastener. Widely used in the aircraft manufacturing industry, solid shank rivets are relatively low-cost, permanently installed fasteners. They are faster to install than bolts and nuts since they adapt well to automatic, high-speed installation tools. Rivets should not be used in thick materials or in tensile applications, as their tensile strengths are quite low relative to their shear strength. The longer the total grip length (the total thickness of sheets being joined), the more difficult it becomes to lock the rivet.

Riveted joints are neither airtight nor watertight unless special seals or coatings are used. Since rivets are permanently installed, they must be removed by drilling them out, a laborious task.

Before installation, the rivet consists of a smooth cylindrical shaft with a factory head on one end. The opposite end is called the bucktail. To secure two or more pieces of sheet metal together, the rivet is placed into a hole cut just a bit larger in diameter than the rivet itself. Once placed in this predrilled hole, the bucktail is upset or deformed by any of several methods from hand-held hammers to pneumatically driven squeezing tools. This action causes the rivet to expand about 11⁄2 times the original shaft diameter, forming a second head that firmly holds the material in place.

Rivet Head Shape

Solid rivets are available in several head shapes, but the universal and the 100° countersunk head are the most commonly used in aircraft structures. Universal head rivets were developed specifically for the aircraft industry and designed as a replacement for both the round and brazier head rivets. These rivets replaced all protruding head rivets and are used primarily where the protruding head has no aerodynamic significant. They have a flat area on the head, a head diameter twice the shank diameter, and a head height approximately 42.5 percent of the shank diameter. [Figure 1] |

| Figure 1. Solid shank rivet styles |

Typically, rivets are fabricated from aluminum alloys, such as 2017-T4, 2024-T4, 2117-T4, 7050, and 5056. Titanium, nickel-based alloys, such as Monel® (corrosion-resistant steel), mild steel or iron, and copper rivets are also used for rivets in certain cases.

[ad-mid]

Rivets are available in a wide variety of alloys, head shapes, and sizes and have a wide variety of uses in aircraft structure. Rivets that are satisfactory for one part of the aircraft are often unsatisfactory for another part. Therefore, it is important that an aircraft technician know the strength and driving properties of the various types of rivets and how to identify them, as well as how to drive or install them.

Solid rivets are classified by their head shape, by the material from which they are manufactured, and by their size. Identification codes used are derived from a combination of the Military Standard (MS) and National Aerospace Standard (NAS) systems, as well as an older classification system known as AN for Army/Navy. For example, the prefix MS identifies hardware that conforms to written military standards. A letter or letters following the head-shaped code identify the material or alloy from which the rivet was made. The alloy code is followed by two numbers separated by a dash. The first number is the numerator of a fraction, which specifies the shank diameter in thirty-seconds of an inch. The second number is the numerator of a fraction in sixteenths of an inch and identifies the length of the rivet. Rivet head shapes and their identifying code numbers are shown in Figure 2.

|

| Figure 2. Rivet head shapes and their identifying code numbers |

The head type, size, and strength required in a rivet are governed by such factors as the kind of forces present at the point riveted, the kind and thickness of the material to be riveted, and the location of the part on the aircraft. The type of head needed for a particular job is determined by where it is to be installed. Countersunk head rivets should be used where a smooth aerodynamic surface is required. Universal head rivets may be used in most other areas.

The size (or diameter) of the selected rivet shank should correspond in general to the thickness of the material being riveted. If an excessively large rivet is used in a thin material, the force necessary to drive the rivet properly causes an undesirable bulging around the rivet head. On the other hand, if an excessively small rivet diameter is selected for thick material, the shear strength of the rivet is not great enough to carry the load of the joint. As a general rule, the rivet diameter should be at least two and a half to three times the thickness of the thicker sheet. Rivets most commonly chosen in the assembly and repair of aircraft range from 3⁄32-inch to 3⁄8-inch in diameter. Ordinarily, rivets smaller than 3⁄32-inch in diameter are never used on any structural parts that carry stresses.

The proper sized rivets to use for any repair can also be determined by referring to the rivets (used by the manufacturer) in the next parallel row inboard on the wing or forward on the fuselage. Another method of determining the size of rivets to be used is to multiply the skin’s thickness by 3 and use the next larger size rivet corresponding to that figure. For example, if the skin is 0.040 inch thick, multiply 0.040 inch by 3 to get 0.120 inch and use the next larger size of rivet, 1⁄8-inch (0.125 inch).

When rivets are to pass completely through tubular members, select a rivet diameter equivalent to at least 1⁄8 the outside diameter of the tube. If one tube sleeves or fits over another, take the outside diameter of the outside tube and use oneeighth of that distance as the minimum rivet diameter. A good practice is to calculate the minimum rivet diameter and then use the next larger size rivet.

Whenever possible, select rivets of the same alloy number as the material being riveted. For example, use 1100 and 3003 rivets on parts fabricated from 1100 and 3003 alloys, and 2117-1 and 2017-T rivets on parts fabricated from 2017 and 2024 alloys.

The size of the formed head is the visual standard of a proper rivet installation. The minimum and maximum sizes, as well as the ideal size, are shown in Figure 3.

|

| Figure 3. Rivet formed head dimensions |

Installation of Rivets

Repair Layout

Repair layout involves determining the number of rivets required, the proper size and style of rivets to be used, their material, temper condition and strength, the size of the holes, the distances between the holes, and the distance between the holes and the edges of the patch. Distances are measured in terms of rivet diameter.Rivet Length

To determine the total length of a rivet to be installed, the combined thickness of the materials to be joined must first be known. This measurement is known as the grip length. The total length of the rivet equals the grip length plus the amount of rivet shank needed to form a proper shop head. The latter equals one and a half times the diameter of the rivet shank. Where A is total rivet length, B is grip length, and C is the length of the material needed to form a shop head, this formula can be represented as A = B + C.Rivet Strength

For structural applications, the strength of the replacement rivets is of primary importance. [Figure 4] Rivets made of material that is lower in strength should not be used as replacements unless the shortfall is made up by using a larger rivet. For example, a rivet of 2024-T4 aluminum alloy should not be replaced with one of 2117-T4 or 2017-T4 aluminum alloy unless the next larger size is used. |

| Figure 4. Rivet allow strength |

A general rule to follow on a flush-riveted aircraft is to apply flush rivets on the upper surface of the wing and stabilizers, on the lower leading edge back to the spar, and on the fuselage back to the high point of the wing. Use universal head rivets in all other surface areas. Whenever possible, select rivets of the same alloy number as the material being riveted.

Stresses Applied to Rivets

Shear is one of the two stresses applied to rivets. The shear strength is the amount of force required to cut a rivet that holds two or more sheets of material together. If the rivet holds two parts, it is under single shear; if it holds three sheets or parts, it is under double shear. To determine the shear strength, the diameter of the rivet to be used must be found by multiplying the thickness of the skin material by 3. For example, a material thickness of 0.040 inch multiplied by 3 equals 0.120 inch. In this case, the rivet diameter selected would be 1⁄8 (0.125) inch.Tension is the other stress applied to rivets. The resistance to tension is called bearing strength and is the amount of tension required to pull a rivet through the edge of two sheets riveted together or to elongate the hole.

[ad-long]

Rivet Spacing

Rivet spacing is measured between the centerlines of rivets in the same row. The minimum spacing between protruding head rivets shall not be less than 31⁄2 times the rivet diameter. The minimum spacing between flush head rivets shall not be less than 4 times the diameter of the rivet. These dimensions may be used as the minimum spacing except when specified differently in a specific repair procedure or when replacing existing rivets.On most repairs, the general practice is to use the same rivet spacing and edge distance (distance from the center of the hole to the edge of the material) that the manufacturer used in the area surrounding the damage. The SRM for the particular aircraft may also be consulted. Aside from this fundamental rule, there is no specific set of rules that governs spacing of rivets in all cases. However, there are certain minimum requirements that must be observed.

- When possible, rivet edge distance, rivet spacing, and distance between rows should be the same as that of the original installation.

- When new sections are to be added, the edge distance measured from the center of the rivet should never be less than 2 times the diameter of the shank; the distance between rivets or pitch should be at least 3 times the diameter; and the distance between rivet rows should never be less than 21⁄2 times the diameter.

Figure 5 illustrates acceptable ways of laying out a rivet pattern for a repair.

|

| Figure 5. Acceptable rivet patterns |

Edge Distance

Edge distance, also called edge margin by some manufacturers, is the distance from the center of the first rivet to the edge of the sheet. It should not be less than 2 or more than 4 rivet diameters and the recommended edge distance is about 21⁄2 rivet diameters. The minimum edge distance for universal rivets is 2 times the diameter of the rivet; the minimum edge distance for countersunk rivets is 21⁄2 times the diameter of the rivet. If rivets are placed too close to the edge of the sheet, the sheet may crack or pull away from the rivets. If they are spaced too far from the edge, the sheet is likely to turn up at the edges. [Figure 6] |

| Figure 6. Minimum edge distance |

Two methods for obtaining edge distance:

- The rivet diameter of a protruding head rivet is 3⁄32-inch. Multiply 2 times 3⁄32-inch to obtain the minimum edge distance, 3⁄16-inch, add 1⁄16-inch to yield the preferred edge distance of 1⁄4-inch.

- The rivet diameter of a protruding head rivet is 3⁄32-inch. Select the next size of rivet, which is 1⁄8-inch. Calculate the edge distance by multiplying 2 times 1⁄8-inch to get 1⁄4-inch.

Rivet Pitch

Rivet pitch is the distance between the centers of neighboring rivets in the same row. The smallest allowable rivet pitch is 3 rivet diameters. The average rivet pitch usually ranges from 4 to 6 rivet diameters, although in some instances rivet pitch could be as large as 10 rivet diameters. Rivet spacing on parts that are subjected to bending moments is often closer to the minimum spacing to prevent buckling of the skin between the rivets. The minimum pitch also depends on the number of rows of rivets. One-and three-row layouts have a minimum pitch of 3 rivet diameters, a two-row layout has a minimum pitch of 4 rivet diameters. The pitch for countersunk rivets is larger than for universal head rivets. If the rivet spacing is made at least 1⁄16-inch larger than the minimum, the rivet hole can be oversized without violating the minimum rivet spacing requirement. [Figure 7]Transverse Pitch

Transverse pitch is the perpendicular distance between rivet rows. It is usually 75 percent of the rivet pitch. The smallest allowable transverse pitch is 21⁄2 rivet diameters. The smallest allowable transverse pitch is 21⁄2 rivet diameters. Rivet pitch and transverse pitch often have the same dimension and are simply called rivet spacing.Rivet Layout Example

The general rules for rivet spacing, as it is applied to a straight-row layout, are quite simple. In a one-row layout, find the edge distance at each end of the row and then lay off the rivet pitch (distance between rivets), as shown in Figure 8. In a two-row layout, lay off the first row, place the second row a distance equal to the transverse pitch from the first row, and then lay off rivet spots in the second row so that they fall midway between those in the first row. In the three-row layout, first lay off the first and third rows, then use a straightedge to determine the second row rivet spots. |

| Figure 8. Rivet layout |

Rivet Installation Tools

The various tools needed in the normal course of driving and upsetting rivets include drills, reamers, rivet cutters or nippers, bucking bars, riveting hammers, draw sets, dimpling dies or other types of countersinking equipment, rivet guns, and squeeze riveters. C-clamps, vises, and other fasteners used to hold sheets together when riveting were discussed in the Sheet Metal Holding Devices post. Other tools and equipment needed in the installation of rivets are discussed in Rivet Installation Tools Post.[ad-longer]

Riveting Procedure

The riveting procedure consists of transferring and preparing the hole, drilling, and driving the rivets.Hole Transfer

Accomplish transfer of holes from a drilled part to another part by placing the second part over first and using established holes as a guide. Using an alternate method, scribe hole location through from drilled part onto part to be drilled, spot with a center punch, and drill.Hole Preparation

It is very important that the rivet hole be of the correct size and shape and free from burrs. If the hole is too small, the protective coating is scratched from the rivet when the rivet is driven through the hole. If the hole is too large, the rivet does not fill the hole completely. When it is bucked, the joint does not develop its full strength, and structural failure may occur at that spot.If countersinking is required, consider the thickness of the metal and adopt the countersinking method recommended for that thickness. If dimpling is required, keep hammer blows or dimpling pressures to a minimum so that no undue work hardening occurs in the surrounding area.

Drilling

Rivet holes in repair may be drilled with either a light power drill or a hand drill. The standard shank twist drill is most commonly used. Drill bit sizes for rivet holes should be the smallest size that permits easy insertion of the rivet, approximately 0.003-inch greater than the largest tolerance of the shank diameter. The recommended clearance drill bits for the common rivet diameters are shown in Figure 9. Hole sizes for other fasteners are normally found on work documents, prints, or in manuals. |

| Figure 9. Drill sizes for standard rivets |

To drill, proceed as follows:

- Ensure the drill bit is the correct size and shape.

- Place the drill in the center-punched mark. When using a power drill, rotate the bit a few turns before starting the motor.

- While drilling, always hold the drill at a 90º angle to the work or the curvature of the material.

- Avoid excessive pressure, let the drill bit do the cutting, and never push the drill bit through stock.

- Remove all burrs with a metal countersink or a file.

- Clean away all drill chips.

When holes are drilled through sheet metal, small burrs are formed around the edge of the hole. This is especially true when using a hand drill because the drill speed is slow and there is a tendency to apply more pressure per drill revolution. Remove all burrs with a burr remover or larger size drill bit before riveting.

Driving the Rivet

Although riveting equipment can be either stationary or portable, portable riveting equipment is the most common type of riveting equipment used to drive solid shank rivets in airframe repair work.Before driving any rivets into the sheet metal parts, be sure all holes line up perfectly, all shavings and burrs have been removed, and the parts to be riveted are securely fastened with temporary fasteners. Depending on the job, the riveting process may require one or two people. In solo riveting, the riveter holds a bucking bar with one hand and operates a riveting gun with the other.

If the job requires two aircraft technicians, a shooter, or gunner, and a bucker work together as a team to install rivets. An important component of team riveting is an efficient signaling system that communicates the status of the riveting process. This signaling system usually consists of tapping the bucking bar against the work and is often called the tap code. One tap may mean not fully seated, hit it again, while two taps may mean good rivet, and three taps may mean bad rivet, remove and drive another. Radio sets are also available for communication between the technicians.

Once the rivet is installed, there should be no evidence of rotation of rivets or looseness of riveted parts. After the trimming operation, examine for tightness. Apply a force of 10 pounds to the trimmed stem. A tight stem is one indication of an acceptable rivet installation. Any degree of looseness indicates an oversize hole and requires replacement of the rivet with an oversize shank diameter rivet. A rivet installation is assumed satisfactory when the rivet head is seated snugly against the item to be retained (0.005-inch feeler gauge should not go under rivet head for more than one-half the circumference) and the stem is proved tight.

[ad-longest]

Countersunk Rivets

An improperly made countersink reduces the strength of a flush-riveted joint and may even cause failure of the sheet or the rivet head. The two methods of countersinking commonly used for flush riveting in aircraft construction and repair are:- Machine or drill countersinking.

- Dimpling or press countersinking.

The proper method for any particular application depends on the thickness of the parts to be riveted, the height and angle of the countersunk head, the tools available, and accessibility.

Countersinking

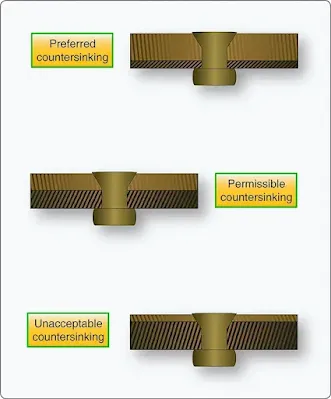

When using countersunk rivets, it is necessary to make a conical recess in the skin for the head. The type of countersink required depends upon the relation of the thickness of the sheets to the depth of the rivet head. Use the proper degree and diameter countersink and cut only deep enough for the rivet head and metal to form a flush surface.Countersinking is an important factor in the design of fastener patterns, as the removal of material in the countersinking process necessitates an increase in the number of fasteners to assure the required load-transfer strength. If countersinking is done on metal below a certain thickness, a knife edge with less than the minimum bearing surface or actual enlarging of the hole may result. The edge distance required when using countersunk fasteners is greater than when universal head fasteners are used.

The general rule for countersinking and flush fastener installation procedures has been reevaluated in recent years because countersunk holes have been responsible for fatigue cracks in aircraft pressurized skin. In the past, the general rule for countersinking held that the fastener head must be contained within the outer sheet. A combination of countersinks too deep (creating a knife edge), number of pressurization cycles, fatigue, deterioration of bonding materials, and working fasteners caused a high stress concentration that resulted in skin cracks and fastener failures. In primary structure and pressurized skin repairs, some manufacturers are currently recommending the countersink depth be no more than 2⁄3 the outer sheet thickness or down to 0.020-inch minimum fastener shank depth, whichever is greater. Dimple the skin if it is too thin for machine countersinking. [Figure 10]

|

| Figure 10. Countersinking dimensions |

Countersinking Tools

While there are many types of countersink tools, the most commonly used has an included angle of 100°. Sometimes types of 82° or 120° are used to form countersunk wells. A six-fluted countersink works best in aluminum. There are also four- and three-fluted countersinks, but those are harder to control from a chatter standpoint. A single-flute type, such as those manufactured by the Weldon Tool Company®, works best for corrosion-resistant steel. [Figure 11] |

| Figure 11. Single-flute countersink |

Freehand countersinking is needed where a microstop countersink cannot fit. This method should be practiced on scrap material to develop the required skill. Holding the drill motor steady and perpendicular is as critical during this operation as when drilling.

Chattering is the most common problem encountered when countersinking. Some precautions that may eliminate or minimize chatter include:

- Use sharp tooling.

- Use a slow speed and steady firm pressure.

- Use a piloted countersink with a pilot approximately 0.002-inch smaller than the hole.

- Use back-up material to hold the pilot steady when countersinking thin sheet material.

- Use a cutter with a different number of flutes.

- Pilot drill an undersized hole, countersink, and then enlarge the hole to final size.

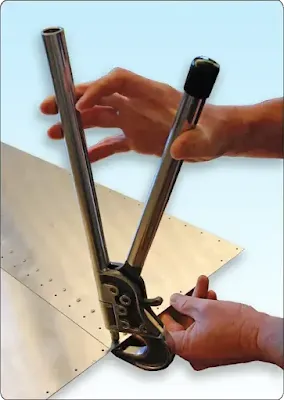

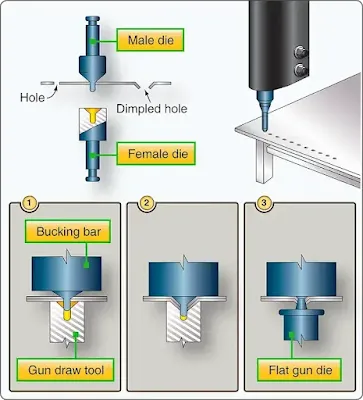

Dimpling

Dimpling is the process of making an indentation or a dimple around a rivet hole to make the top of the head of a countersunk rivet flush with the surface of the metal. Dimpling is done with a male and female die, or forms, often called punch and die set. The male die has a guide the size of the rivet hole and is beveled to correspond to the degree of countersink of the rivet head. The female die has a hole into which the male guide fits and is beveled to a corresponding degree of countersink.When dimpling, rest the female die on a solid surface. Then, place the material to be dimpled on the female die. Insert the male die in the hole to be dimpled and, with a hammer, strike the male die until the dimple is formed. Two or three solid hammer blows should be sufficient. A separate set of dies is necessary for each size of rivet and shape of rivet head. An alternate method is to use a countersunk head rivet instead of the regular male punch die, and a draw set instead of the female die, and hammer the rivet until the dimple is formed.

Dimpling dies for light work can be used in portable pneumatic or hand squeezers. [Figure 12] If the dies are used with a squeezer, they must be adjusted accurately to the thickness of the sheet being dimpled. A table riveter is also used for dimpling thin skin material and installing rivets. [Figure 13]

|

| Figure 12. Hand squeezers |

Coin Dimpling

The coin dimpling, or coin pressing, method uses a countersink rivet as the male dimpling die. Place the female die in the usual position and back it with a bucking bar. Place the rivet of the required type into the hole and strike the rivet with a pneumatic riveting hammer. Coin dimpling should be used only when the regular male die is broken or not available. Coin pressing has the distinct disadvantage of the rivet hole needing to be drilled to correct rivet size before the dimpling operation is accomplished. Since the metal stretches during the dimpling operation, the hole becomes enlarged and the rivet must be swelled slightly before driving to produce a close fit. Because the rivet head causes slight distortions in the recess, and these are characteristic only to that particular rivet head, it is wise to drive the same rivet that was used as the male die during the dimpling process. Do not substitute another rivet, either of the same size or a size larger.Radius Dimpling

Radius dimpling uses special die sets that have a radius and are often used with stationary or portable squeezers. Dimpling removes no metal and, due to the nestling effect, gives a stronger joint than the non-flush type. A dimpled joint reduces the shear loading on the rivet and places more load on the riveted sheets.NOTE: Dimpling is also done for flush bolts and other flush fasteners.

Dimpling is required for sheets that are thinner than the minimum specified thickness for countersinking. However, dimpling is not limited to thin materials. Heavier parts may be dimpled without cracking by specialized hot dimpling equipment. The temper of the material, rivet size, and available equipment are all factors to be considered in dimpling. [Figure 14]

|

| Figure 14. Dimpling techniques |

Hot Dimpling

Hot dimpling is the process that uses heated dimpling dies to ensure the metal flows better during the dimpling process. Hot dimpling is often performed with large stationary equipment available in a sheet metal shop. The metal being used is an important factor because each metal presents different dimpling problems. For example, 2024-T3 aluminum alloy can be satisfactorily dimpled either hot or cold, but may crack in the vicinity of the dimple after cold dimpling because of hard spots in the metal. Hot dimpling prevents such cracking.7075-T6 aluminum alloys are always hot dimpled. Magnesium alloys also must be hot dimpled because, like 7075-T6, they have low formability qualities. Titanium is another metal that must be hot dimpled because it is tough and resists forming. The same temperature and dwell time used to hot dimple 7075-T6 is used for titanium.

100° Combination Predimple and Countersink Method

Metals of different thicknesses are sometimes joined by a combination of dimpling and countersinking. [Figure 15] A countersink well made to receive a dimple is called a subcountersink. These are most often seen where a thin web is attached to heavy structure. It is also used on thin gap seals, wear strips, and repairs for worn countersinks.Dimpling Inspection

To determine the quality of a dimple, it is necessary to make a close visual inspection. Several features must be checked. The rivet head should fit flush and there should be a sharp break from the surface into the dimple. The sharpness of the break is affected by dimpling pressure and metal thickness. Selected dimples should be checked by inserting a fastener to make sure that the flushness requirements are met. Cracked dimples are caused by poor dies, rough holes, or improper heating. Two types of cracks may form during dimpling:- Radial cracks—start at the edge and spread outward as the metal within the dimple stretches. They are most common in 2024-T3. A rough hole or a dimple that is too deep causes such cracks. A small tolerance is usually allowed for radial cracks.

- Circumferential cracks—downward bending into the draw die causes tension stresses in the upper portion of the metal. Under some conditions, a crack may be created that runs around the edge of the dimple. Such cracks do not always show since they may be underneath the cladding. When found, they are cause for rejection. These cracks are most common in hotdimpled 7075 T6 aluminum alloy material. The usual cause is insufficient dimpling heat.

Evaluating the Rivet

To obtain high structural efficiency in the manufacture and repair of aircraft, an inspection must be made of all rivets before the part is put in service. This inspection consists of examining both the shop and manufactured heads and the surrounding skin and structural parts for deformities. A scale or rivet gauge can be used to check the condition of the upset rivet head to see that it conforms to the proper requirements. Deformities in the manufactured head can be detected by the trained eye alone. [Figure 16] |

| Figure 16. Rivet defects |

Occasionally, during an aircraft structural repair, it is wise to examine adjacent parts to determine the true condition of neighboring rivets. In doing so, it may be necessary to remove the paint. The presence of chipped or cracked paint around the heads may indicate shifted or loose rivets. Look for tipped or loose rivet heads. If the heads are tipped or if rivets are loose, they show up in groups of several consecutive rivets and probably tipped in the same direction. If heads that appear to be tipped are not in groups and are not tipped in the same direction, tipping may have occurred during some previous installation.

Inspect rivets known to have been critically loaded, but that show no visible distortion, by drilling off the head and carefully punching out the shank. If, upon examination, the shank appears joggled and the holes in the sheet misaligned, the rivet has failed in shear. In that case, try to determine what is causing the shearing stress and take the necessary corrective action. Flush rivets that show head slippage within the countersink or dimple, indicating either sheet bearing failure or rivet shear failure, must be removed for inspection and replacement.

Joggles in removed rivet shanks indicate partial shear failure. Replace these rivets with the next larger size. Also, if the rivet holes show elongation, replace the rivets with the next larger size. Sheet failures such as tear-outs, cracks between rivets, and the like usually indicate damaged rivets. The complete repair of the joint may require replacement of the rivets with the next larger size.

The general practice of replacing a rivet with the next larger size (1⁄32-inch greater diameter) is necessary to obtain the proper joint strength of rivet and sheet when the original rivet hole is enlarged. If the rivet in an elongated hole is replaced by a rivet of the same size, its ability to carry its share of the shear load is impaired and joint weakness results.

Removal of Rivets

When a rivet has to be replaced, remove it carefully to retain the rivet hole’s original size and shape. If removed correctly, the rivet does not need to be replaced with one of the next larger size. Also, if the rivet is not removed properly, the strength of the joint may be weakened and the replacement of rivets made more difficult.When removing a rivet, work on the manufactured head. It is more symmetrical about the shank than the shop head, and there is less chance of damaging the rivet hole or the material around it. To remove rivets, use hand tools, a power drill, or a combination of both.

The procedure for universal or protruding head rivet removal is as follows:

- File a flat area on the head of the rivet and center punch the flat surface for drilling. NOTE: On thin metal, back up the rivet on the upset head when center punching to avoid depressing the metal.

- Use a drill bit one size smaller than the rivet shank to drill out the rivet head. NOTE: When using a power drill, set the drill on the rivet and rotate the chuck several revolutions by hand before turning on the power. This procedure helps the drill cut a good starting spot and eliminates the chance of the drill slipping off and tracking across the metal.

- Drill the rivet to the depth of its head, while holding the drill at a 90° angle. Do not drill too deeply, as the rivet shank will then turn with the drill and tear the surrounding metal. NOTE: The rivet head often breaks away and climbs the drill, which is a signal to withdraw the drill.

- If the rivet head does not come loose of its own accord, insert a drift punch into the hole and twist slightly to either side until the head comes off.

- Drive the remaining rivet shank out with a drift punch slightly smaller than the shank diameter.

On thin metal or unsupported structures, support the sheet with a bucking bar while driving out the shank. If the shank is unusually tight after the rivet head is removed, drill the rivet about two-thirds through the thickness of the material and then drive the rest of it out with a drift punch. Figure 17 shows the preferred procedure for removing universal rivets.

|

| Figure 17. Rivet removal |

To remove a countersunk or flush head rivet, you must:

- Select a drill about 0.003-inch smaller than the rivet shank diameter.

- Drill into the exact center of the rivet head to the approximate depth of the head.

- Remove the head by breaking it off. Use a punch as a lever.

- Punch out the shank. Use a suitable backup, preferably wood (or equivalent), or a dedicated backup block. If the shank does not come out easily, use a small drill and drill through the shank. Be careful not to elongate the hole.